Processing process for compressing and riveting nuts

A processing technology and a technology for pressing riveting nuts, which are applied in the field of processing technology of pressing riveting nuts, can solve the problems of seriousness, low strength and low production efficiency, and achieve the effects of dense internal structure, good tensile strength and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

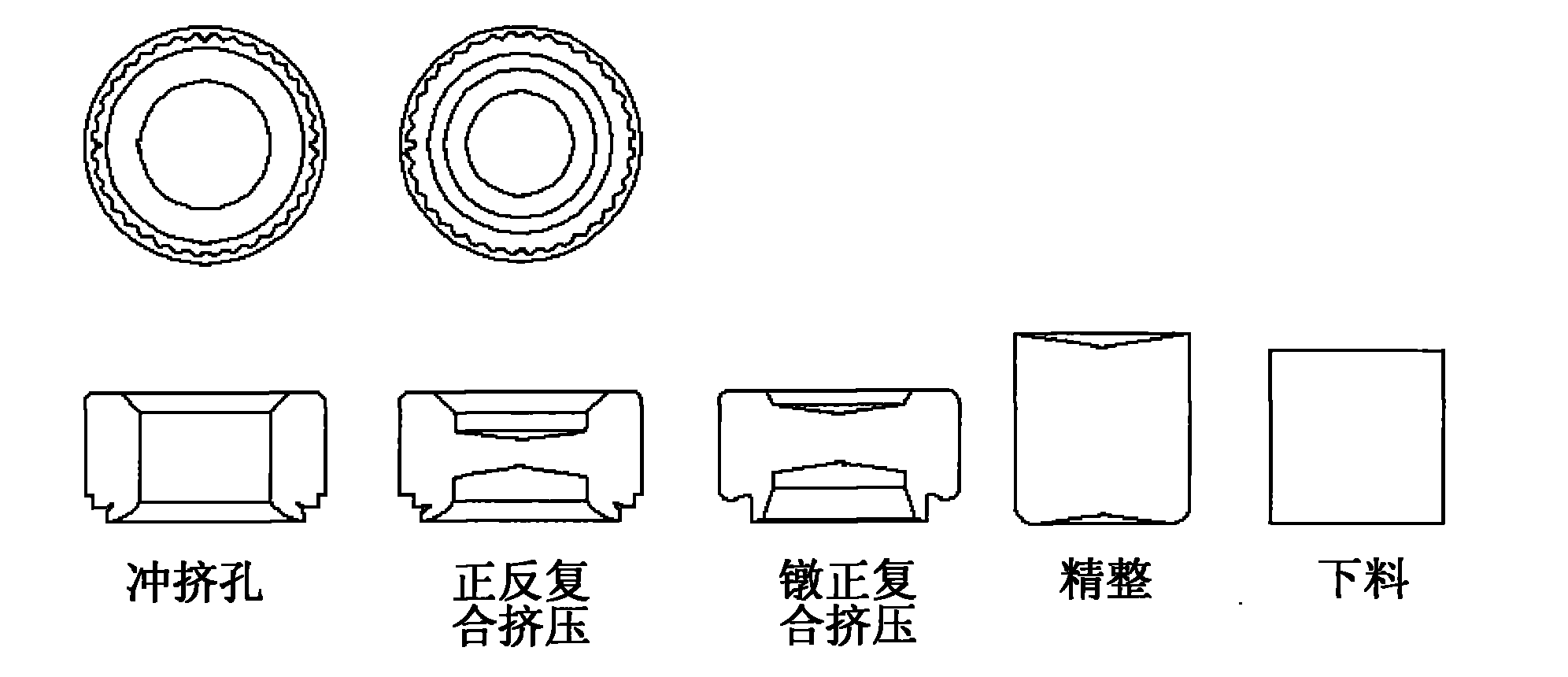

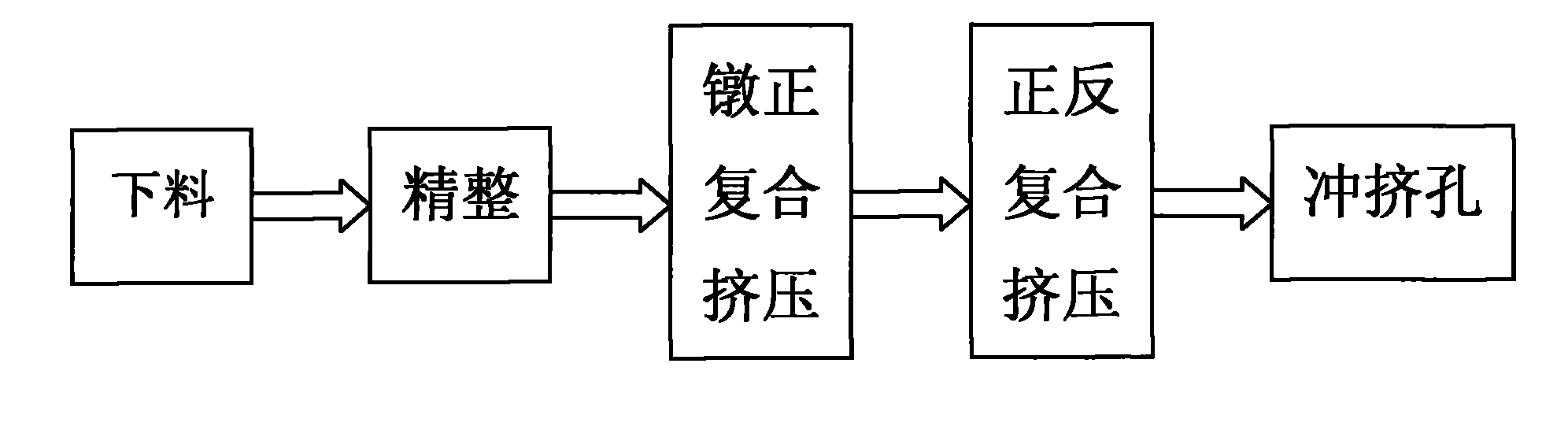

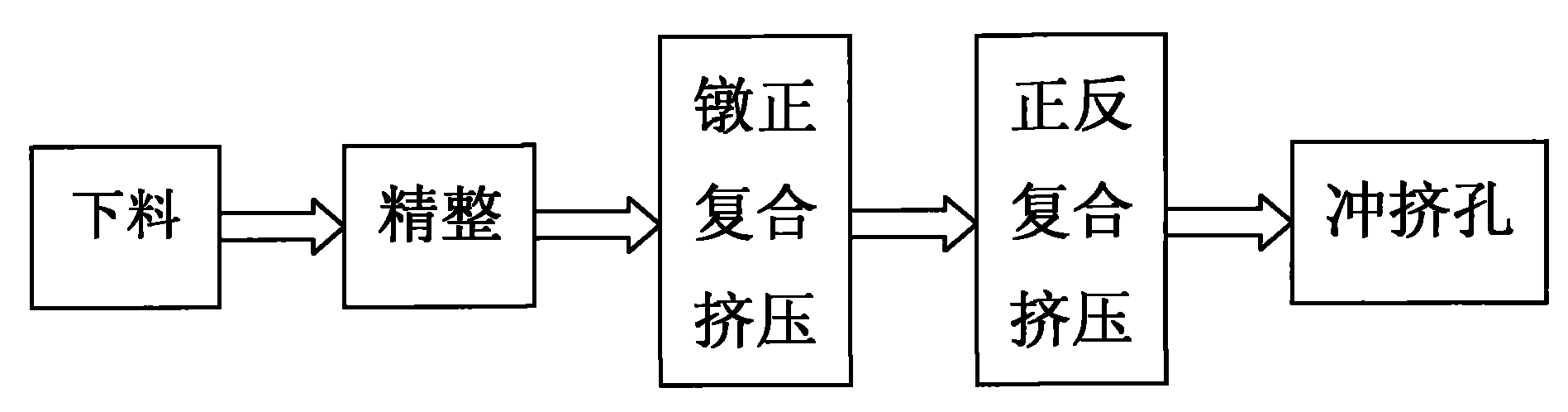

[0011] A processing technology for pressure riveting nuts. Firstly, the raw material is blanked, and then the billet is cold-finished, and then the head is upset and compound-extruded, and then the front and back are compound-extruded, the spline and the lower mouth, and finally punched and extruded Hole, tap the inner hole. The raw material is a wire rod that has been spheroidized and annealed, and the surface has been lubricated. In order to easily form the hole when punching and extruding the hole, a small circular hole is back-extruded at the upper end during the above-mentioned forward and reverse compound extrusion.

[0012] combine figure 1 and figure 2 Take the M8-1 rivet nut as an example:

[0013] The product performance requirements are: pushing force ≥ 1871N, torque force ≥ 18.7N·M

[0014] Firstly, according to the three-dimensional simulation analysis software, the cold forging process, design mold making and material preparation are simulated, which saves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com