Planet carrier and processing technology thereof

A processing technology and planet carrier technology, which is applied in the directions of transmission parts, components with teeth, belts/chains/gears, etc. Simple, high machining accuracy and easy machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

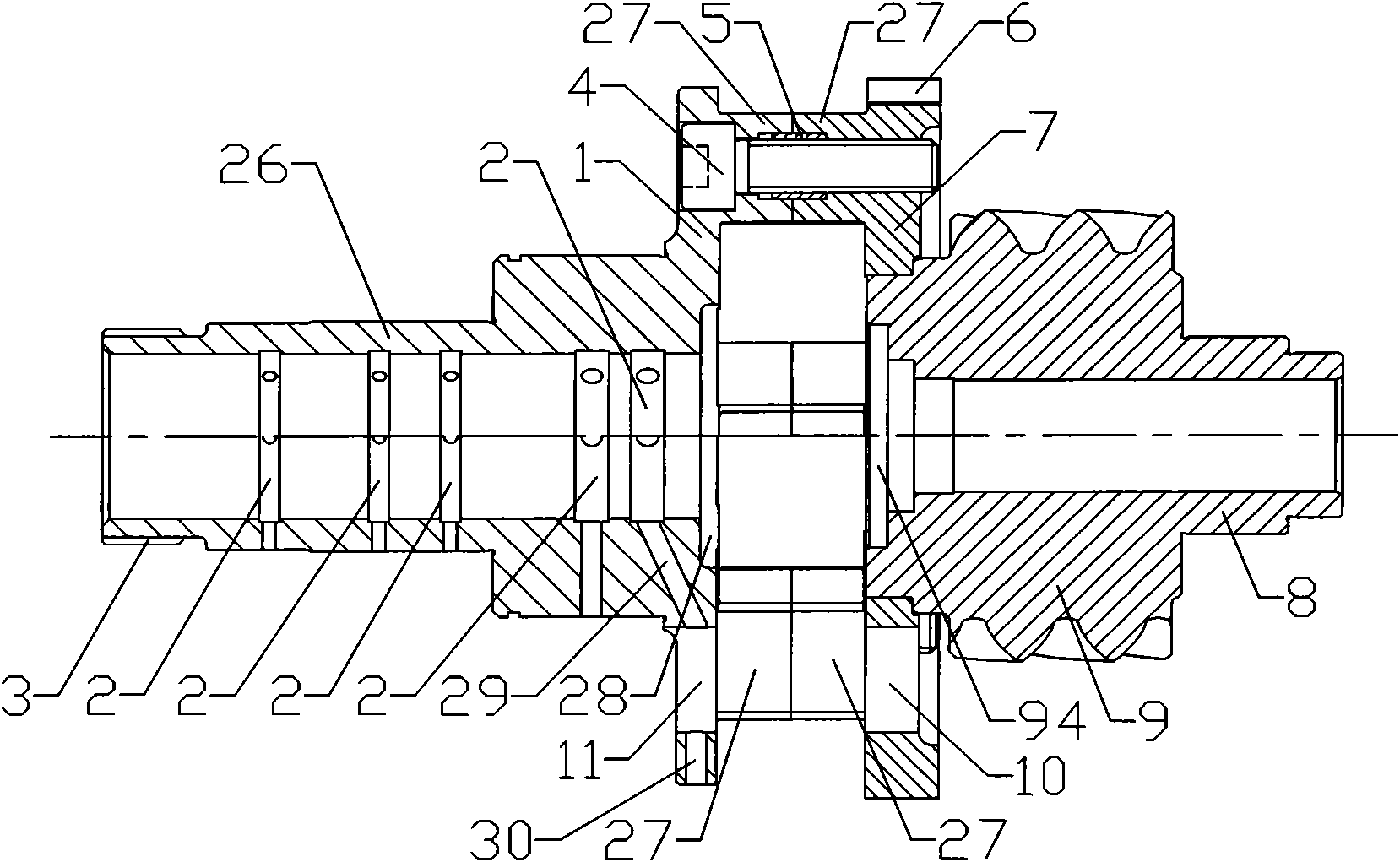

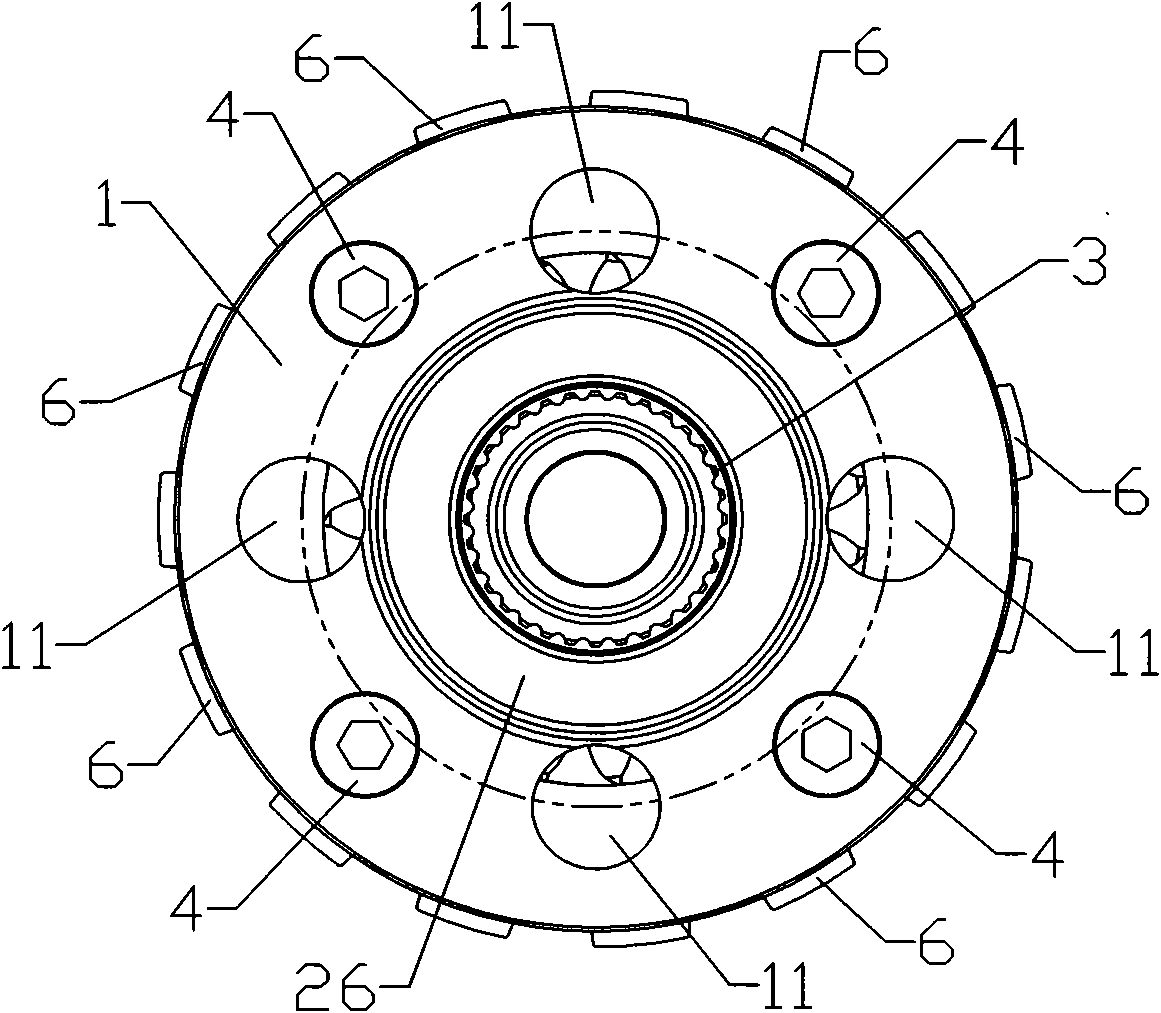

[0088] Embodiment 1: as attached figure 1 , attached figure 2 And attached image 3 As shown, a planetary carrier includes a planetary carrier body. The planetary carrier body includes two planetary carrier members. The two planetary carrier members are independent individuals. The two planetary carrier members are connected to form the planetary carrier body. The two planetary carrier members The connection method is a detachable connection, and the connection method of the two planetary frame members is a bolt connection.

[0089] The two planetary carrier members are the first planetary carrier member 1 and the second planetary carrier member 7, the first planetary carrier member 1 is a planetary carrier member provided with a sleeve support portion 26, and the second planetary carrier member 7 is connected to the gear 9 The first planetary carrier member 1 is provided with a groove 28 on the inner end surface, and the number of bolts 4 is four, and the four bolts 4 are ...

Embodiment 2

[0115] Embodiment 2: as attached Figure 4 As shown, a planetary carrier includes a planetary carrier body. The planetary carrier body includes two planetary carrier members. The two planetary carrier members are independent individuals. The two planetary carrier members are connected to form the planetary carrier body. The two planetary carrier members The connection method is a detachable connection, and the connection method of the two planetary frame members is a bolt connection.

[0116]The two planetary carrier members are the first planetary carrier member 1 and the second planetary carrier member 7, the first planetary carrier member 1 is a planetary carrier member provided with a sleeve support portion 26, and the second planetary carrier member 7 is connected to the gear 9 The first planetary carrier member 1 is provided with a groove 28 on the inner end surface, and the number of bolts 4 is four, and the four bolts 4 are evenly distributed along the circumferential ...

Embodiment 3

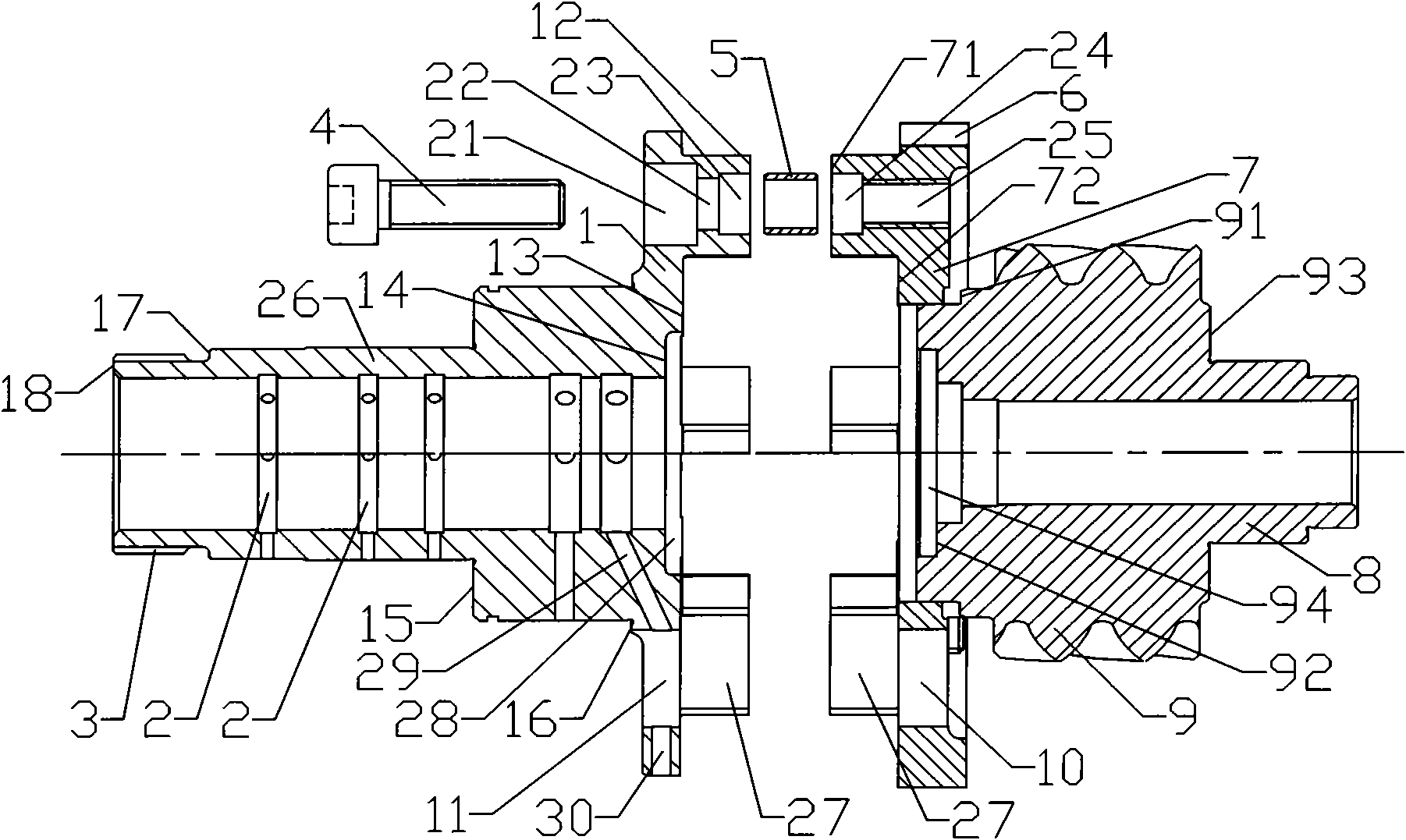

[0142] Embodiment 3: as attached Figure 5 As shown, a planetary carrier includes a planetary carrier body. The planetary carrier body includes two planetary carrier members. The two planetary carrier members are independent individuals. The two planetary carrier members are connected to form the planetary carrier body. The two planetary carrier members The connection method is a detachable connection, and the connection method of the two planetary frame members is a bolt connection.

[0143] The two planetary carrier members are the first planetary carrier member 1 and the second planetary carrier member 7, the first planetary carrier member 1 is a planetary carrier member provided with a sleeve support portion 26, and the second planetary carrier member 7 is connected to the gear 9 The first planetary carrier member 1 is provided with a groove 28 on the inner end surface, and the number of bolts 4 is four, and the four bolts 4 are evenly distributed along the circumferential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com