High-strength high-flexibility low-yield-ratio fire resistant steel and production method thereof

A manufacturing method and refractory technology, applied in the field of low alloy steel manufacturing, can solve the problems of high alloying element content and low strength level of refractory steel, and achieve the effects of simple production process, low cost, good toughness and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

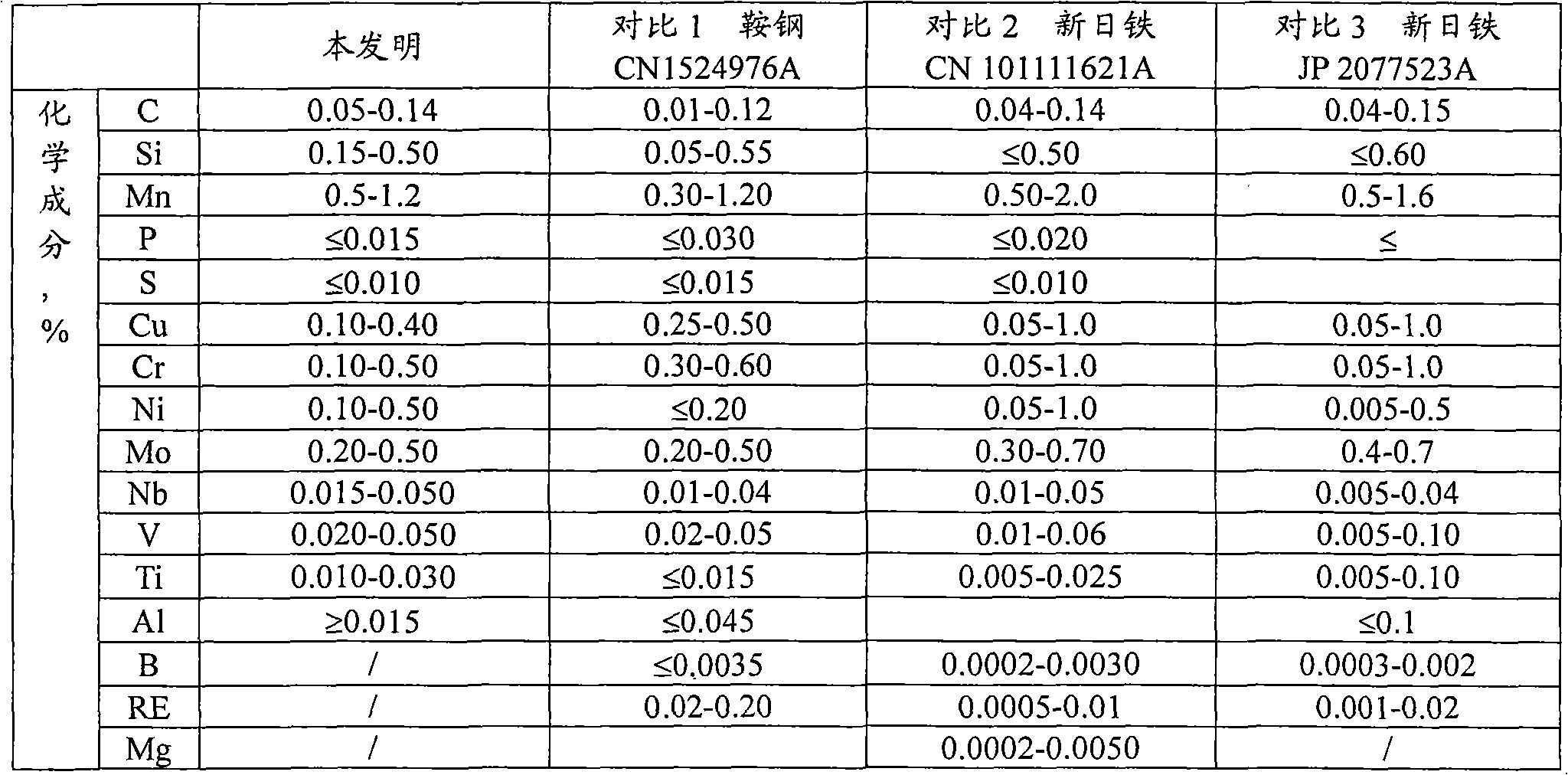

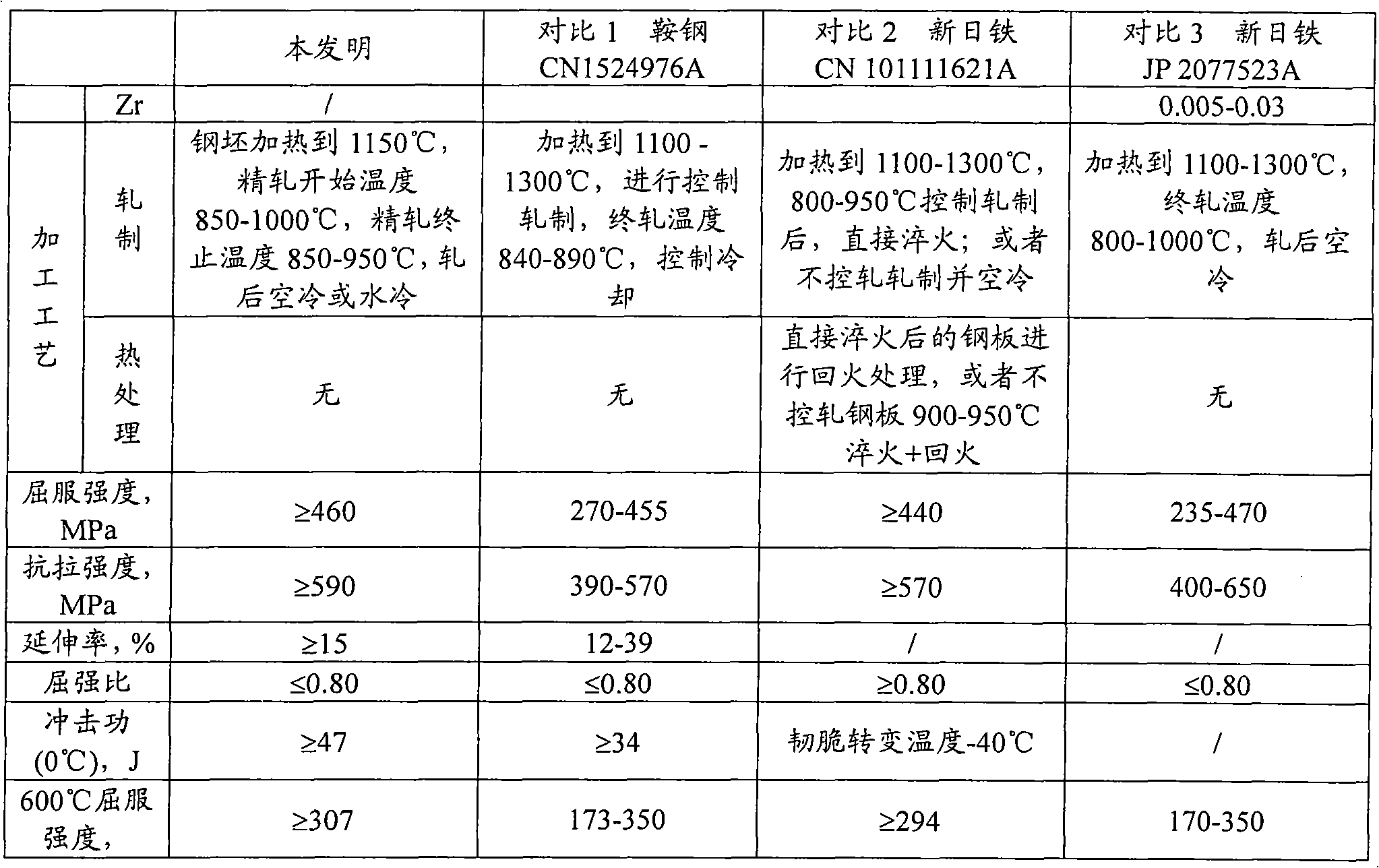

