Automatic butt welding equipment for metal sheet

An automatic welding and metal sheet technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult welding, inapplicability, and inability to weld, and achieve the effect of ensuring quality, efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

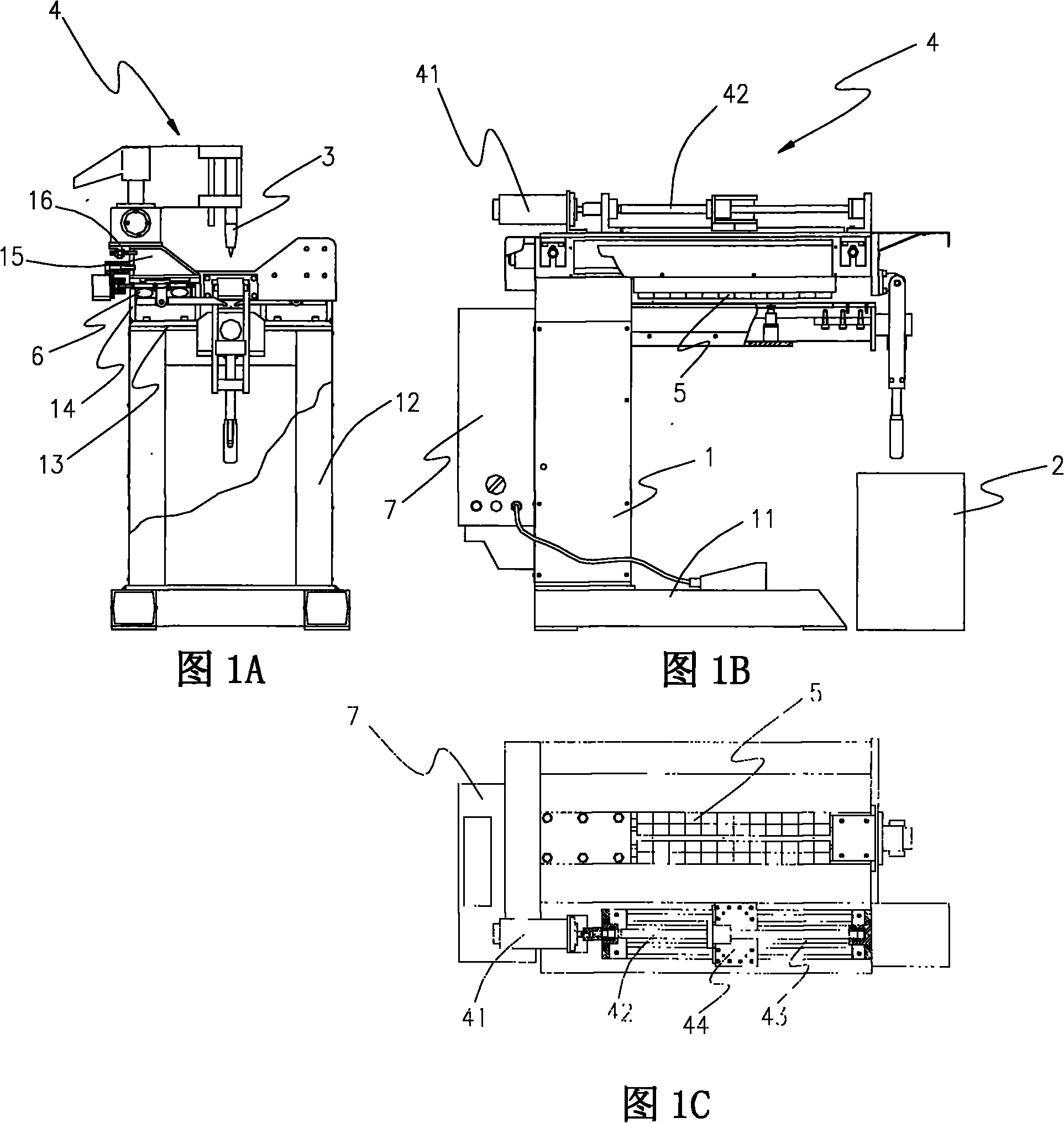

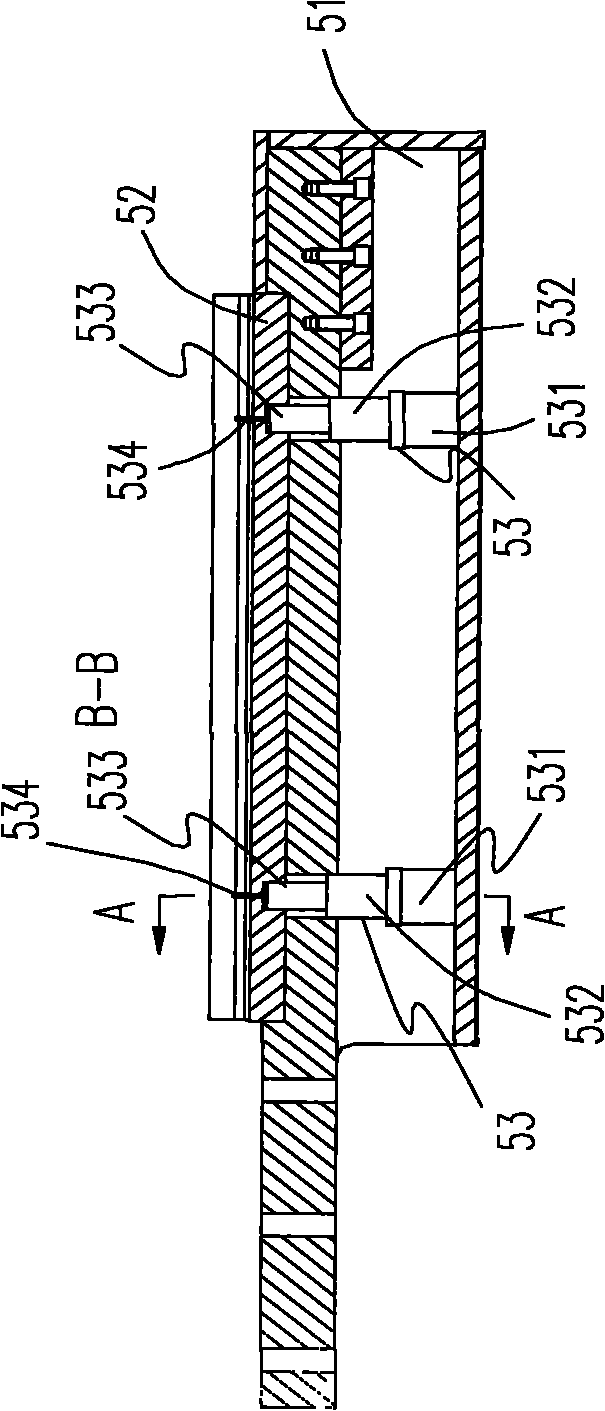

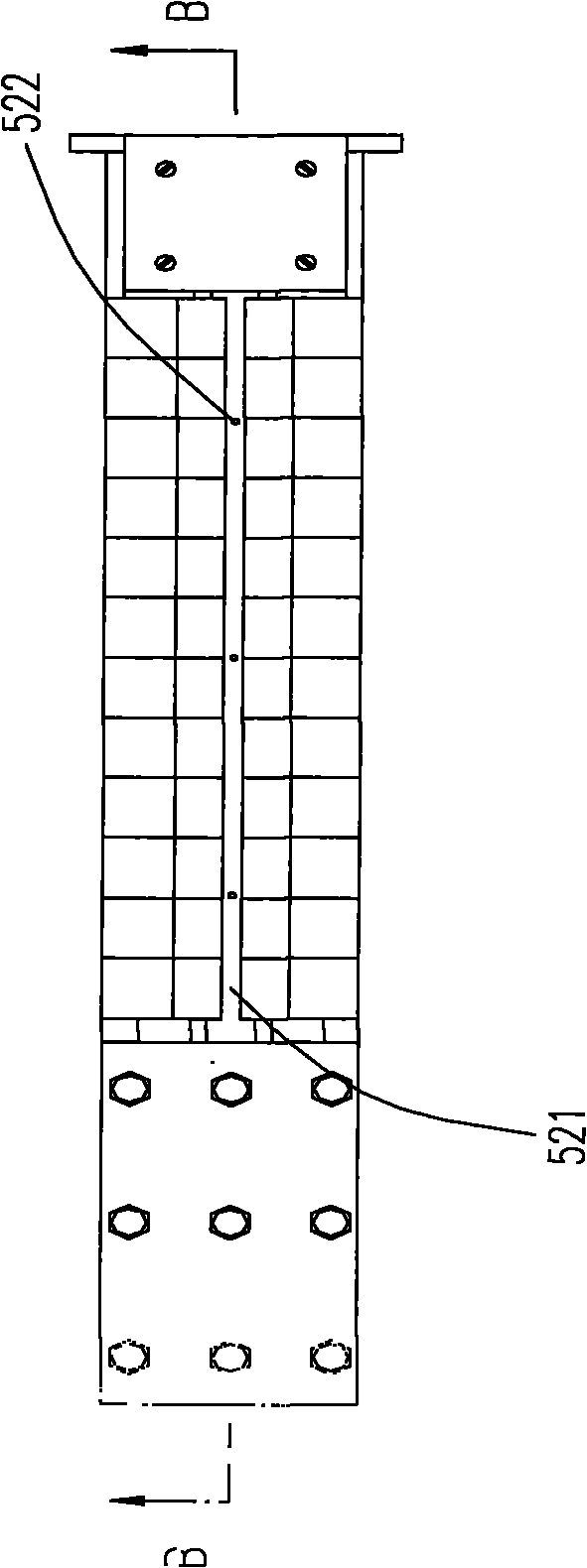

[0024] Figures 1A-1B Shown is a specific embodiment of the automatic butt welding equipment for thin metal plates according to the present invention. The design and manufacture are guided by a special welding process for butt welding of stainless steel longitudinal seams with a thickness of 0.1 mm, and argon tungsten arc welding is used. Do the welding. In the embodiment shown in the figure, the metal sheet butt automatic welding equipment is mainly composed of a frame 1, a welding machine 2, a welding torch 3, a welding torch driving mechanism 4, a workpiece centering mechanism 5, a workpiece clamping mechanism 6, an electric control Box 7, and laser guidance instrument (not shown in the figure) etc. are formed. Its specific structure is as follows:

[0025] The frame 1 mainly includes a base 11 , a bracket 12 erected on the base 11 , a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com