Technique and device for dry dedusting of wet dust-laden gas

A dry dust removal and wet dust technology, applied in the direction of removing smoke and dust, separation methods, chemical instruments and methods, etc., can solve problems such as sticking filter bags, blocking dust removal pipes, etc., and achieves low initial investment and operating costs, and strict emission standards. , the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

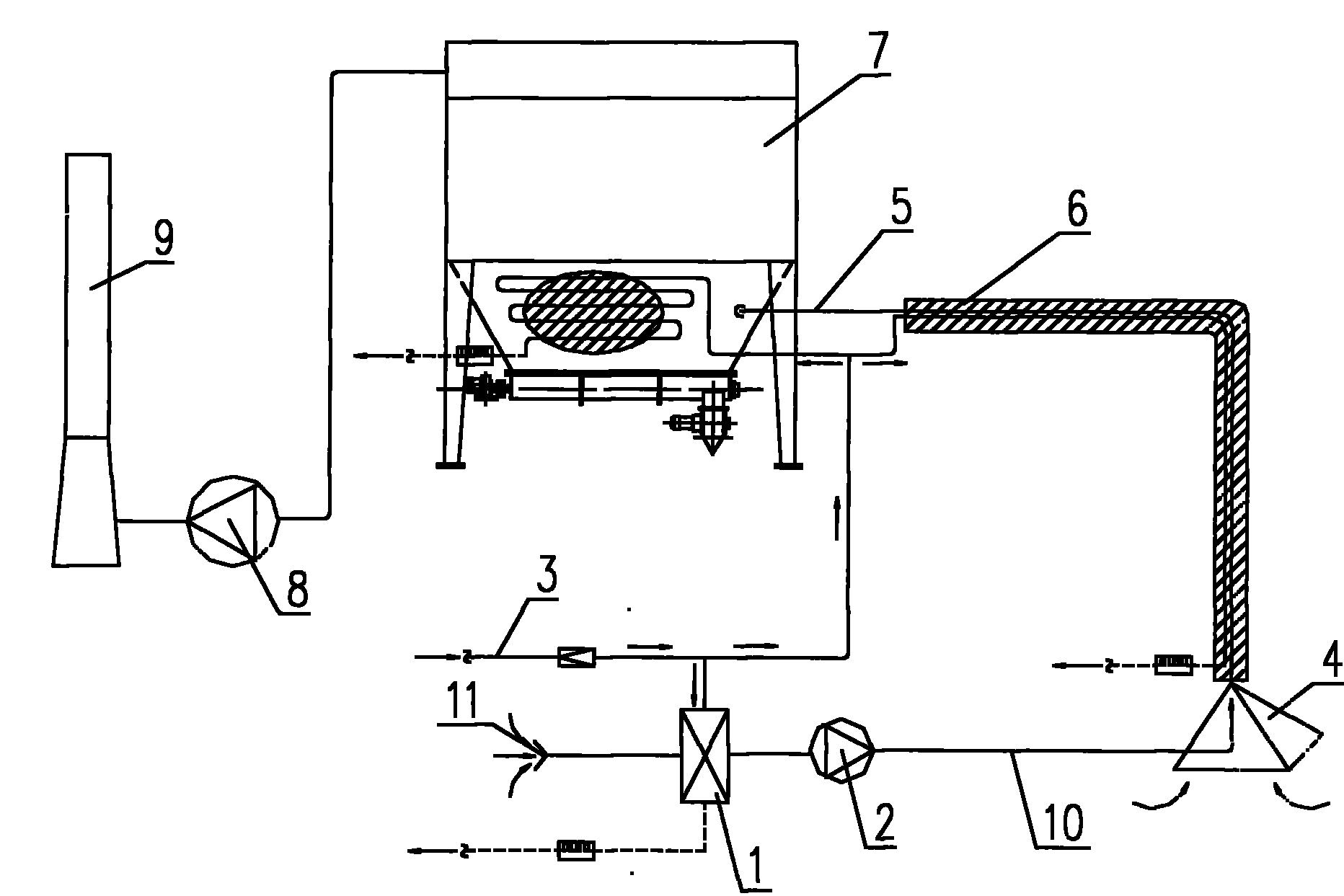

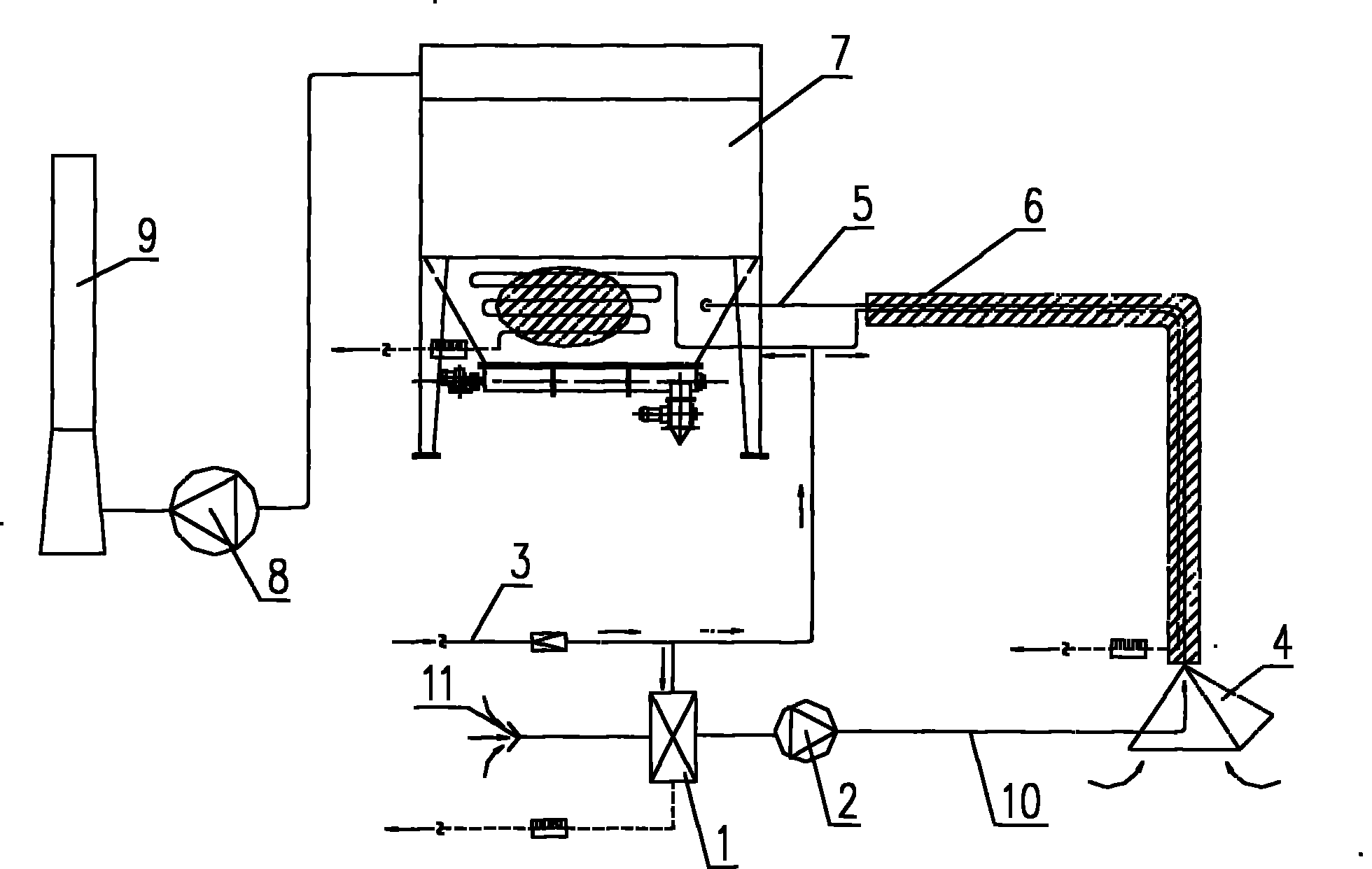

[0023] The following is a specific example of dust removal at a single-belt wet quenching transfer station in a coking plant, described as follows:

[0024] known conditions:

[0025] 1 focal belt machine head at the transfer station, 2500m 3 / h (Temperature of dust in the suction hood is 50°C, measured value)

[0026] 1 feeding point of the coke belt machine at the transfer station, 3500m 3 / h (Temperature of dust in the suction hood is 50°C, measured value)

[0027] The wind speed at the mouth of the suction hood is 0.6~1m / s

[0028] The mass density of coke dust particles is 0.45~0.5t / m 3

[0029] The dust gas in the suction hood is saturated humid air at a temperature of 50°C, and its density ρ b =1.043kg / m 3 , moisture content d b =86.2g / kg dry air (d b =82.3g / m 3 Humid air), water vapor partial pressure P q.b =123.04(mbar)

[0030] The dust concentration of the dust gas in the suction hood is 2~3g / m 3

[0031] The average equivalent diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com