Step-type multi-step silicon material cleaning equipment

A cleaning equipment and a step-by-step technology, applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as environmental pollution and large water consumption, and achieve waste reduction, cleaning cost reduction, and energy saving water effect noticeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

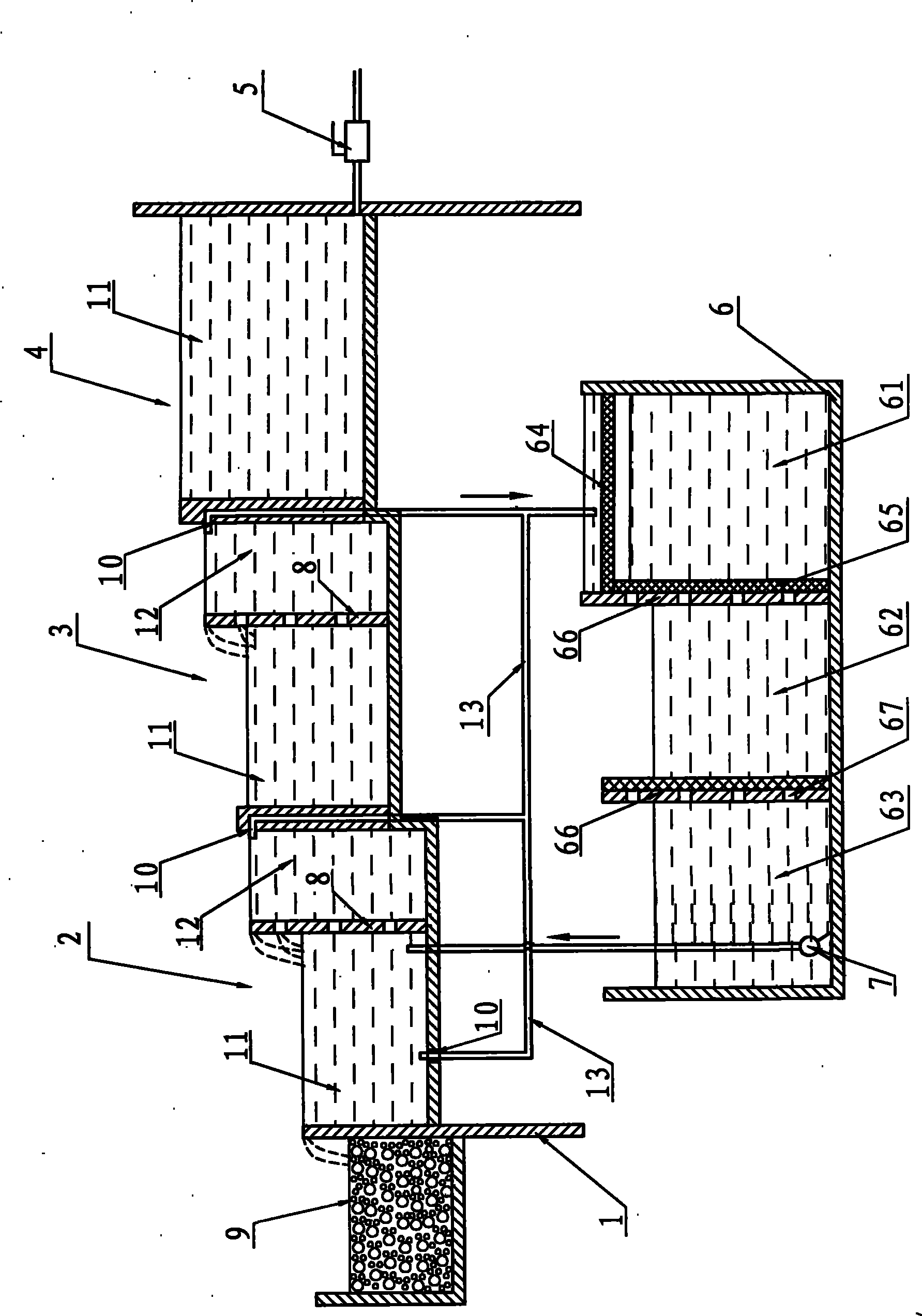

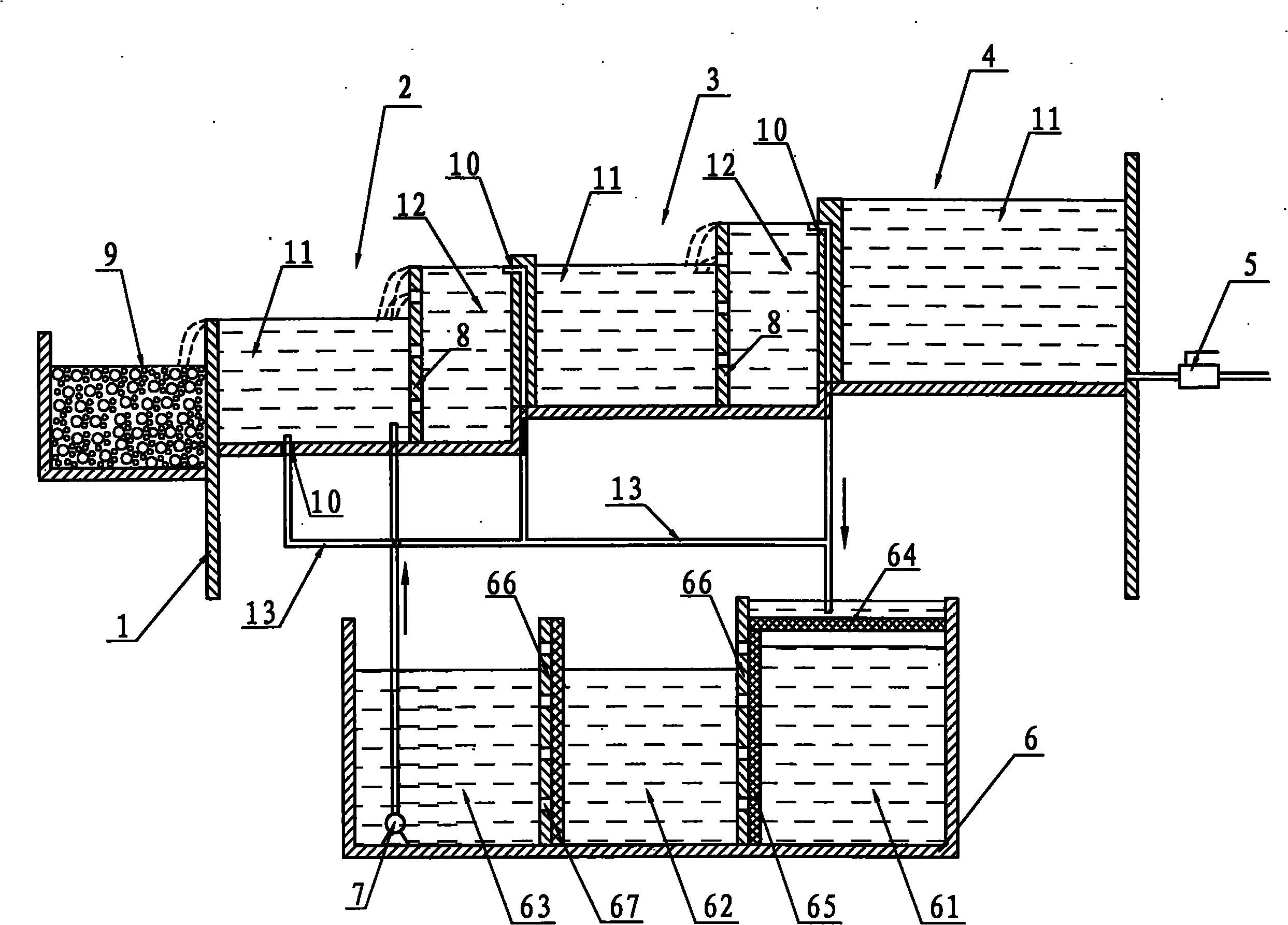

[0013] The stepped multi-stage silicon material cleaning equipment of the present invention is as attached figure 1 As shown, it includes frame 1, primary cleaning tank 2, transitional cleaning tank 3, final cleaning tank 4, water inlet valve 5, filter treatment tank 6, circulation pump 7, separation net plate 8 and dirty liquid tank 9, dirty liquid Tank 9, primary cleaning tank 2, transitional cleaning tank 3 and final cleaning tank 4 are arranged on the frame 1 sequentially from left to right. The side wall of the cleaning tank 3 is provided with a backflow hole 10, and the backflow hole 10 communicates with the filter treatment tank 6 through a hose 13; a partition screen 8 is provided in the transition cleaning tank 3, and the partition screen 8 will transition the cleaning The tank 3 is divided into a cleaning chamber 11 and an overflow chamber 12, the overflow chamber 12 is adjacent to the final cleaning tank 4, and the height of the separating screen 8 is higher than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com