Slow cooling device for reducing bottom warp of aluminum alloy ingot

A technology of aluminum alloy ingot casting and slow cooling device, applied in the field of slow cooling device, can solve the problems of high alloying element content, low resistance to bottom warpage, small plastic zone of the ingot, etc., achieving significant economic benefits and avoiding bottom warping. the effect of reducing the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] After an in-depth analysis of the warping mechanism, combined with casting process exploration and continuous improvement of the casting machine system, the present invention designs a method for alleviating the warping deformation at the bottom of the aluminum alloy ingot, reducing the cooling intensity at the bottom of the ingot, Improve the uniformity of cooling at the bottom of the ingot, ensure stable casting and forming at the initial stage of casting, and improve the pass rate of products.

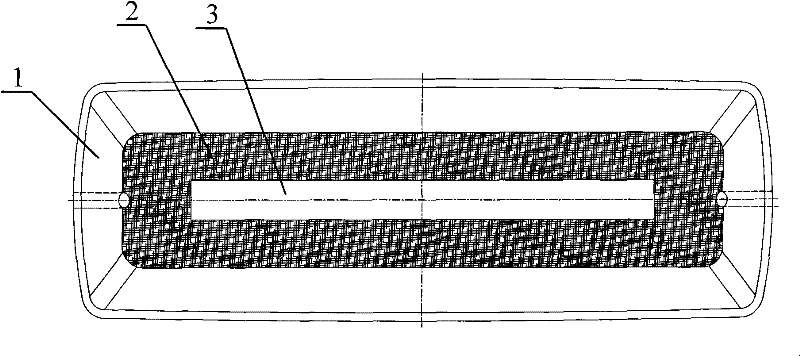

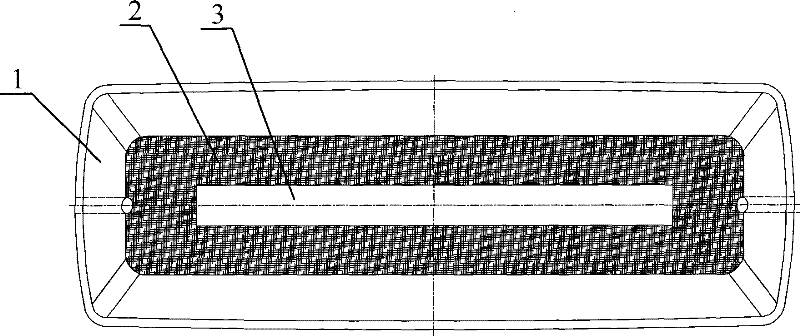

[0017] Such as figure 1 As shown, the slow cooling device used to reduce the warping of the bottom of the aluminum alloy ingot, including the dummy head 1 and the thermal insulation film 2, the material of the thermal insulation film 2 is silicon felt, the outer edge of the thermal insulation film 2 and the bottom surface of the dummy head 1 The shape is consistent, and it is a hyperboloid. The middle part of the thermal insulation film 2 is a cavity 3. The shape of the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com