Insulation waterproof joint and manufacture method thereof

A waterproof head and processing method technology, applied in the direction of cable joints, cable terminals, etc., can solve the problems of poor aging resistance, poor durability, poor water resistance, etc., and achieve good aging resistance, good durability, and good electrical insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

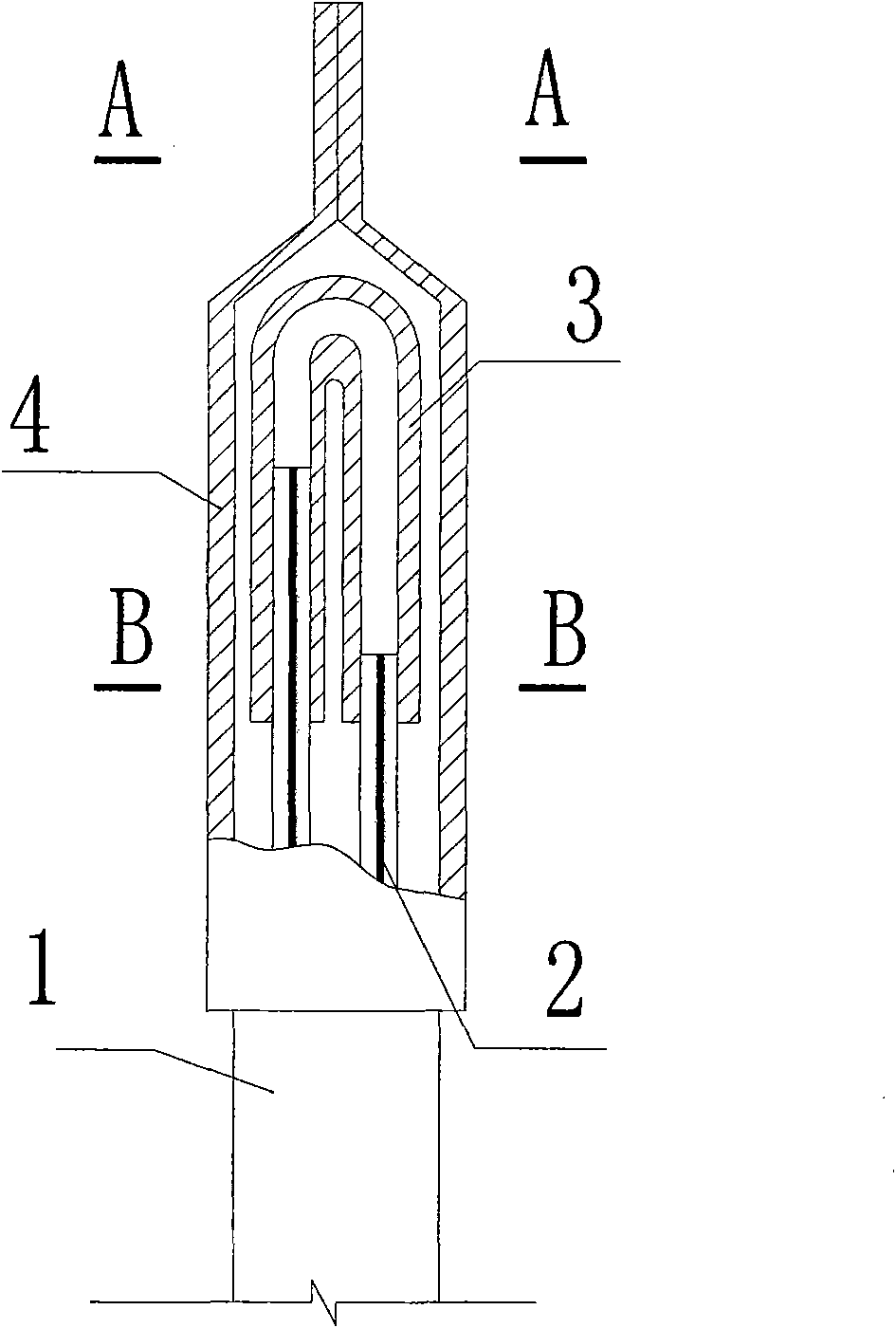

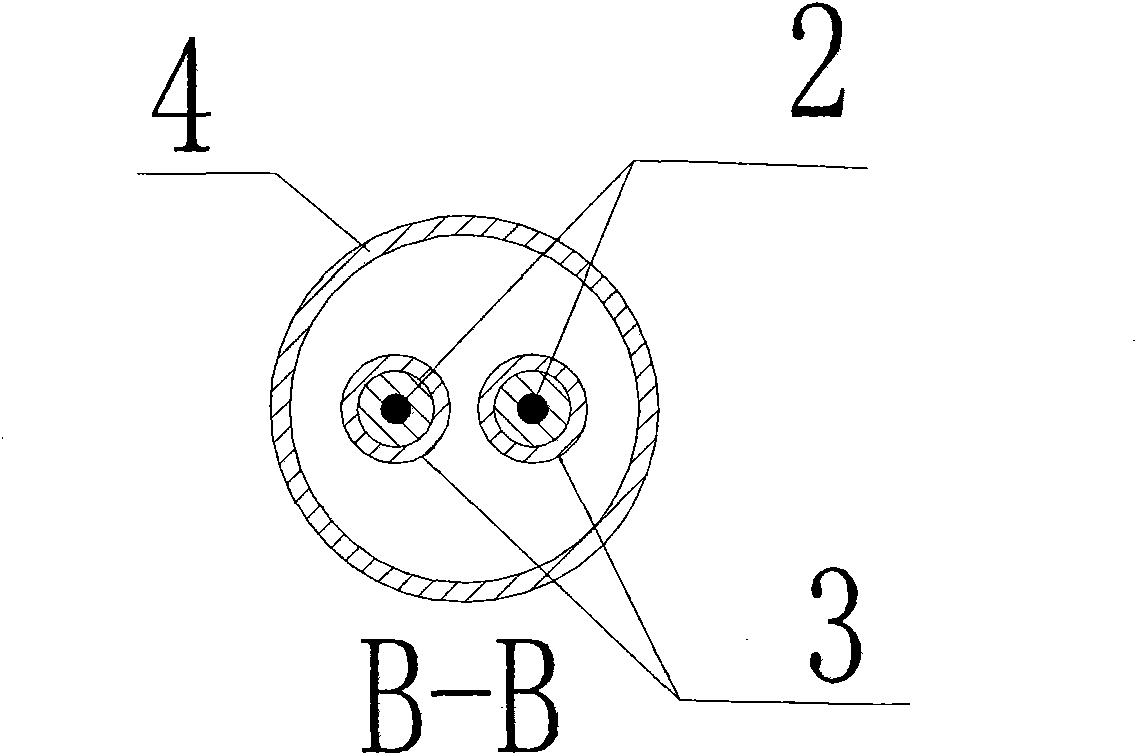

[0022] like Figure 1-3 As shown, the insulating waterproof head includes a cable 1, a first adhesive heat shrinkable tube 3, and a second adhesive heat shrinkable tube 4. The two ends of the heat-shrinkable tube with glue 3 are put on the two wires respectively, the second heat-shrinkable tube with glue 4 is put on the cable at one end, and the other end of the heat-shrinkable tube with glue is crimped with pressure clamps, and the crimping length is 10mm-30mm, the diameter of the first heat-shrinkable tube 3 with glue is d=4mm, and the diameter of the second heat-shrinkable tube 4 with glue is d=10mm.

[0023] The production method is as follows: the end of the cable 1 with the insulated waterproof head is stripped off the two flexible wires 2 at the remaining free end of the end sheath; The difference in cutting length is 5 mm to 10 mm; put the two ends of the first glued heat-shrinkable tube 3 (d=4mm) into the two wires 2, and use a heat gun to heat seal the first glued h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com