Devices and method for detecting the condition of an edge of a work piece

A technology for measuring positions and workpieces, which is applied to metal processing machinery parts, manufacturing tools, metal processing, etc., can solve the problems of inaccuracy and inappropriateness, and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

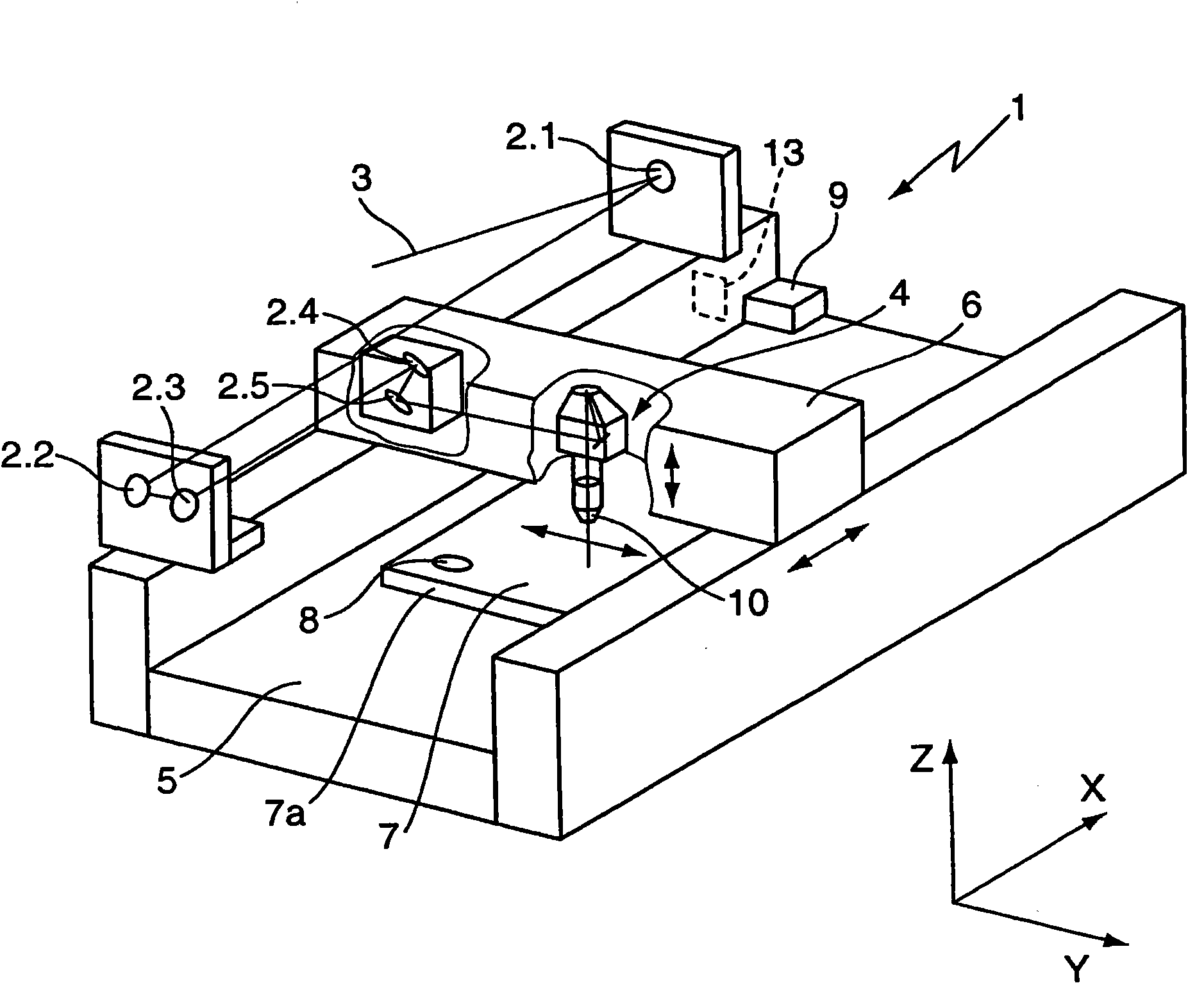

[0028] figure 1 A machine tool 1 for laser machining is shown, which has a beam-guiding optics with a plurality of optical elements 2.1 to 2.5 for guiding a laser beam 3 to a laser machining head 4 on. In order to move the laser processing head 4 along a processing table defining the working plane 5 in the first spatial direction X of the XYZ coordinate system, the laser processing head 4 is fixed on a carriage that can travel in the first spatial direction X 6, as indicated by the double arrow. The laser processing head 4 can also travel in the working plane 5 in the second spatial direction Y by moving the laser processing head 4 along the carriage 6 , as also indicated by the double arrow. In this way, the laser machining head 4 can be moved in the two spatial directions X, Y over the entire working plane 5 of the machining table and in this case process the workpiece 7 positioned on the machining table. In addition, the laser processing head 4 can also be moved relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com