Redundant-drive three-shaft series-parallel rotary platform

A three-axis turntable, parallel technology, used in large fixed members, metal processing mechanical parts, instruments, etc., can solve the problems of difficult to bear heavy load, structural asymmetry, singular mechanism, etc., and achieve high dynamic response performance, structural symmetry stiffness High, simple and symmetrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

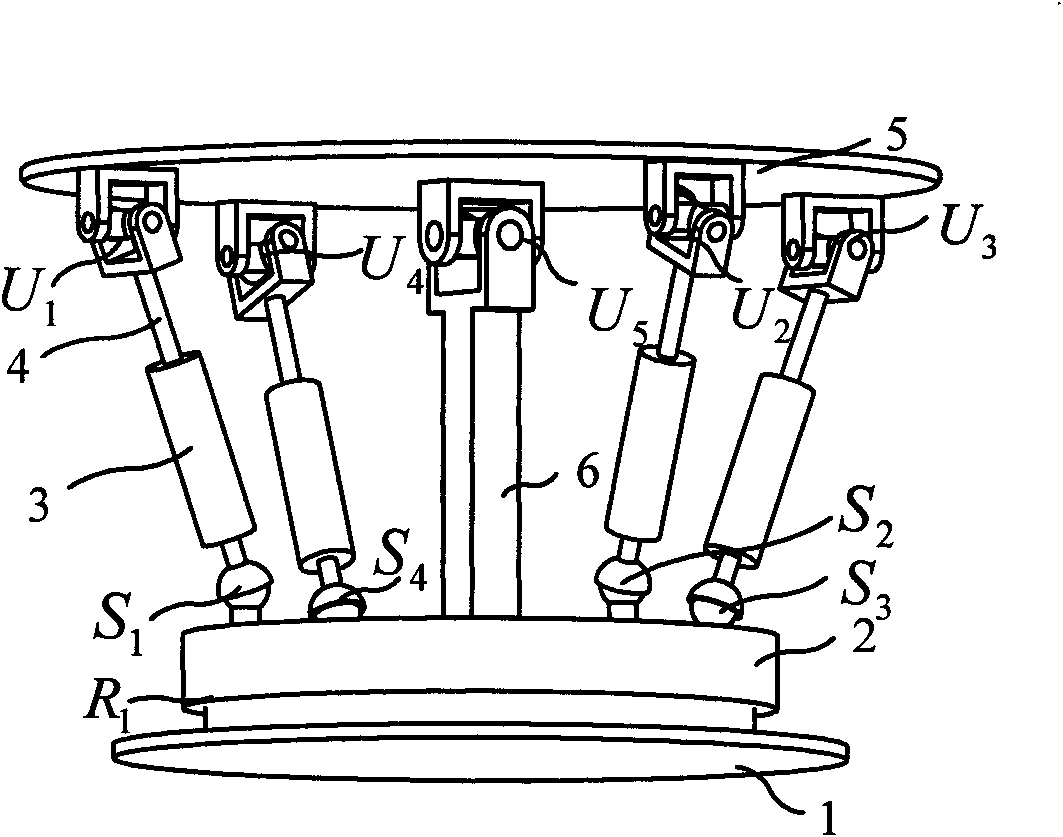

[0016] The redundant drive series-parallel three-axis turntable of this embodiment is as follows: figure 1 As shown, the series-parallel turntable is composed of a base platform 1, a middle platform 2, an upper platform 5, four driving branches distributed around, and a middle constraint branch. The middle constraint branch is fixedly connected to the middle platform 2 and passed through the fifth universal hinge U 5 Connected with the upper platform 5, the fifth universal hinge U 5 The axis of the rotating pair connecting the upper platform 5 is parallel to the table top of the upper platform 5, and the fifth universal joint U 5 Connect the rotating pair axis of the intermediate support rod 6 with the first rotating pair R 1 The axis is vertical; the four drive branches are all composed of cylinder 3 and connecting rod 4, the cylinder 3 and connecting rod 4 are connected by a moving pair, and the cylinder 3 and the middle platform 2 pass through the upper universal hinge (t...

Embodiment 2

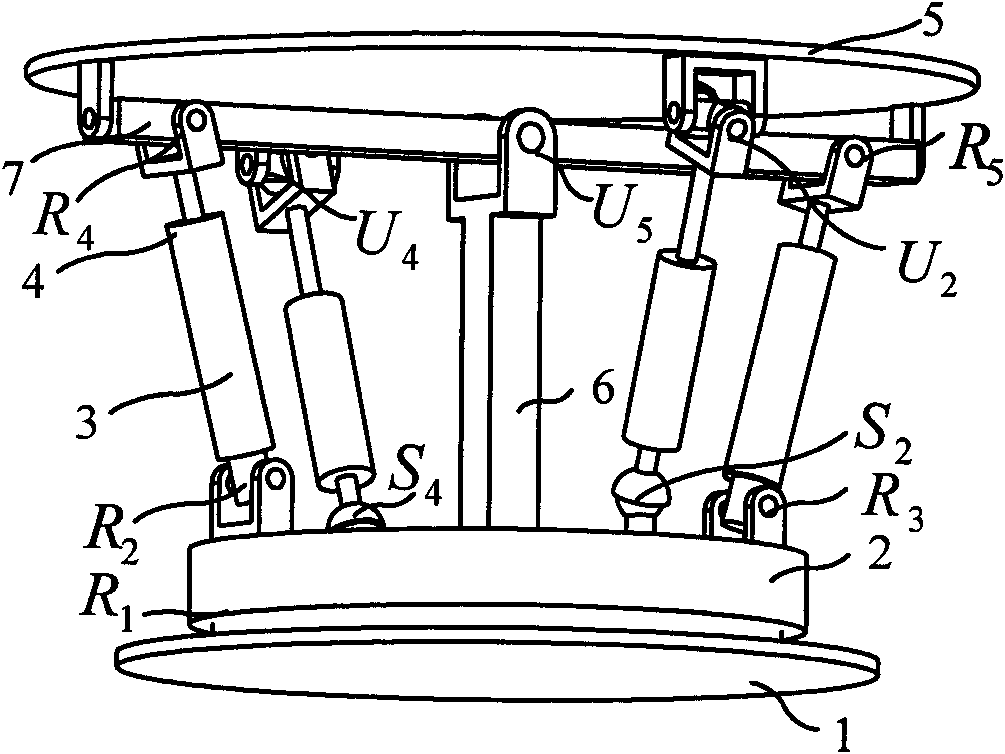

[0018] The redundant drive series-parallel three-axis turntable of this embodiment is as follows: figure 2 As shown, the series-parallel turntable is composed of a base platform 1, a middle platform 2, an upper platform 5, four driving branches distributed around, and a middle constraint branch. The middle constraint branch is fixedly connected to the middle platform 2 and passed through the fifth universal hinge U 5 Connected with the upper platform 5, the fifth universal hinge U 5 The axis of the rotating pair connecting the upper platform 5 is parallel to the table top of the upper platform 5, and the fifth universal joint U 5 Connect the rotating pair axis of the intermediate support rod 6 with the first rotating pair R 1 The axis is vertical; the four drive branches are all composed of a cylinder 3 and a connecting rod 4, and the cylinder 3 and the connecting rod 4 are connected by a moving pair, and the two symmetrically arranged connecting rods 4 pass through the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com