Crevasse creasing machine for honeycomb paperboards

A honeycomb paperboard and creasing machine technology, applied in the direction of mechanical processing/deformation, can solve the problems of difficulty in ensuring product quality and stable performance, difficulty in meeting large-scale packaging, and high labor intensity, saving assembly glue and reducing stickiness. The effect of increasing workload and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

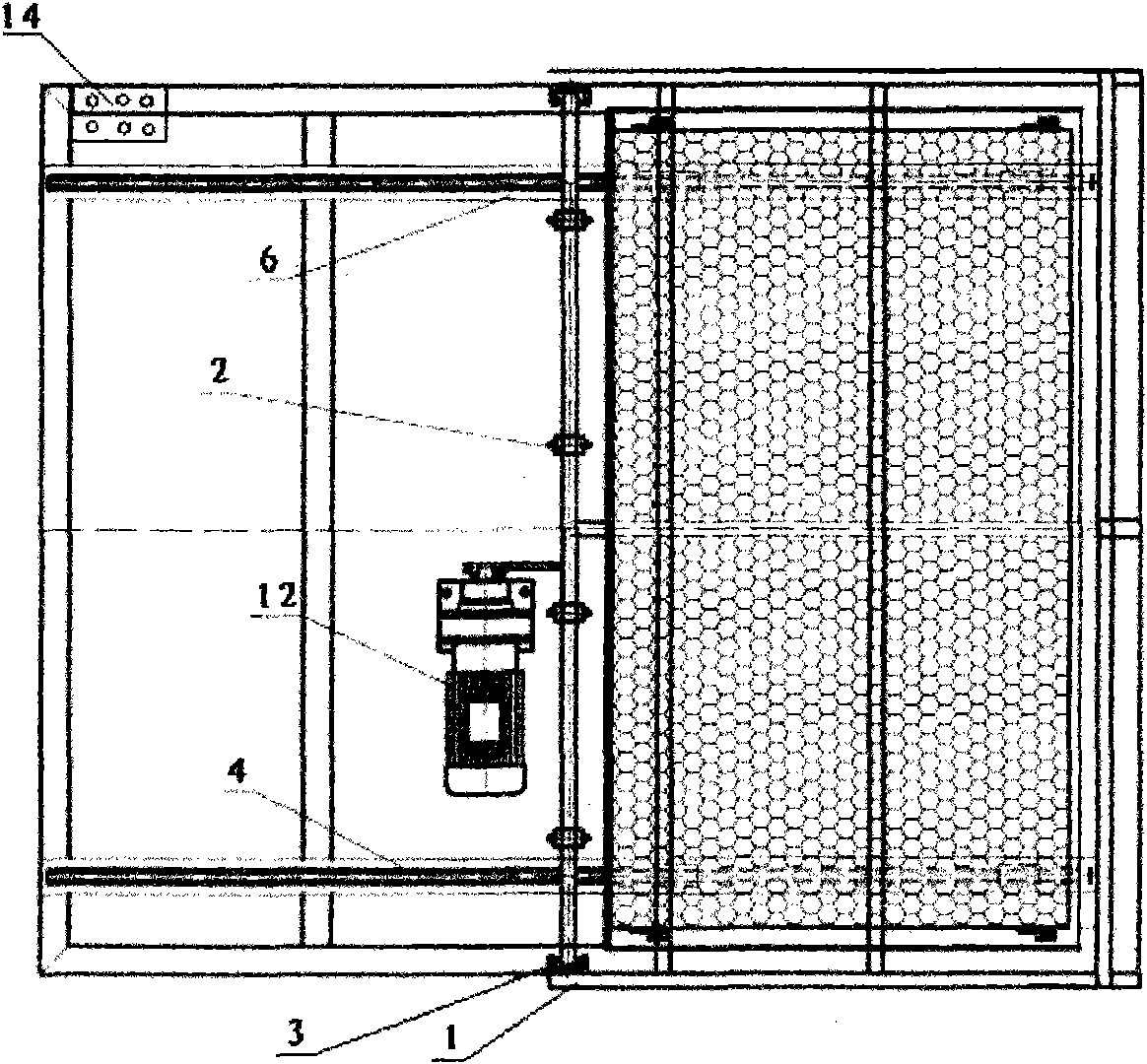

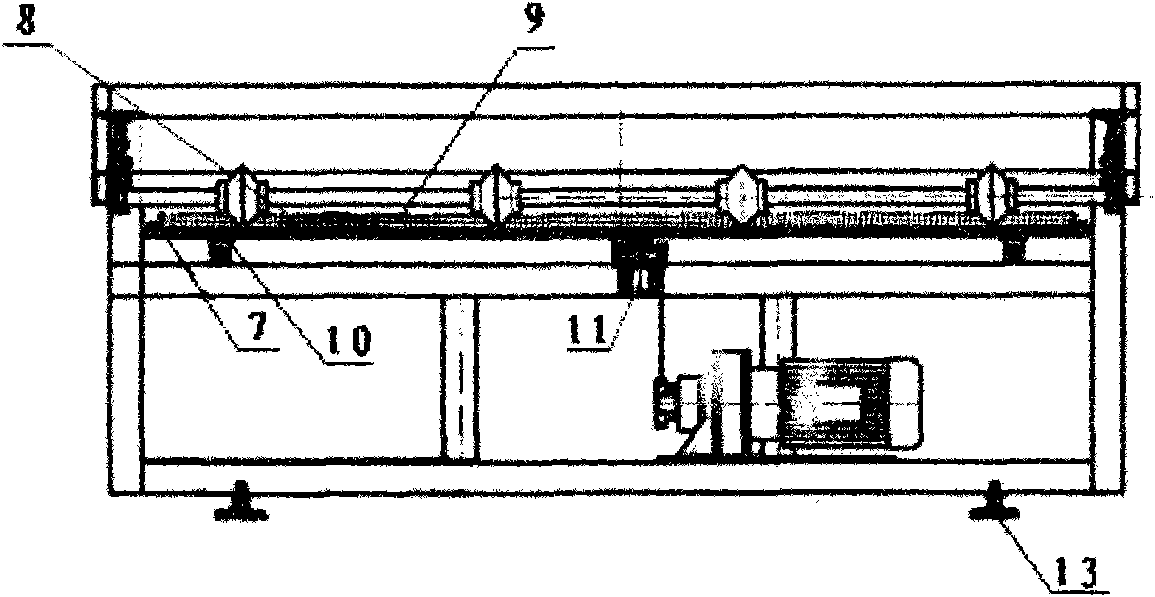

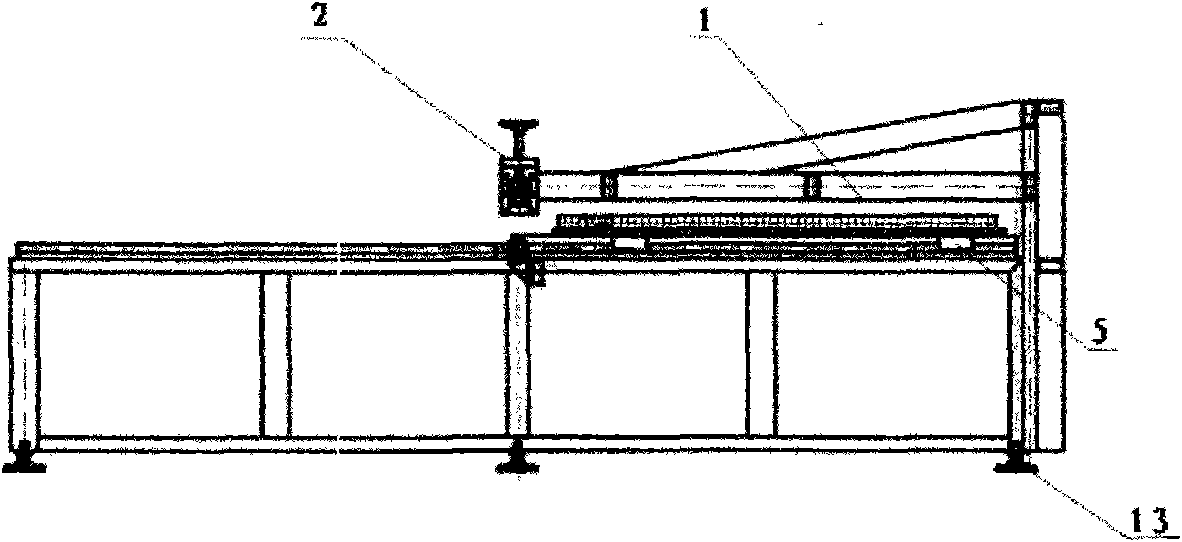

[0016] see Figure 1~3 , front view, left view and front view of honeycomb cardboard crease creasing machine, mainly including integrated working cutter head support 1, integrated working cutter head 2, screw adjustment seat assembly 3, linear slide rail 4, linear bearing 5, sliding Rail floor 6, worktable 7, buffer rubber pad mouth 8, indentation pressure wheel positioning scale 9, limit switch 10, bearing seat 11, reducer 12, adjustment seat 13, combined electrical control switch 14, etc., this embodiment It is an embodiment of a honeycomb paperboard breach creasing machine.

[0017] The integrated working cutter head support 1 is equipped with an integrated working cutter head 2, and a screw adjusting seat assembly 3 is installed on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com