Flat steel positioning device

A positioning device and flat steel technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low production efficiency, difficult to control welding quality, poor production site environment, etc., and achieve easy operation and positioning Accurate and convenient, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

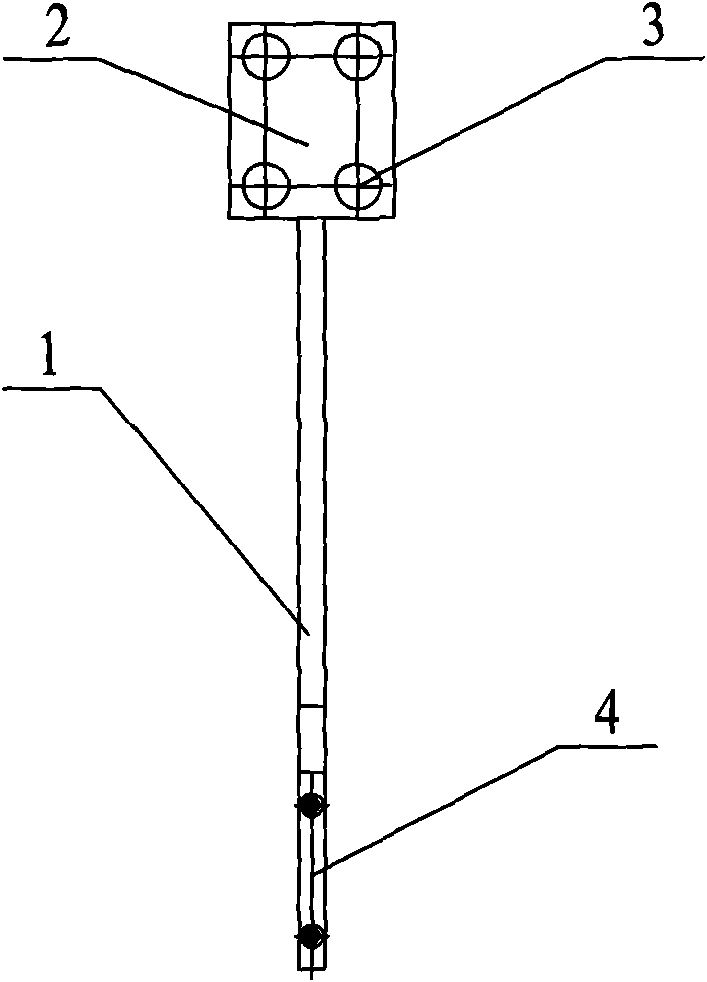

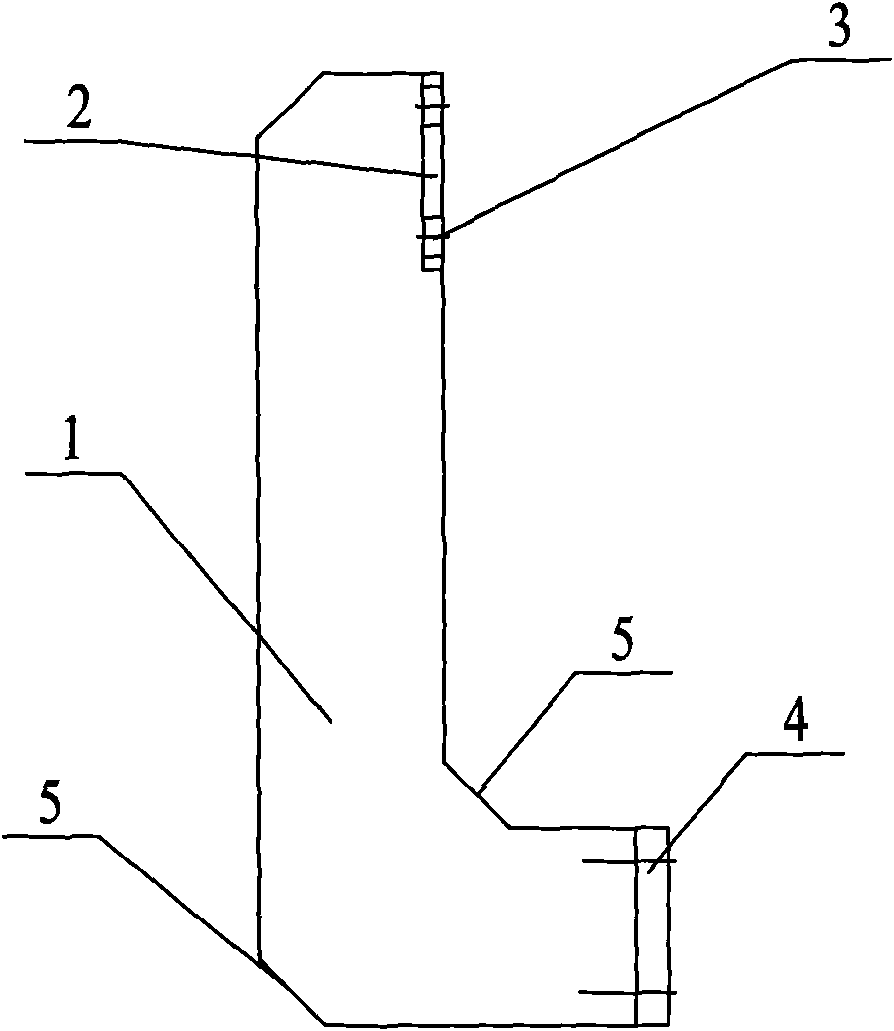

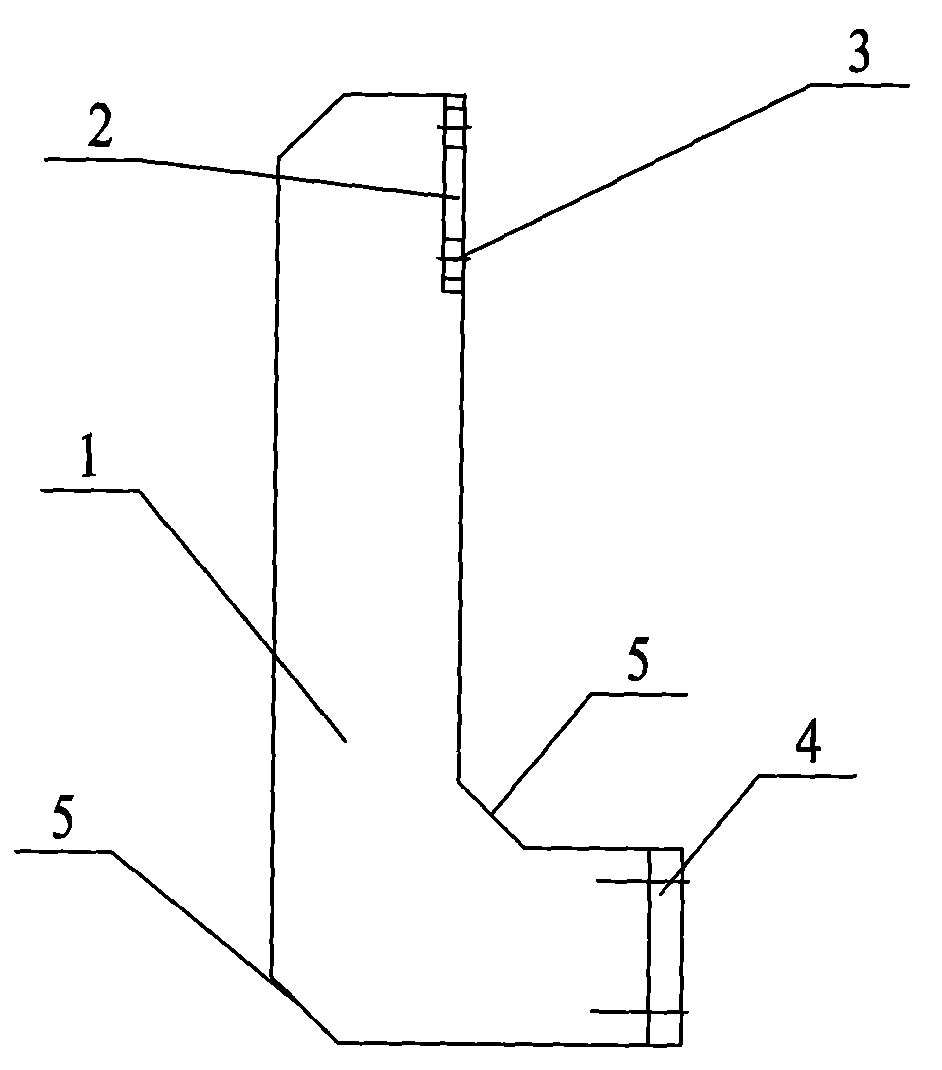

[0013] Such as figure 1 As shown, the flat steel positioning device of the present invention is mainly made up of L-shaped positioning bracket 1 and magnet 4, and the upper end of L-shaped positioning bracket 1 is provided with mounting base 2, and mounting base 2 is used for connecting machine base; The plane is perpendicular to the plane of the L-shaped positioning bracket 1, and four bolt holes 3 are provided on the mounting base 2, and the L-shaped positioning bracket 1 is fixed on the machine base with bolts; The hexagonal screw installs the magnet 4, and the magnet 4 is used to hold the flat steel positioning; for the convenience of loading and taking off the workpiece, the magnet 4 preferably adopts an electromagnet, so that when the workpiece needs to be loaded into and taken off, the electromagnet is cut off. Easy to operate with power.

[0014] Such...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap