Safe and rapid tunneling process for high-outburst mine coal roadway

A technology for mines and coal roadways, which is applied in the field of safe and rapid excavation of coal roadways in high outburst mines, can solve problems such as gas outburst, and achieve the effects of improving production efficiency, saving supporting materials, and improving blasting effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

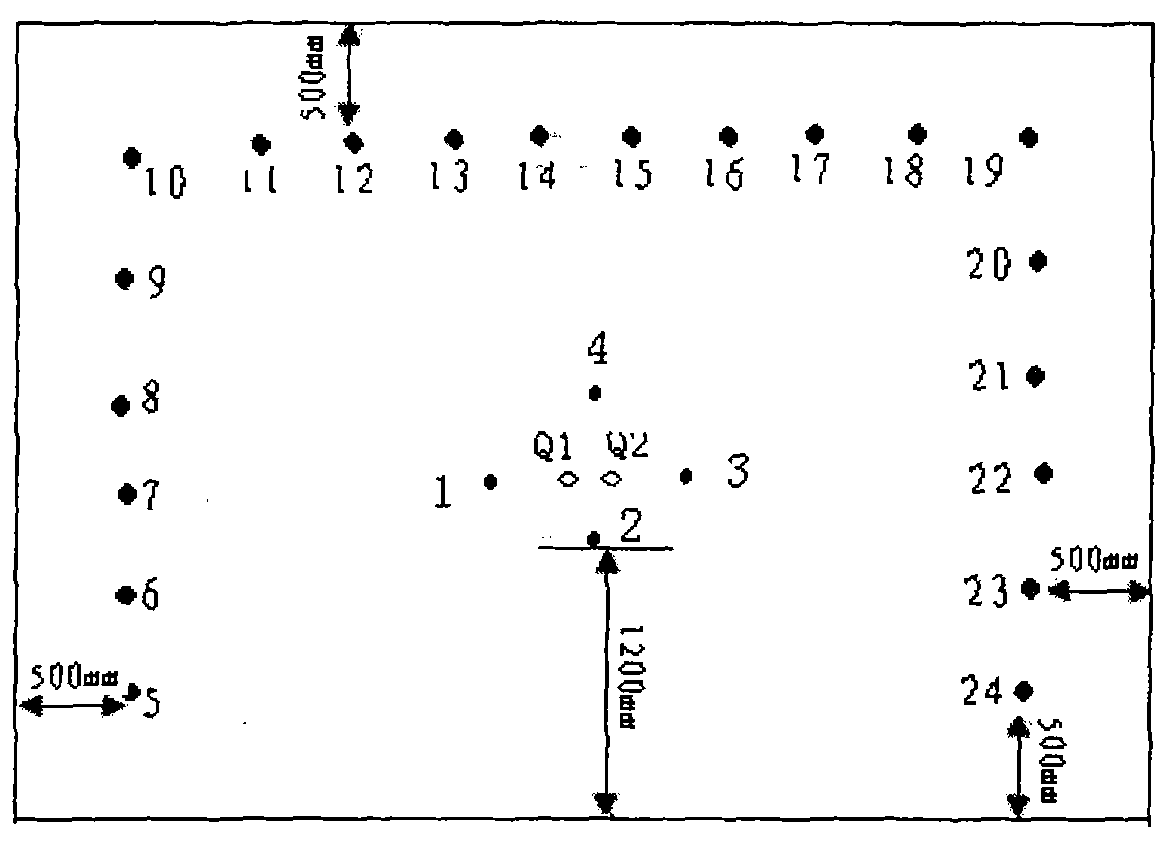

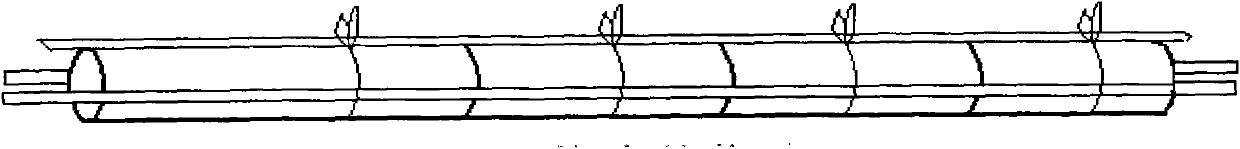

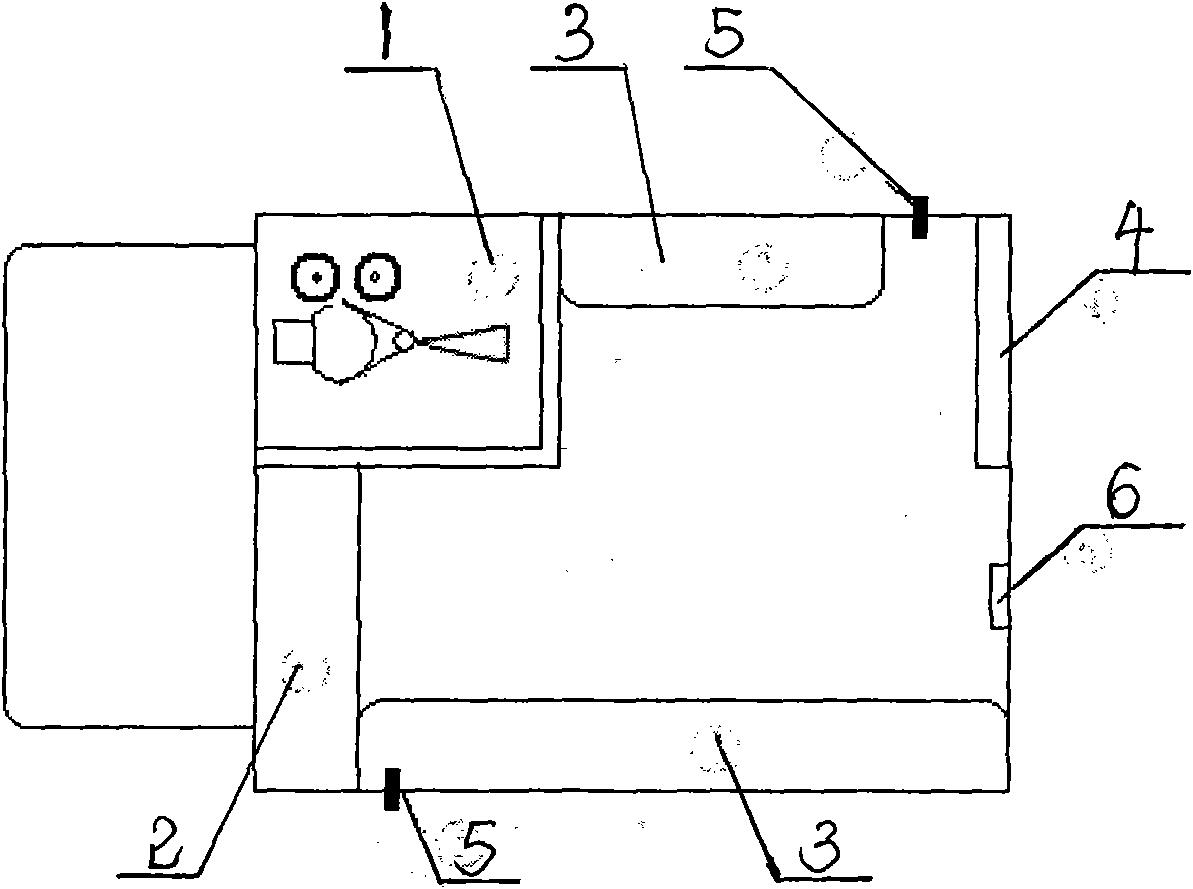

[0018] A safe and rapid excavation process for coal lanes in high outburst mines. The steps are: coal body prediction by bench drilling rig, construction of blasthole by bench drilling machine, charging and blasting, waiting for 30mim after blasting, entering the working face unit to discharge coal, bench drilling machine supporting, and the next cycle In the process, the blasting hole adopts the straight-hole cutting method of diamond-shaped cutting, and two large-diameter hollow holes are constructed in the middle of the diamond-shaped hole. The blasting cycle is controlled between 4m-6m. The blastholes are controlled to be detonated in groups according to the predetermined sequence. Before the detonation, the personnel withdraw from a safe distance and hide in the explosion-proof mobile refuge chamber vehicle. Bench drilling rig is a kind of commonly used equipment in coal mines, which has the functions of drilling and supporting.

[0019] Rhombus straight eye cut such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com