On-line calculation method for desulfurization efficiency of circulating fluidized bed boiler

A circulating fluidized bed and desulfurization efficiency technology, applied in the field of electric power, can solve problems such as online calculation of circulating fluidized bed boiler desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

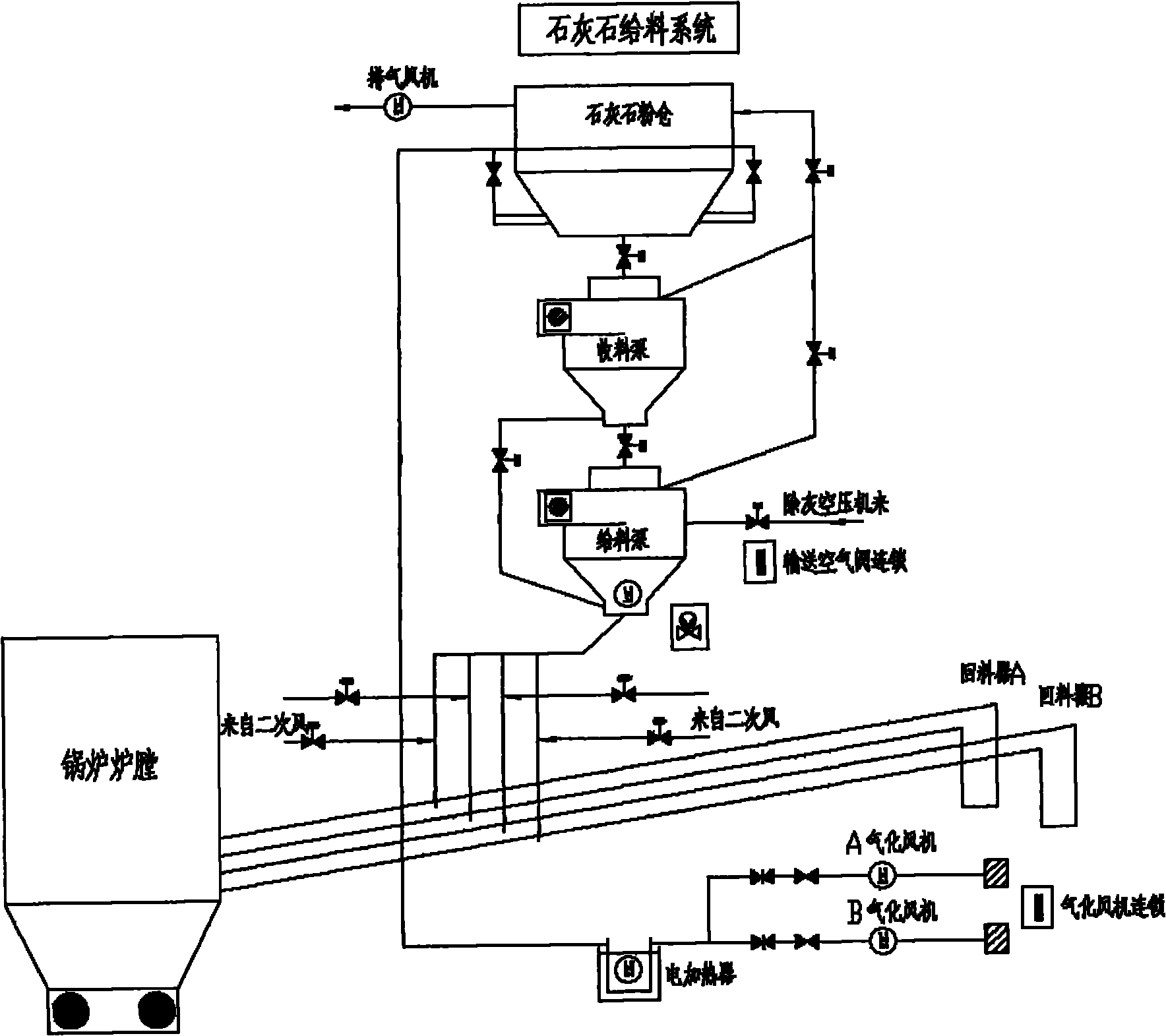

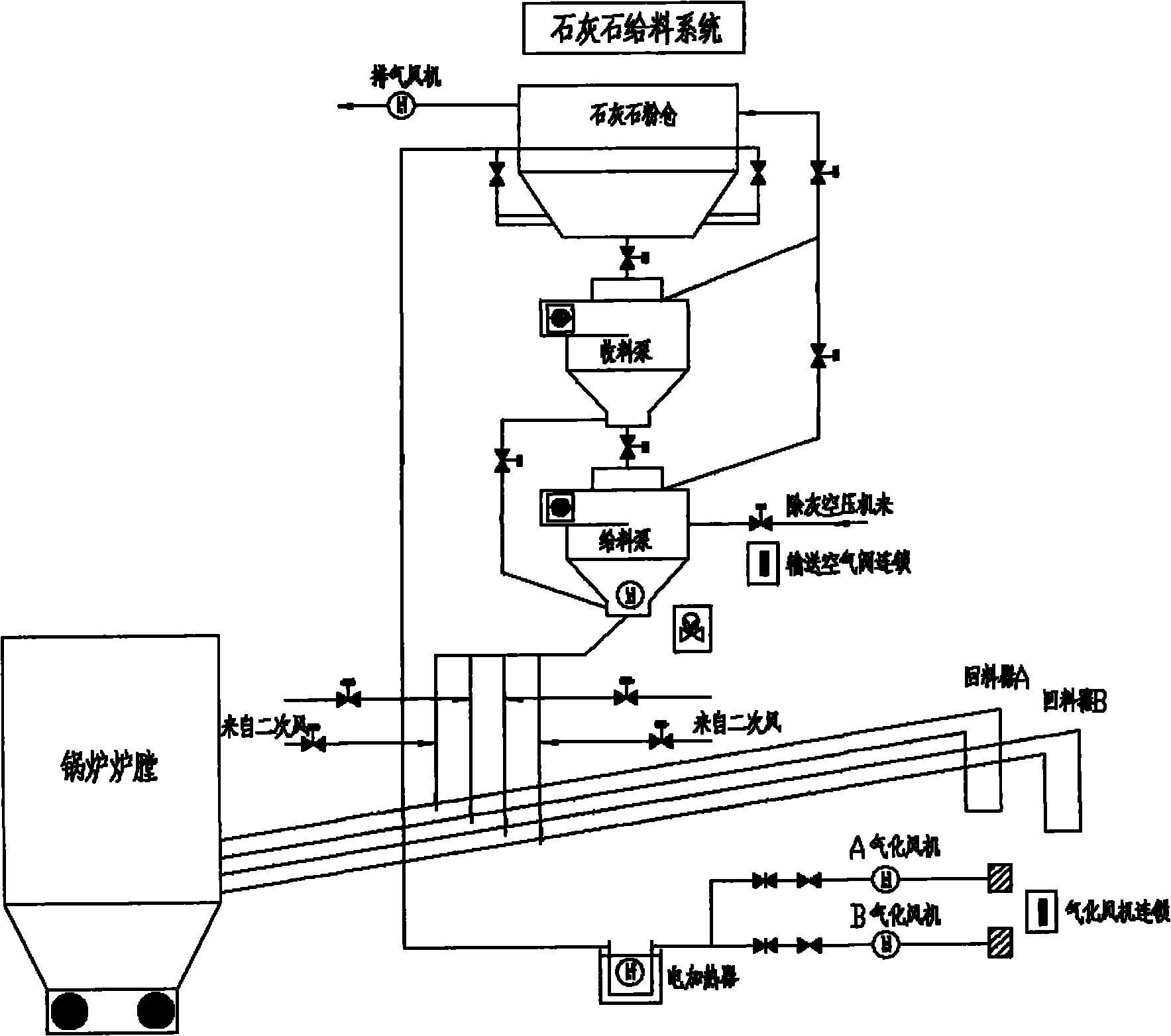

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

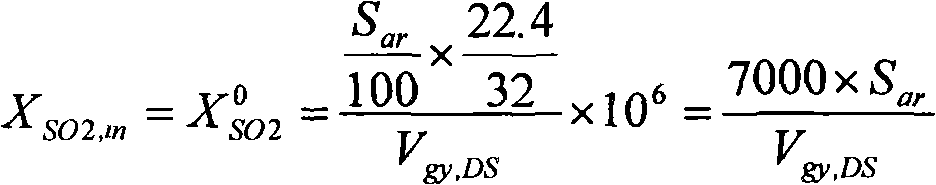

[0046] 1) Calculation of original emission concentration

[0047] Since the CFB boiler adopts in-furnace desulfurization, there is no imported SO 2 Measuring point. Due to the low-temperature combustion characteristics of CFB boilers, the degree of self-desulfurization of coal is also greater than that of pulverized coal boilers. There are many factors affecting the self-desulfurization efficiency of coal. The self-desulfurization efficiency of CFB boilers is 10-40% or more. At present, there is no reliable calculation formula and data, and it is generally determined through experiments for specific coal types.

[0048] Therefore, it is recommended that the entire CFB boiler unit be used as desulfurization equipment, using SO 2 The theoretical production concentration is used as the inlet emission concentration of the CFB boiler, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com