Method for processing outer anticorrosive coating of steel elbow

A processing method and anti-corrosion layer technology, applied to coatings, elbows, pipes, etc., can solve problems such as low production efficiency, achieve the effect of improving production efficiency and avoiding labor and working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

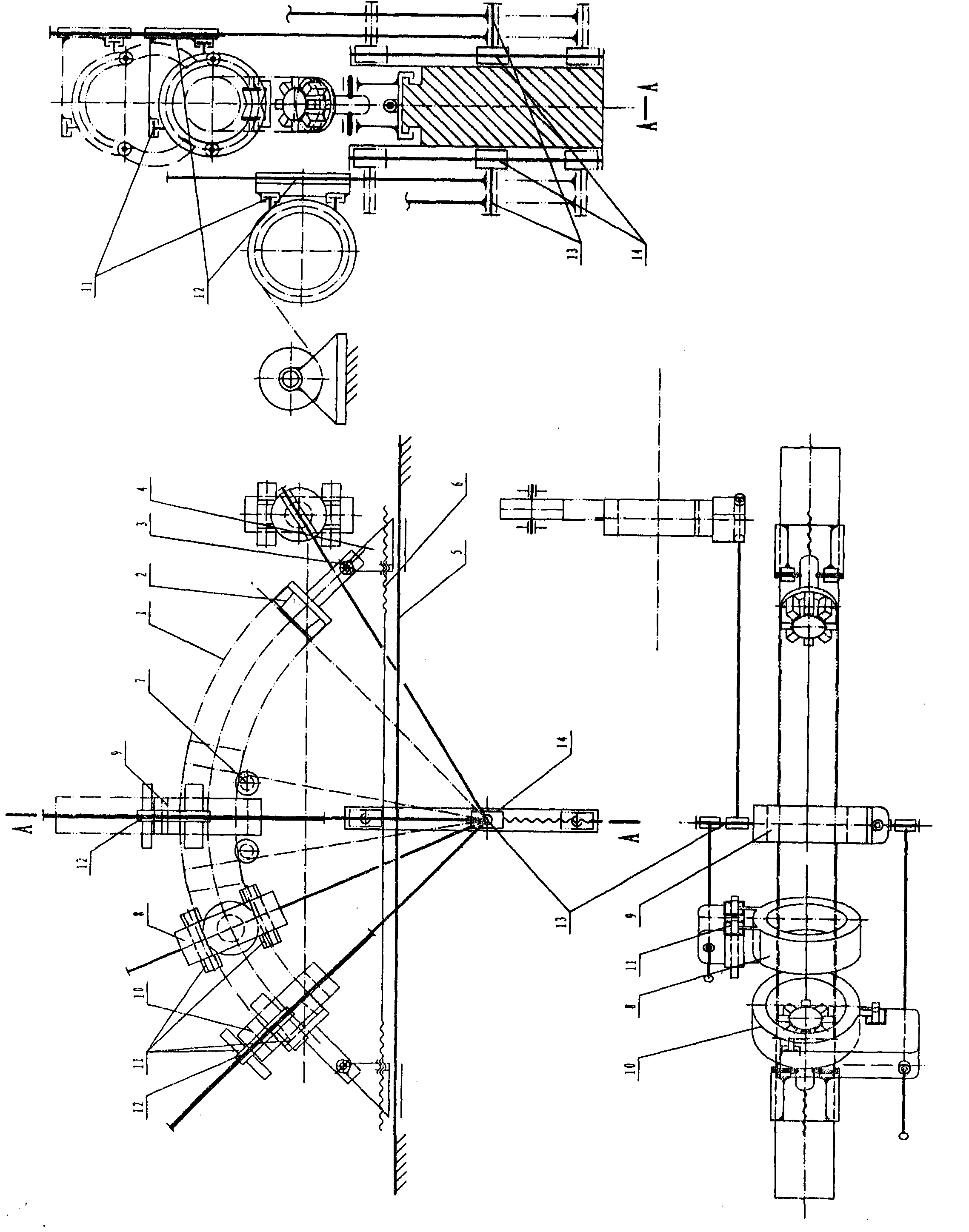

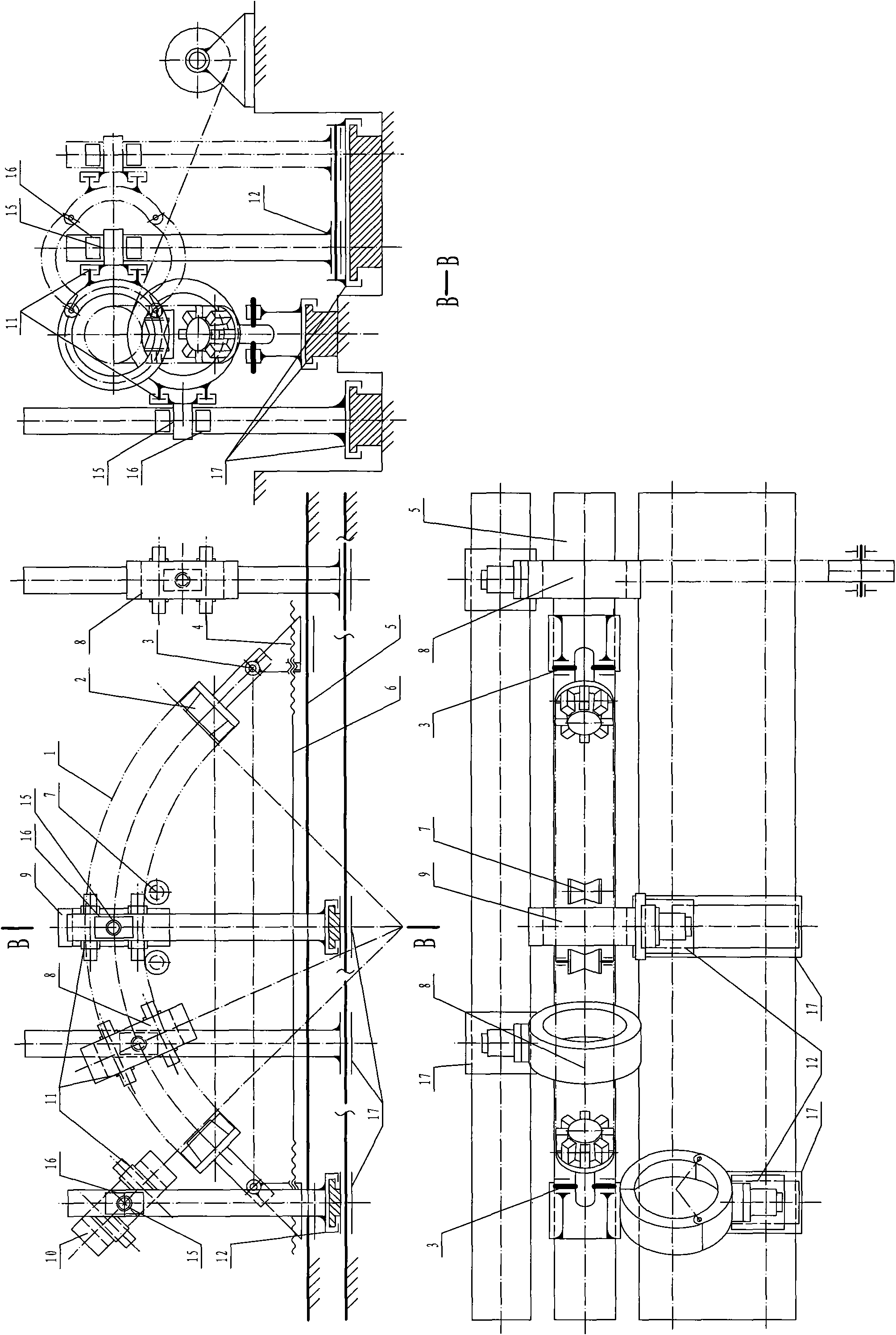

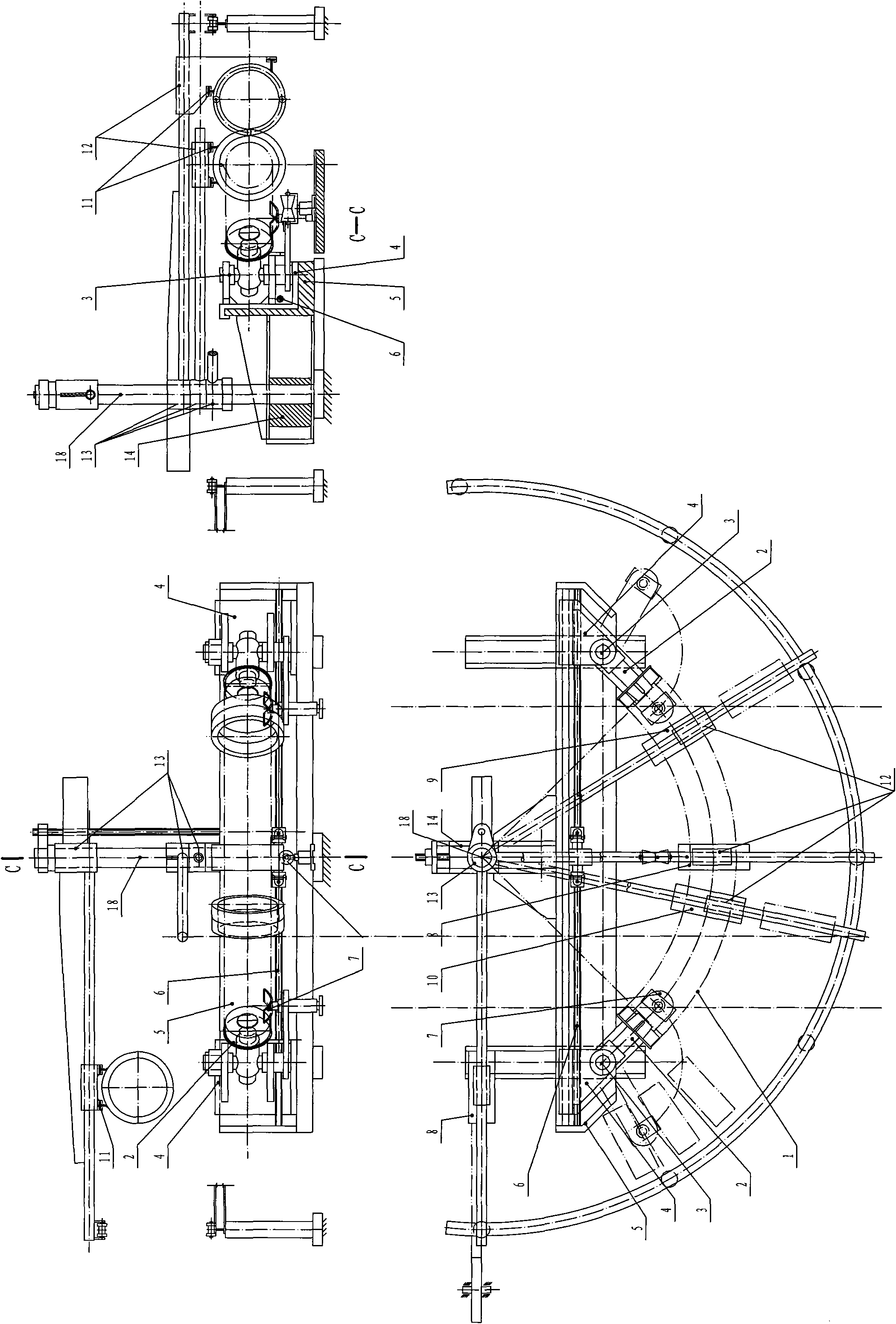

[0020] exist Figure 1 to Figure 4 In the embodiment, the nozzles at both ends of a single elbow (1) are respectively clamped and supported by a set of two nozzle clamps (2), and each nozzle clamp (2) is connected to the shaft (3) installed perpendicular to its axis. The sliding support (4) is hinged and rotatably connected, and the two sliding supports (4) are respectively connected with the pipe bending base (5) along a straight line, and the distance between the two sliding supports (4) is adjusted by the adjustment mechanism (6) Adjust the length. When the elbow (1) is clamped, the clamping position of the elbow (1) is supported and adjusted by N temporary supports (7) below it.

[0021] exist Figure 1 to Figure 4 In the embodiment of the present invention, each forming process component of each anti-corrosion processing process is realized by electric induction heater, electrostatic powder sprayer, winding machine, rolling machine, secondary heater, secondary rolling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com