Line material mechanical &electrical integration testing machine and dedicated tensile test stand thereof

A tensile test and testing machine technology, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of time-consuming, labor-intensive, uneconomical, inconvenient, etc., and achieve the effect of convenient use and maintenance, simple production and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

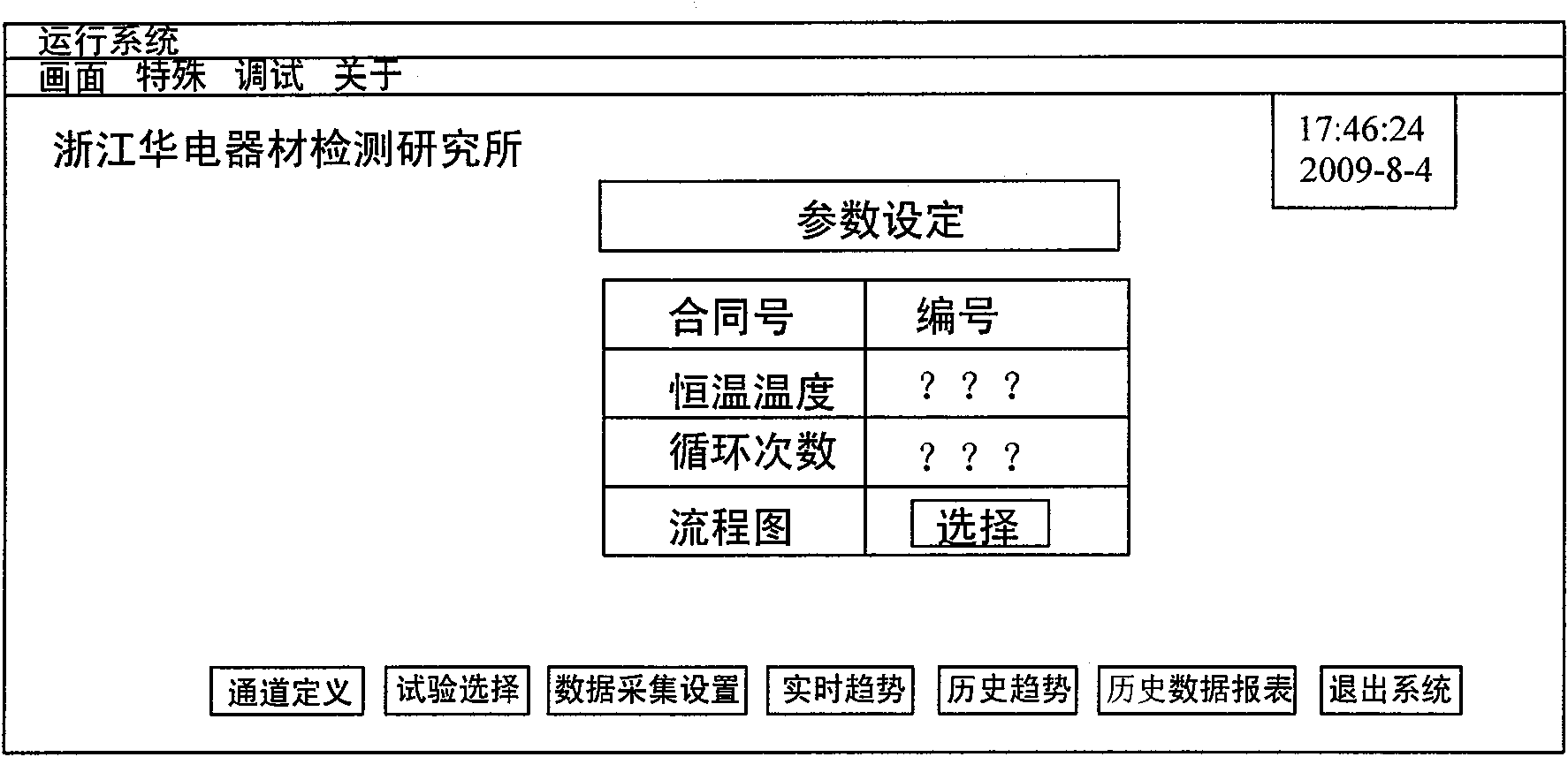

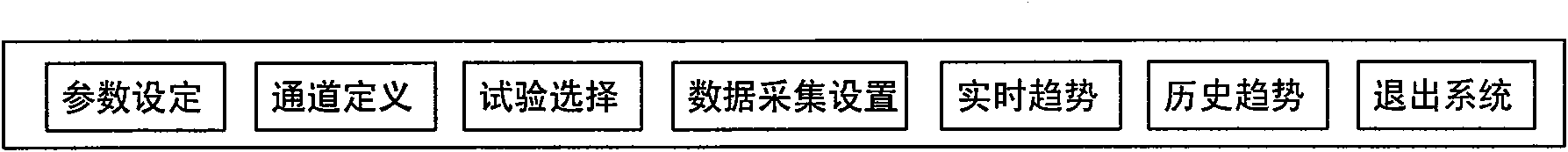

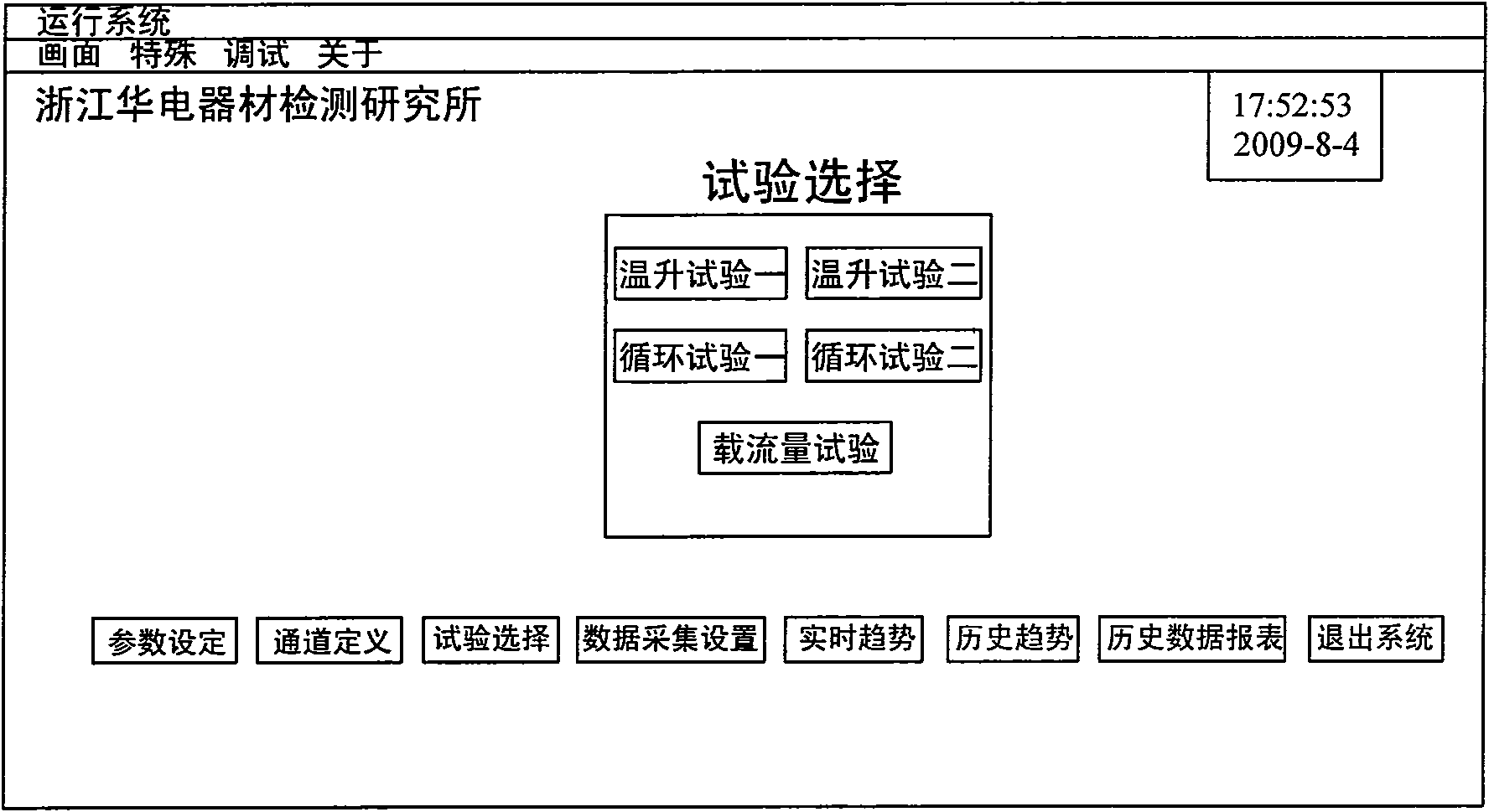

[0030] refer to figure 1 , The electromechanical integrated testing machine for line equipment of the present invention includes a static load tensile testing machine, a current riser 3, a temperature sensor, a multifunctional data acquisition system 10, an electric console 13 and a system power supply box 14. The electric console 13 is connected to the input end of the multifunctional data acquisition system 12, and is used for manually setting various parameters. The system power box 14 provides working power for the multifunctional data acquisition system 12 and the electric console 13 .

[0031] Specifically, the invention includes a mechanical part and an electrical part, the mechanical part is used to load the line equipment with tension and provide tensile test data, and the electrical part is used to load the line equipment with a large current. Combining the functions of the two parts, the invention can carry out some special tests in simulating the actual operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com