Deboner

A technology of bone and meat separation and separation part, which is applied in the field of bone and meat separators, can solve the problems of trivial work, low production efficiency, and high labor intensity, and achieve the effects of reducing direct contact, high production efficiency, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

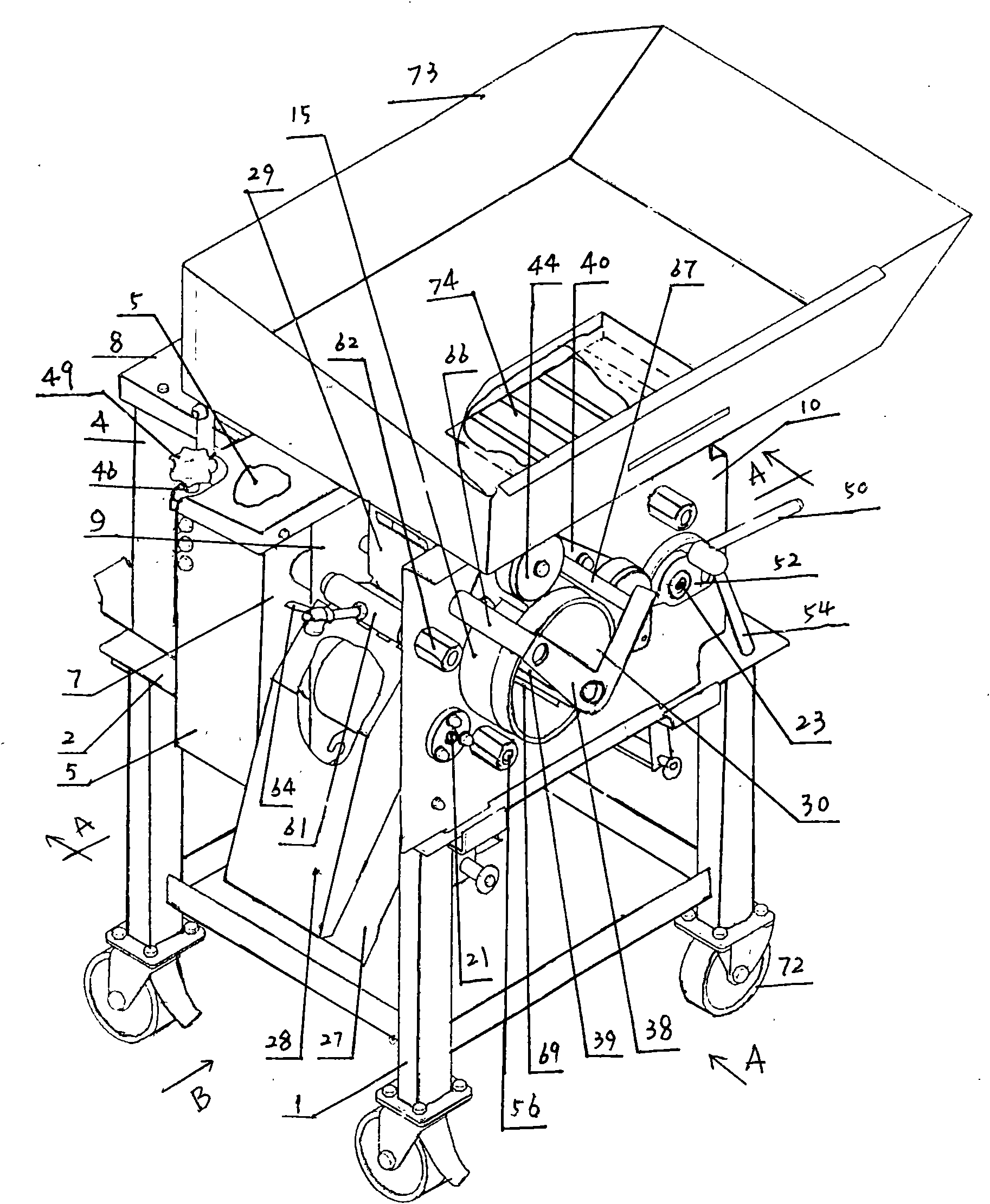

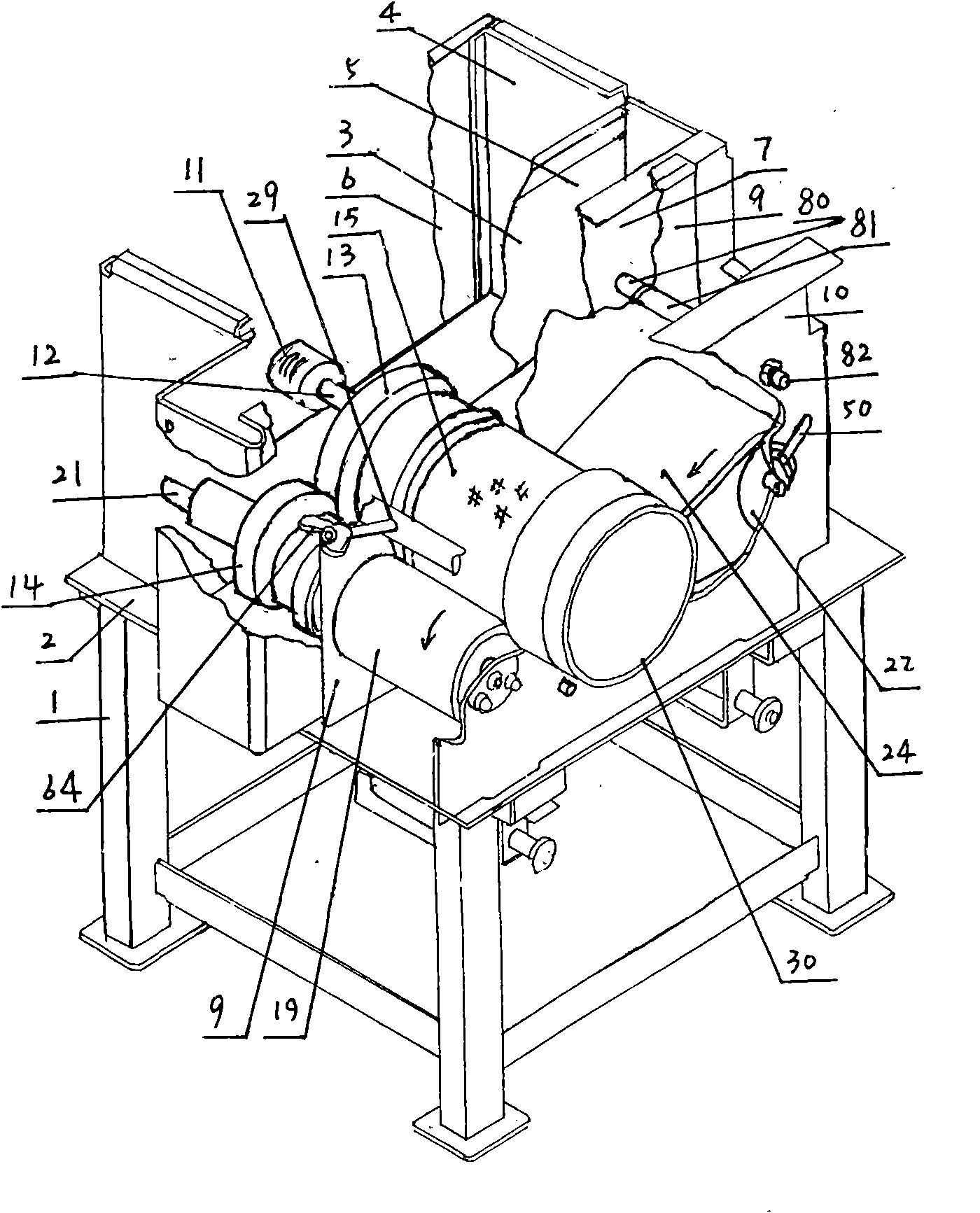

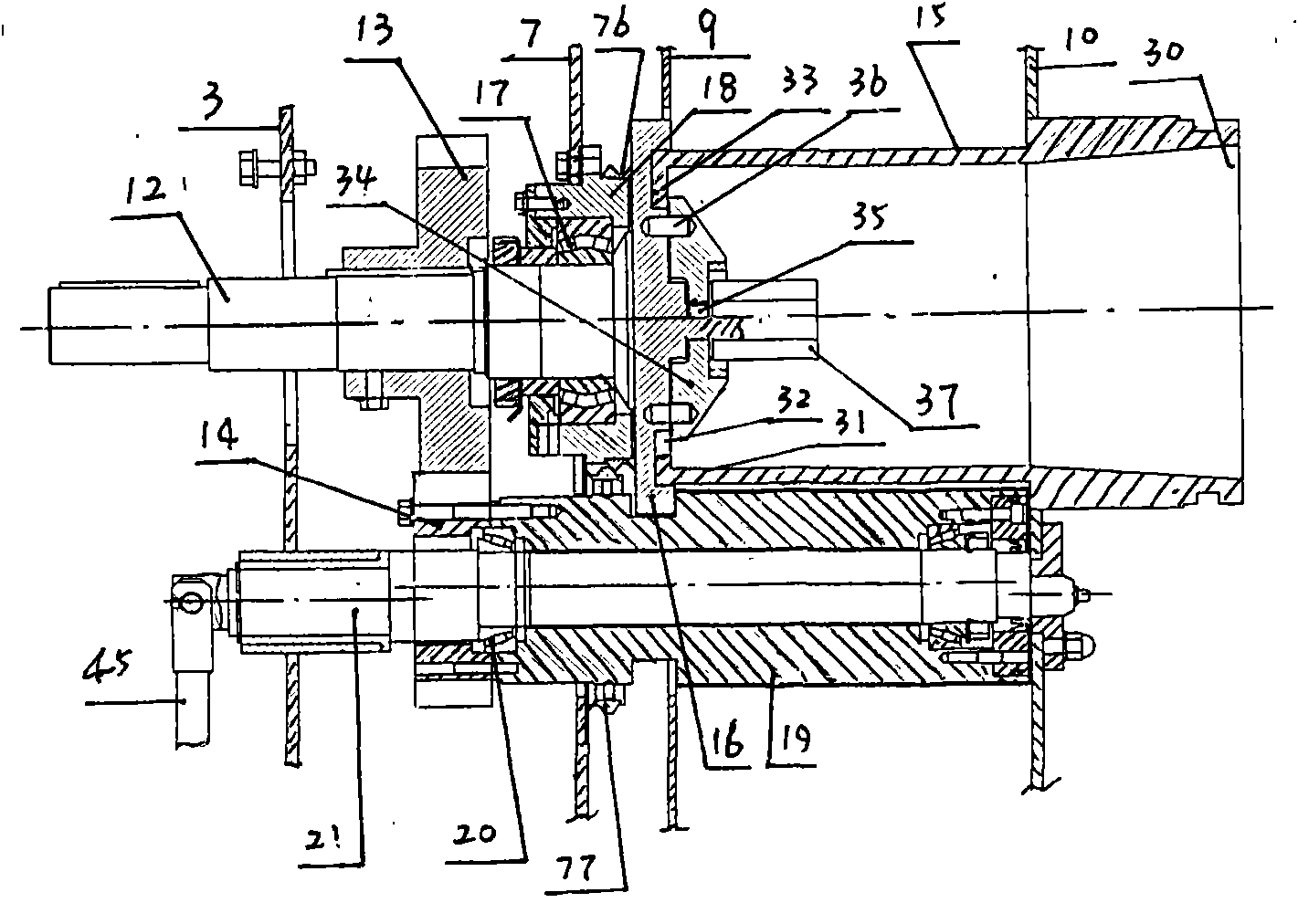

[0025] Further detailed description in conjunction with the accompanying drawings, the single arrow in the figure shows the direction of rotation and transmission in normal operation, and the double arrow shows the direction of material, bone and meat;

[0026] Such as figure 1 , 2 As shown, the frame is composed of a four-legged chassis 1, a main box body 4 and an auxiliary box body 5 sharing a middle plate 3 are mounted on the top bottom plate 2, and the main box body 4 has a detachable rear Sealing plate 6, auxiliary box body 5 has front sealing plate 7, and has supporting case cover 8; The outer side of front sealing plate 7 has adjacent dividing plate 9, also has front end plate 10, and dividing plate 9 and front end plate 10 are all connected with The bottom plate 2 is matched and closely related to the separation part and the discharge part. The front end plate 10 and the bottom plate 2 are detachably connected together. Mechanism; caster 72 is also housed on the unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com