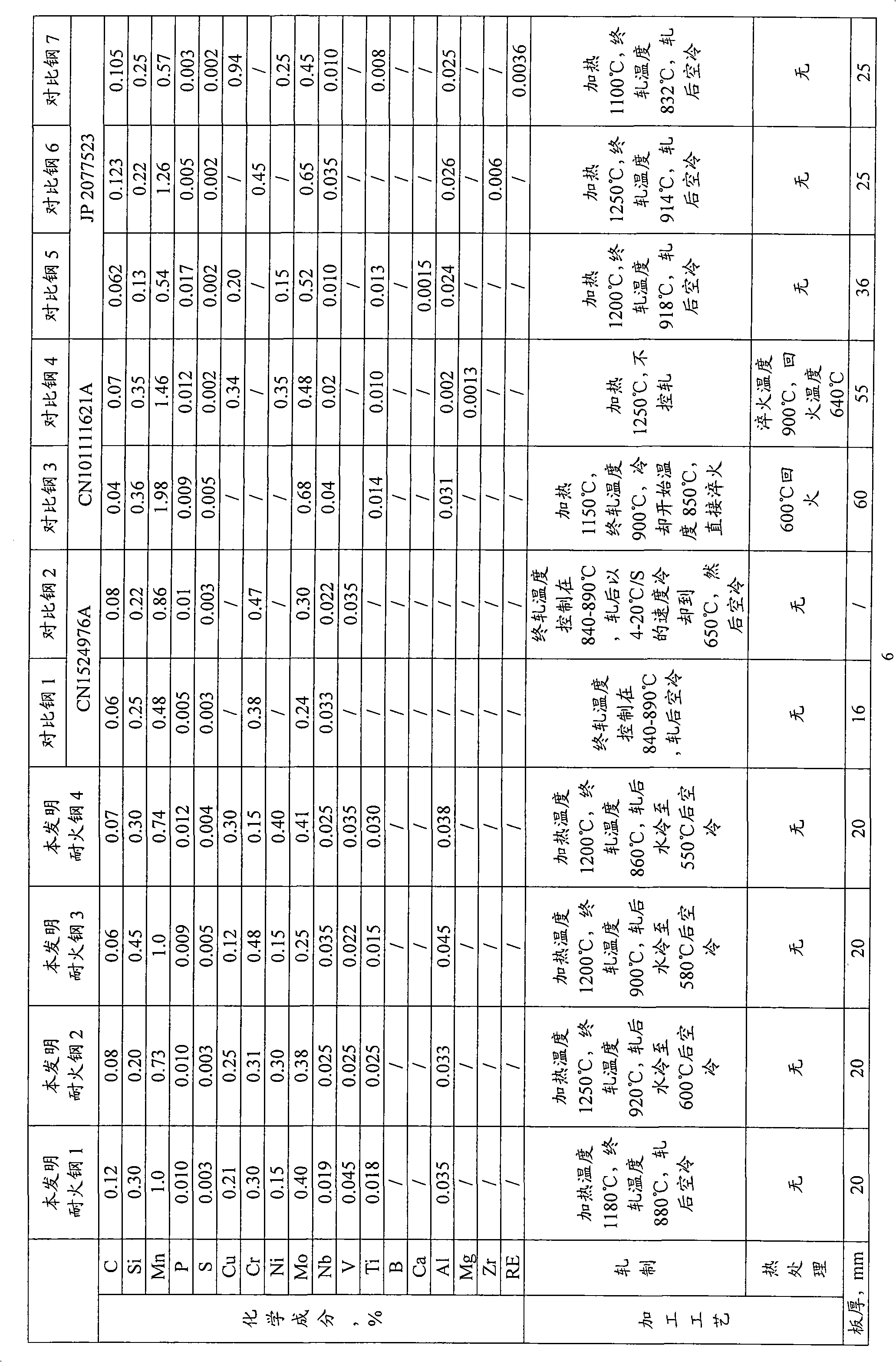

[0029] According to the chemical composition requirements of the refractory steel of the present invention, the chemical composition of the obtained steel is smelted in a 500kg vacuum induction furnace, and the chemical composition of the obtained steel is shown in the following table, and the balance is Fe and inevitable inclusions. The molten steel is poured into a billet, then the billet is heated to 1150-1250°C and kept for 2 hours, and the steel ingot is rolled above 1000°C into a 60mm intermediate slab. For 20mm thick steel plate, the final rolling temperature is controlled at 820-950°C. Air-cool to room temperature directly after steel rolling, or take rapid water cooling to 450-650°C (cooling rate about 10-30°C / s) and then air-cool to room temperature. The specific process parameters and mechanical properties are shown in the table below. The table also lists the chemical composition, processing technology and corresponding mechanical properties of the aforementioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com