Cylindrical roller bearing with block

A cylindrical roller bearing with seat technology, applied in the direction of roller bearings, bearing components, shafts and bearings, etc., can solve problems such as assembly difficulties, and achieve the effect of simplifying the assembly process, improving the quality of lubrication, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

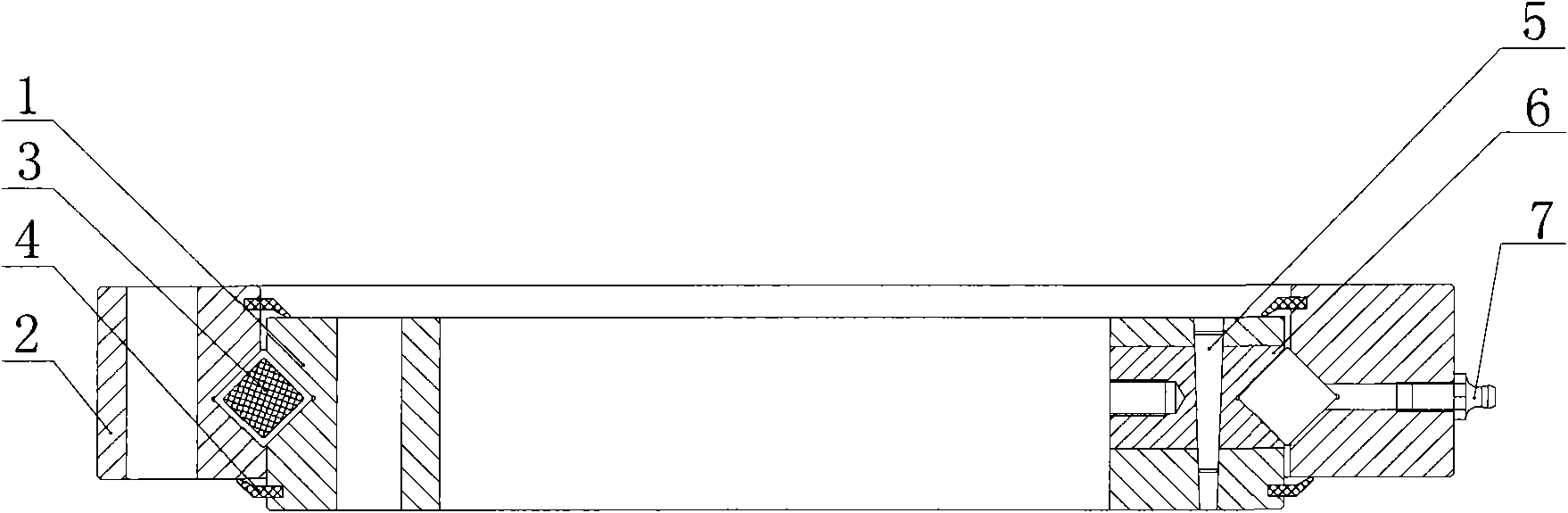

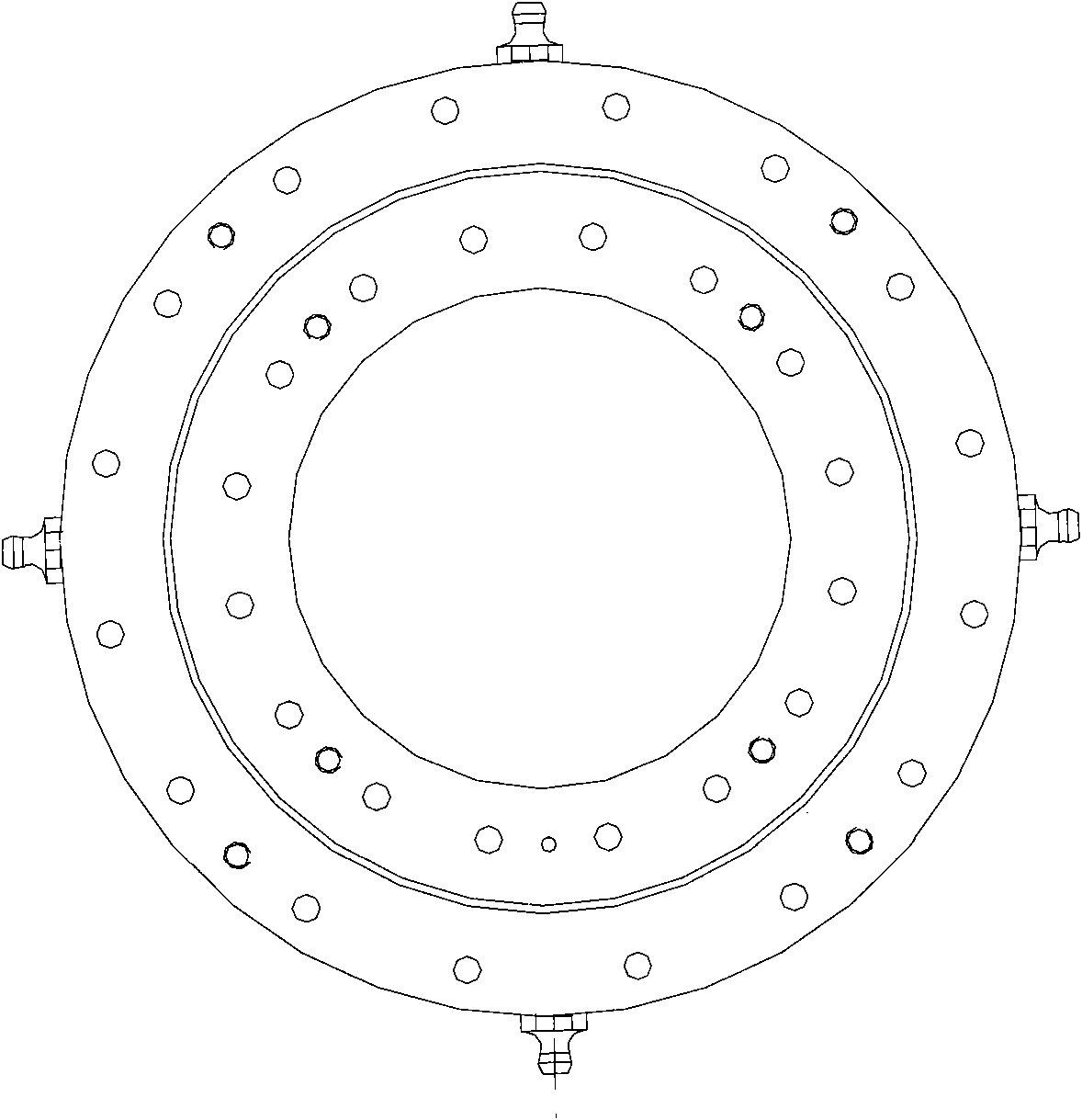

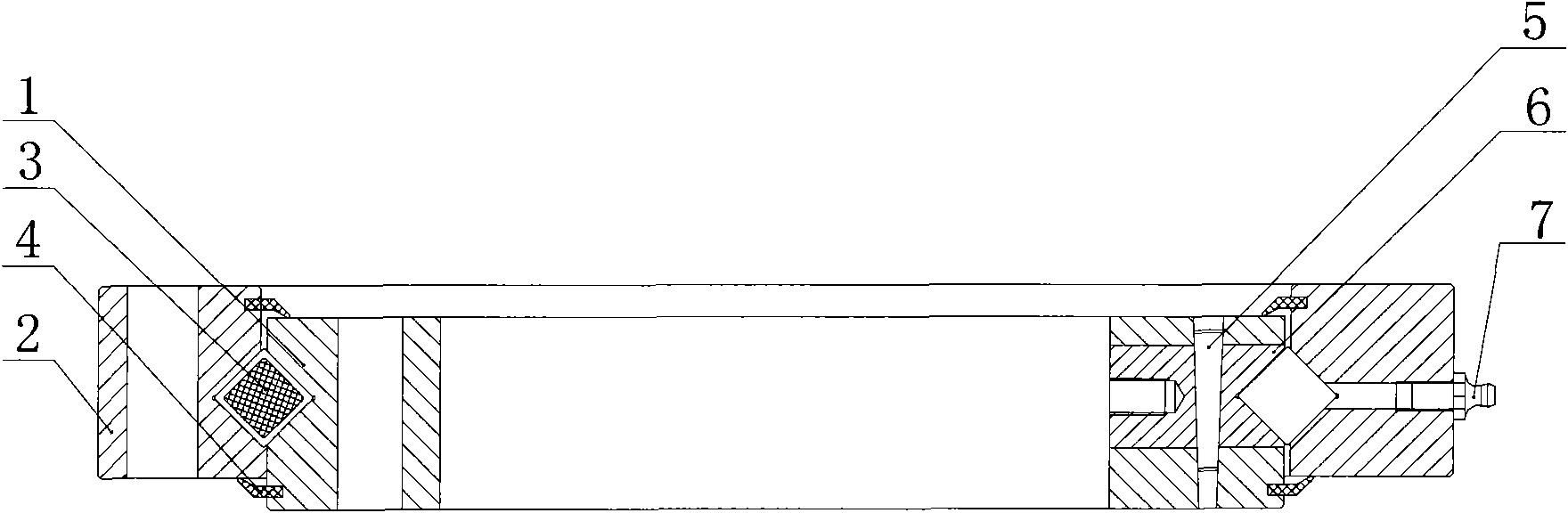

[0010] The present invention as figure 1 with figure 2 As shown, it includes inner ring 1, outer ring 2, roller 3 and sealing ring 4; outer ring 2 is set on inner ring 1, roller 3 is installed between outer ring 2 and inner ring 1, outer ring 2 The space between the rings 1 is sealed by the sealing ring 4 .

[0011] Wherein, the middle part of the outer ring 2 is provided with a threaded hole in the radial direction, and the connecting seat 7 is fixed through the threaded hole; the connecting seat 7 includes a threaded column at one end and a spherical rotary structure with a large head and a small neck at the other end. In a preferred manner, four threaded holes are evenly distributed on the outer ring 2 at intervals of 90 degrees in the circumferential direction, and thus the four connecting seats 7 are fixed.

[0012] In addition, the improvement of the present invention lies in the installation method of the rollers, wherein, one side of the circumference of the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com