Workpiece leveling and centering device

A technology for self-aligning and workpiece, applied in the field of self-aligning device, position adjusting device and workpiece leveling, can solve the problems affecting measurement efficiency and measurement accuracy, and achieve the effects of quick adjustment response, convenient operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

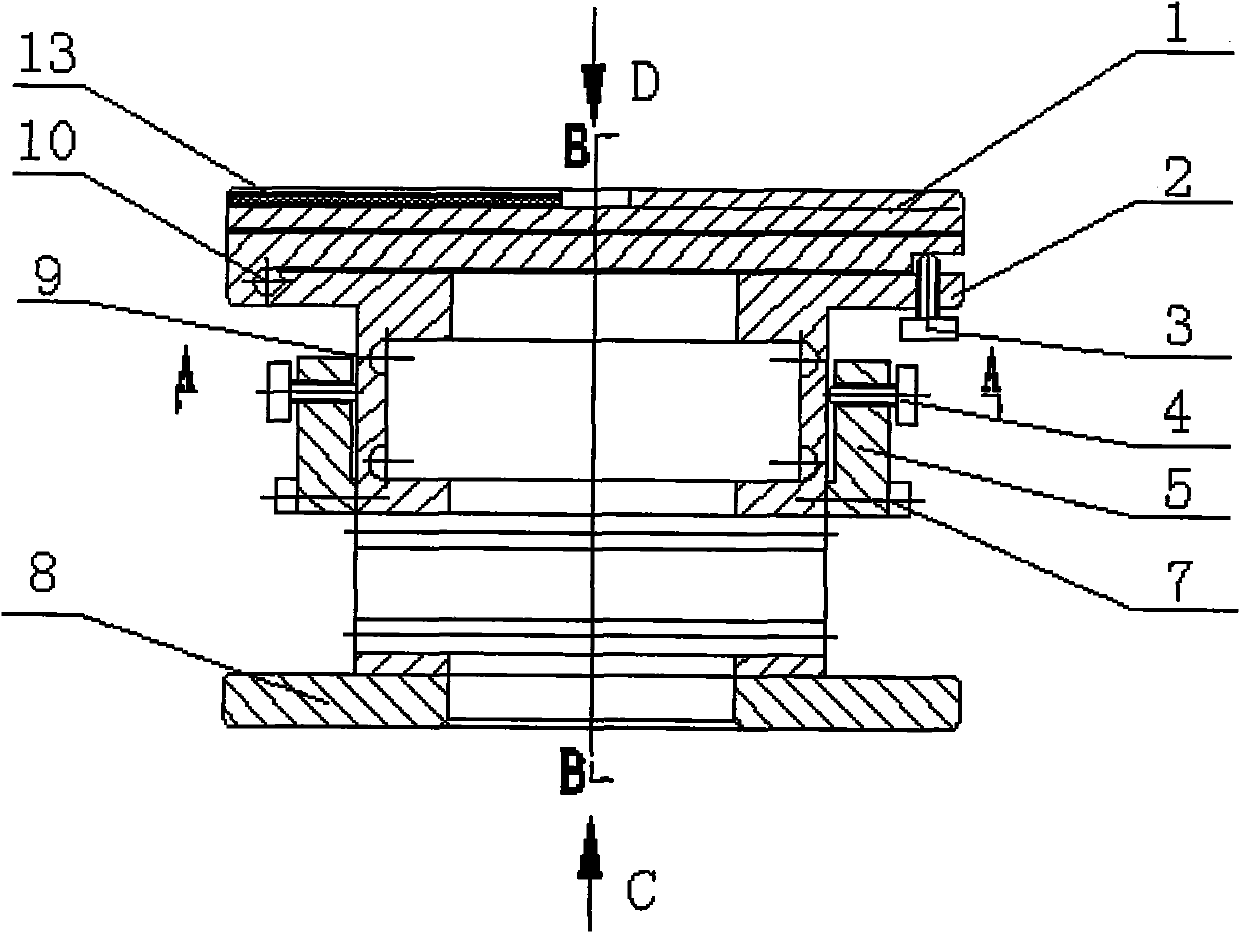

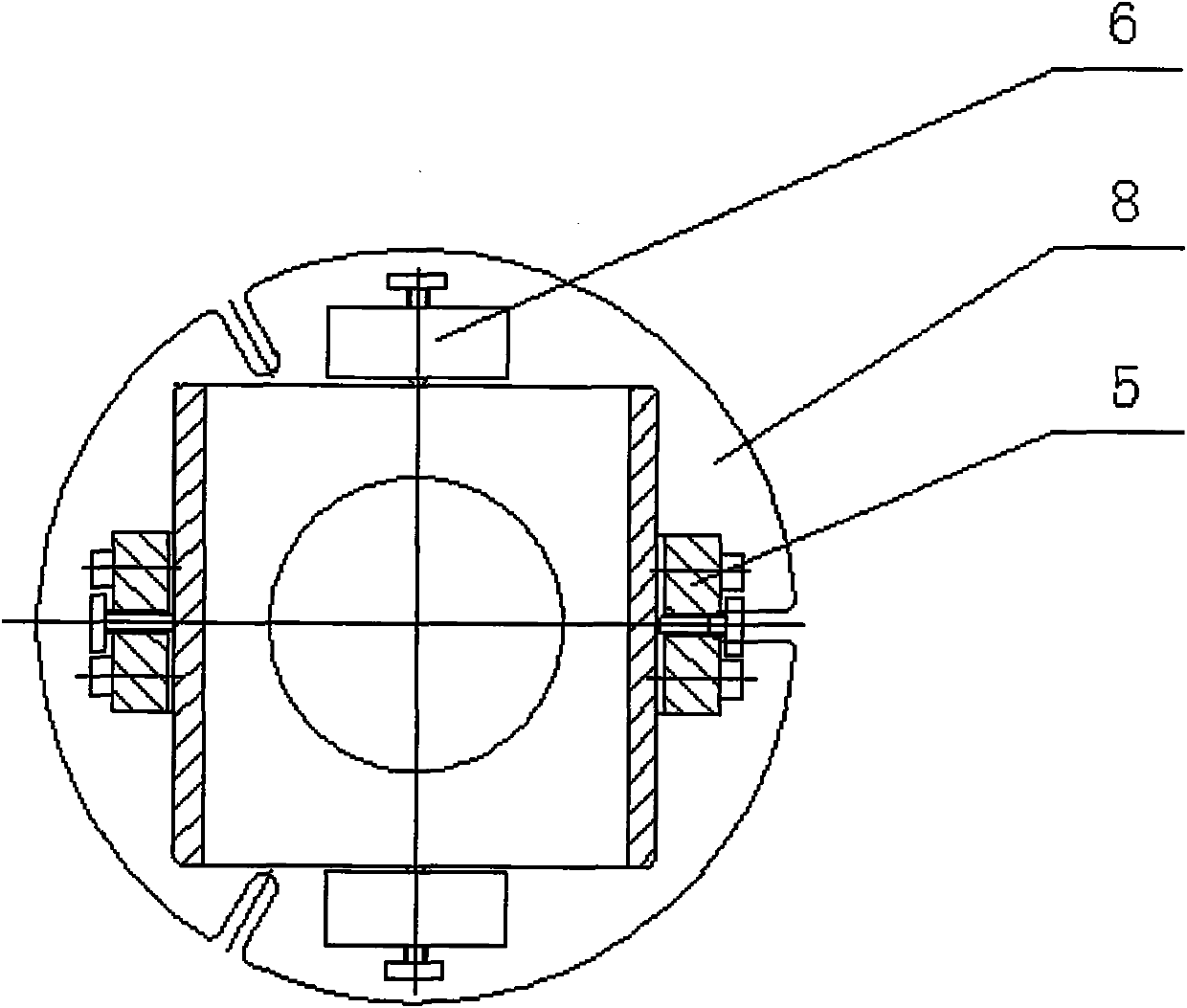

[0023] see Figure 1-Figure 5 , a workpiece leveling and centering device, including a magnetic strip 13, an adjustment body and a chassis 8, the chassis 8 outer periphery has three longitudinally through U-shaped notches 12 for installation on a testing platform. The adjustment body is composed of a lotus leaf hinge 1 and a column hinge 9. Three magnetic strips 13 are inlaid on