Light emitting diode (LED) liquid-cooling heat dissipation structure

A heat dissipation structure and liquid cooling technology, applied in cooling/heating devices of lighting devices, lighting and heating equipment, lighting devices, etc., can solve the problems of uncoordinated street light poles, etc. The effect of premature aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

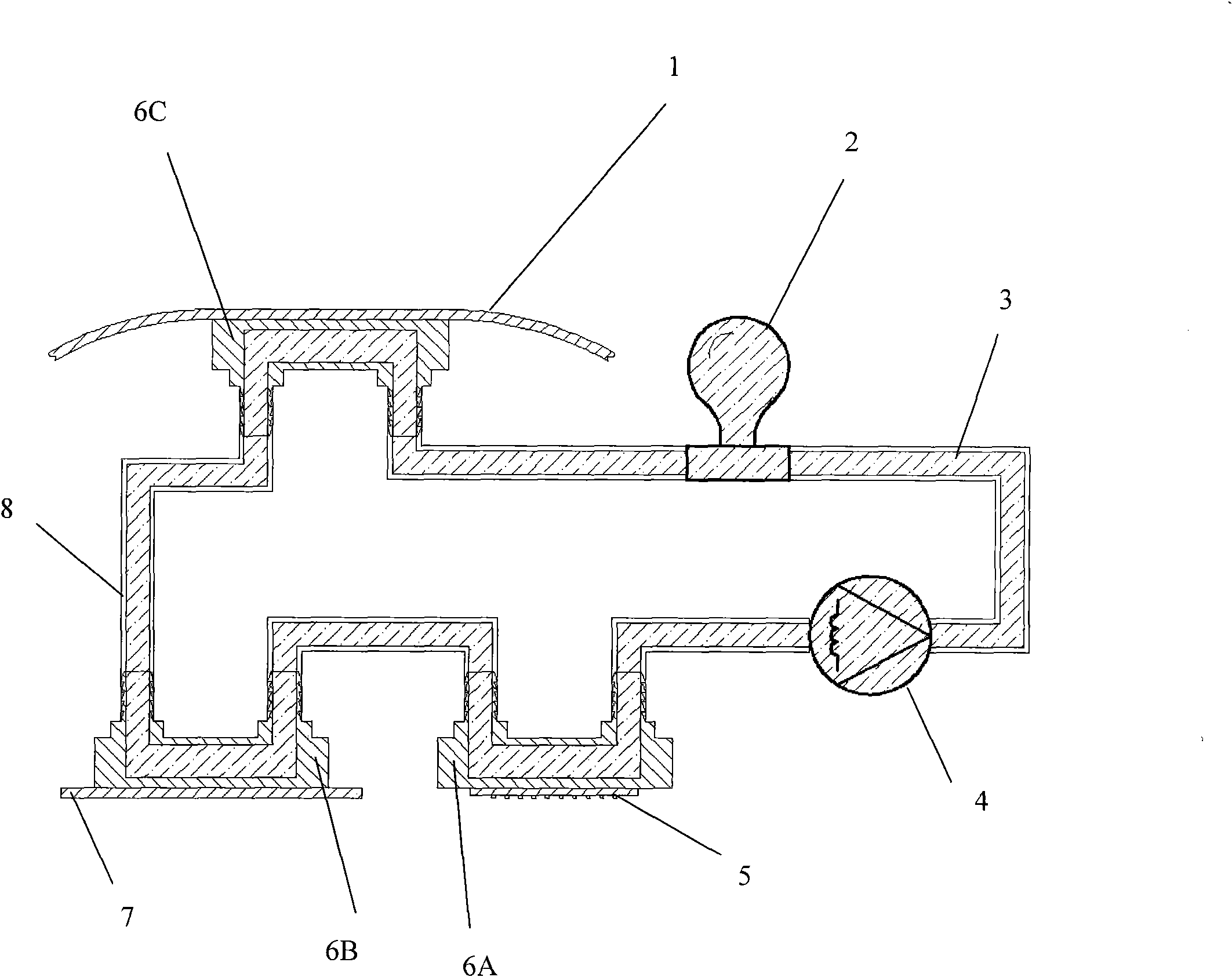

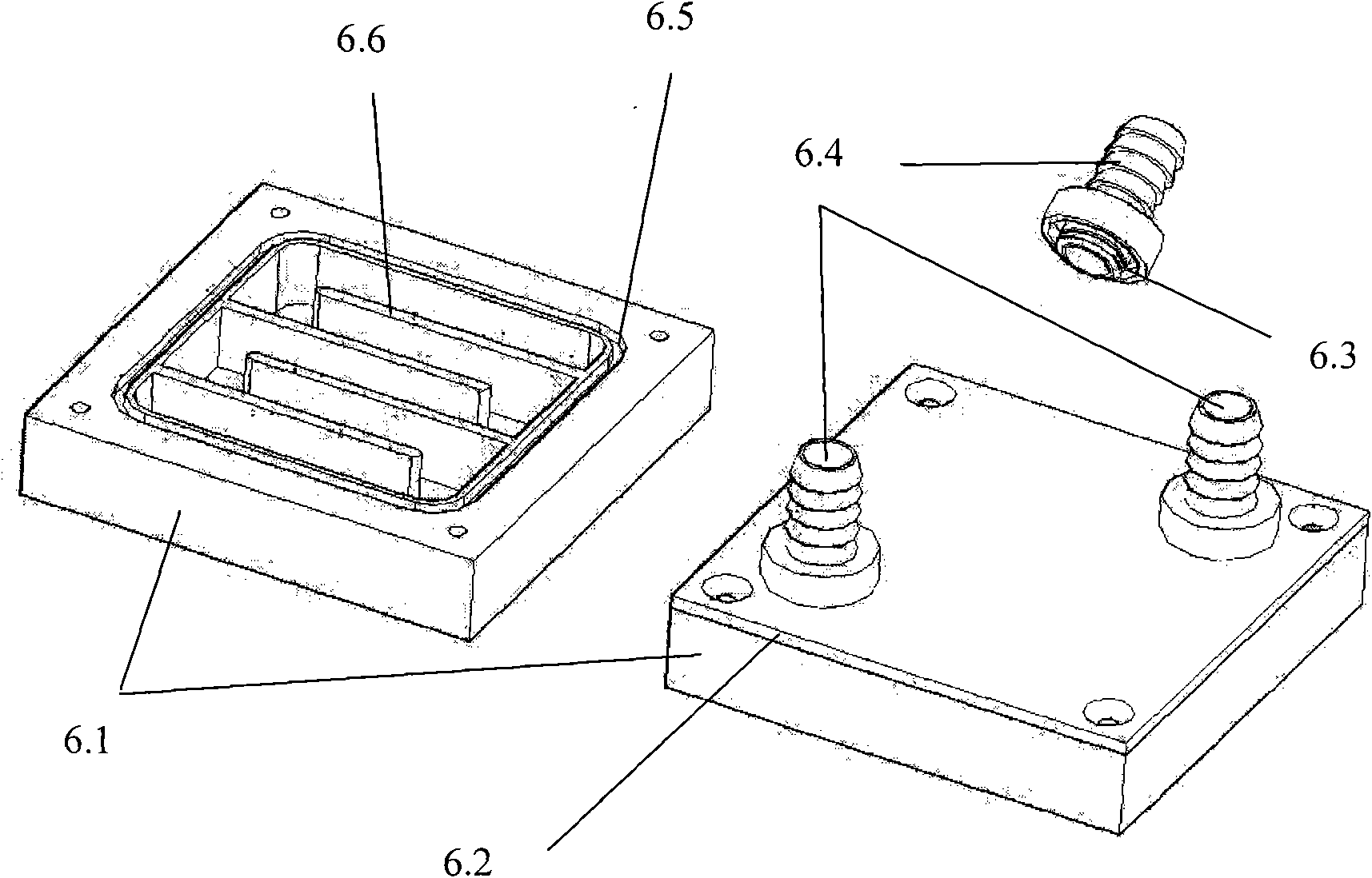

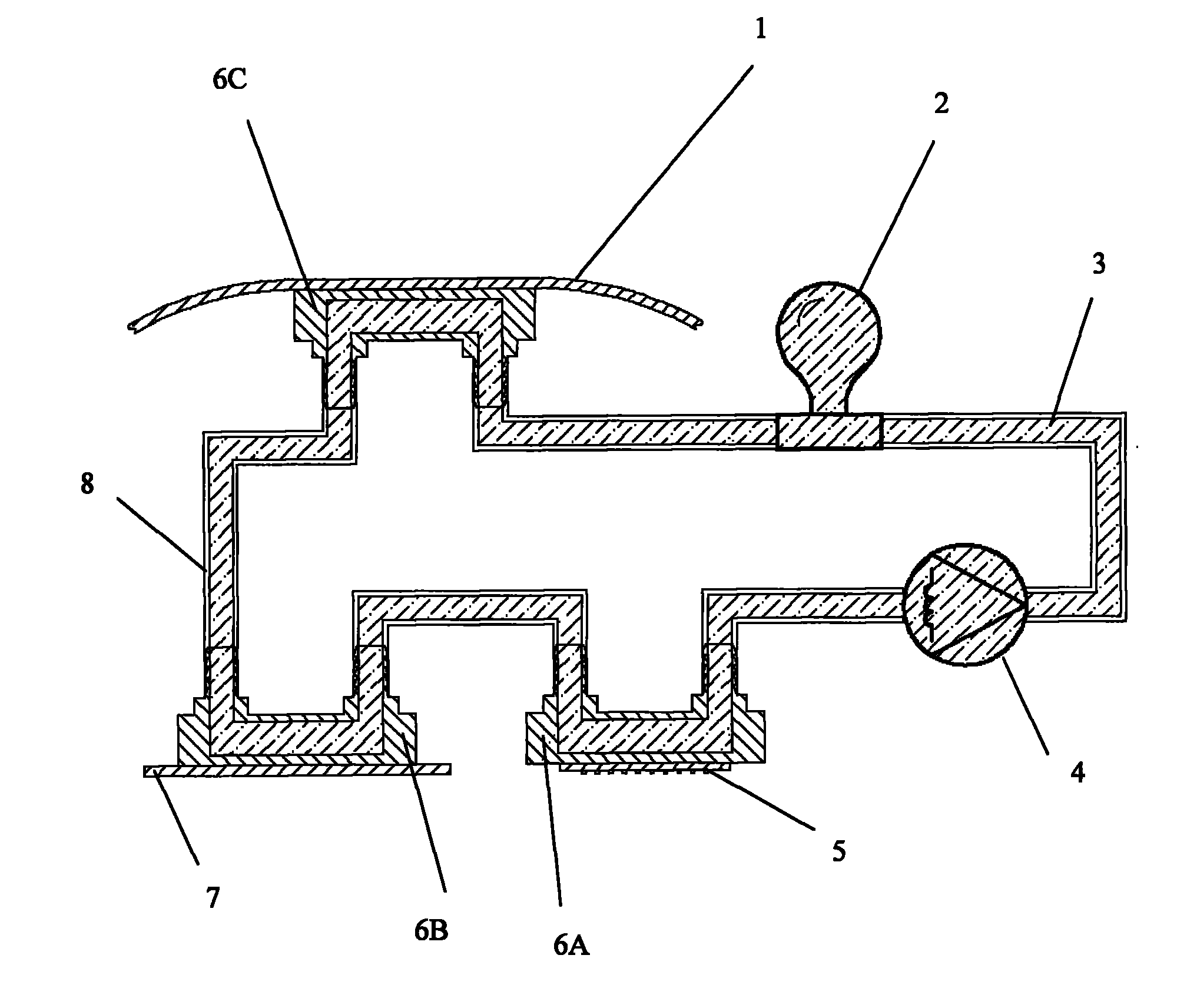

[0027] Best practice:

[0028] The LED liquid-cooled heat dissipation structure is characterized in that: the heat generated by the LED 5 bonded on the aluminum or copper substrate is absorbed and conducted to the liquid heat dissipation medium 3 by the heat exchanger 6A that is closely attached to it, and the pipe 8 communicates with it. With the micro water pump 4, when the water pump is running, the liquid cooling medium 3 is driven to circulate in the expansion buffer 2 and the three heat exchangers 6A, 6B, 6C, and the heat generated by the LED is transferred to the heat exchanger 6B and the heat exchanger 6C In the middle, the shell of the lamp is closely attached to the heat exchanger 6B and the heat exchanger 6C, and the heat in the liquid cooling medium 3 is dissipated into the air by the shell of the lamp; The upper shell part 7 of the lamp is installed in close contact with the heat exchanger 6B.

[0029] At least one miniature water pump 4 is connected in series in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com