the lotus leaf surface of the lotus leaf hinge 1. The magnetic strips 13 are arranged radially and uniformly. The center of the lotus leaf surface is provided with a centering hole 15, and the magnetic strip 13 is located at the periphery of the centering hole 15. The magnetic strip 13 is used to fix the workpiece to be measured, and the centering hole 15 is convenient for realizing centering; the lower end of the column hinge 9 is composed of four The screws are fixed on the chassis 8 through fastening screw holes 11 .

[0024] In this embodiment, the column hinge 9 is a well-known column structure w...

Embodiment 2

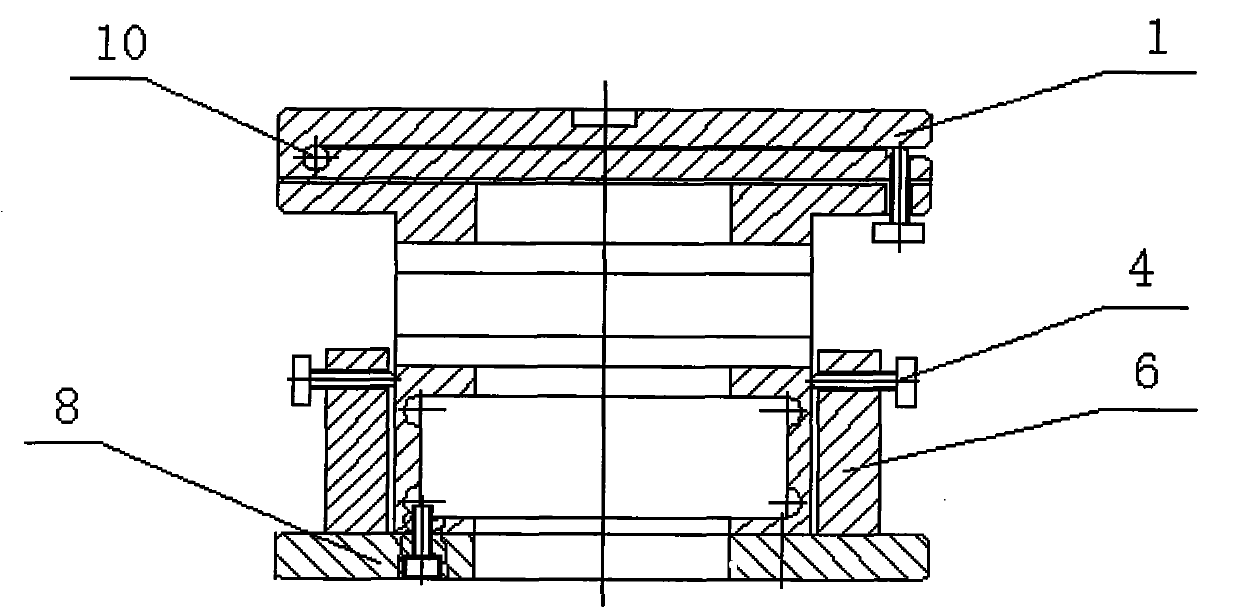

[0027] see Image 6 , and the difference from embodiment 1 is that the column hinge is composed of upper, middle and lower three-layer columns, and the upper, middle and lower three-layer columns are respectively provided with relative upper centering baffles 5 and middle centering baffles 14 With the lower centering baffle 6, the three-layer self-aligning baffles correspond to each other in pairs in the vertical space, and the adjacent self-aligning baffles form an angle of 60° in the plane space of the top view, and each self-aligning baffle is provided with a corresponding Self-aligning screw 4. After the workpiece is leveled by the lotus-leaf hinge, adjust a pair of self-aligning screws on the y-axis of the upper column of the column hinge, so that the upper column hinge can drive the lotus-leaf hinge to move in the direction of the y-axis, and the center of the workpiece can be adjusted to The origin of the y-axis, and then adjust the self-aligning screws of the middle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com