Steel-plastic composite strips and steel-plastic composite drainage tubing manufactured by same

A technology of steel-plastic composite tape and drainage pipes, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., which can solve the problems of difficulty in ensuring the rigidity of pipe rings, increasing manufacturing complexity, and losing anti-corrosion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

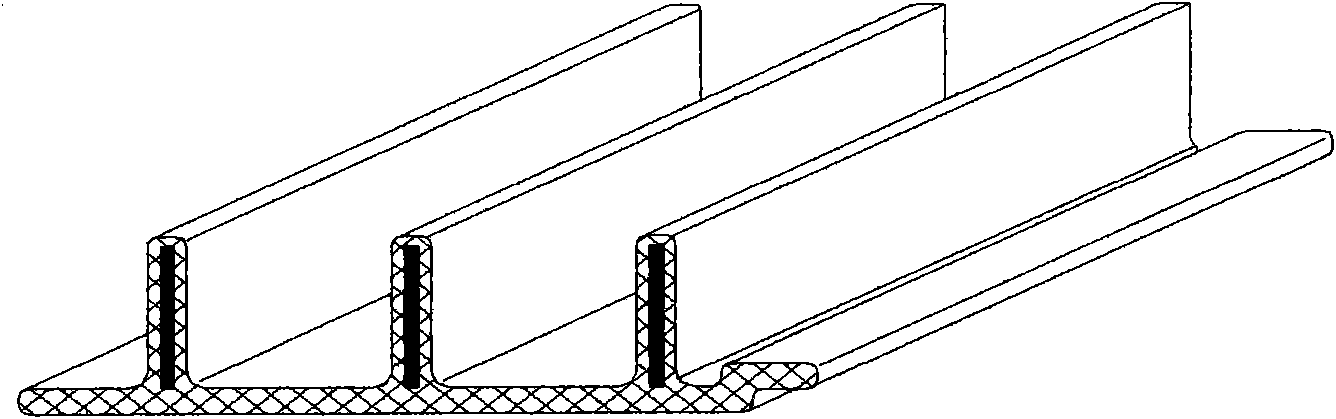

[0022] Figure 4 Shown is a steel-plastic composite strip of the present invention, which is composed of a plastic flat belt 1, a reinforcing rib 2 and a composite inside the reinforcing rib Type reinforced steel belt 3 is constituted. The reinforcing ribs 2 are perpendicular to the plastic flat belt and are distributed equidistantly. An edge-folded overlap structure is provided on one edge of the plastic flat belt 1, and the folding direction must be consistent with the top edge of the reinforcing rib 2.

[0023] Figure 5 Shown is another embodiment of the steel-plastic composite strip of the present invention, which is similar to Figure 4 The only difference shown is that the reinforced steel strip compounded in the rib is of the "[" type.

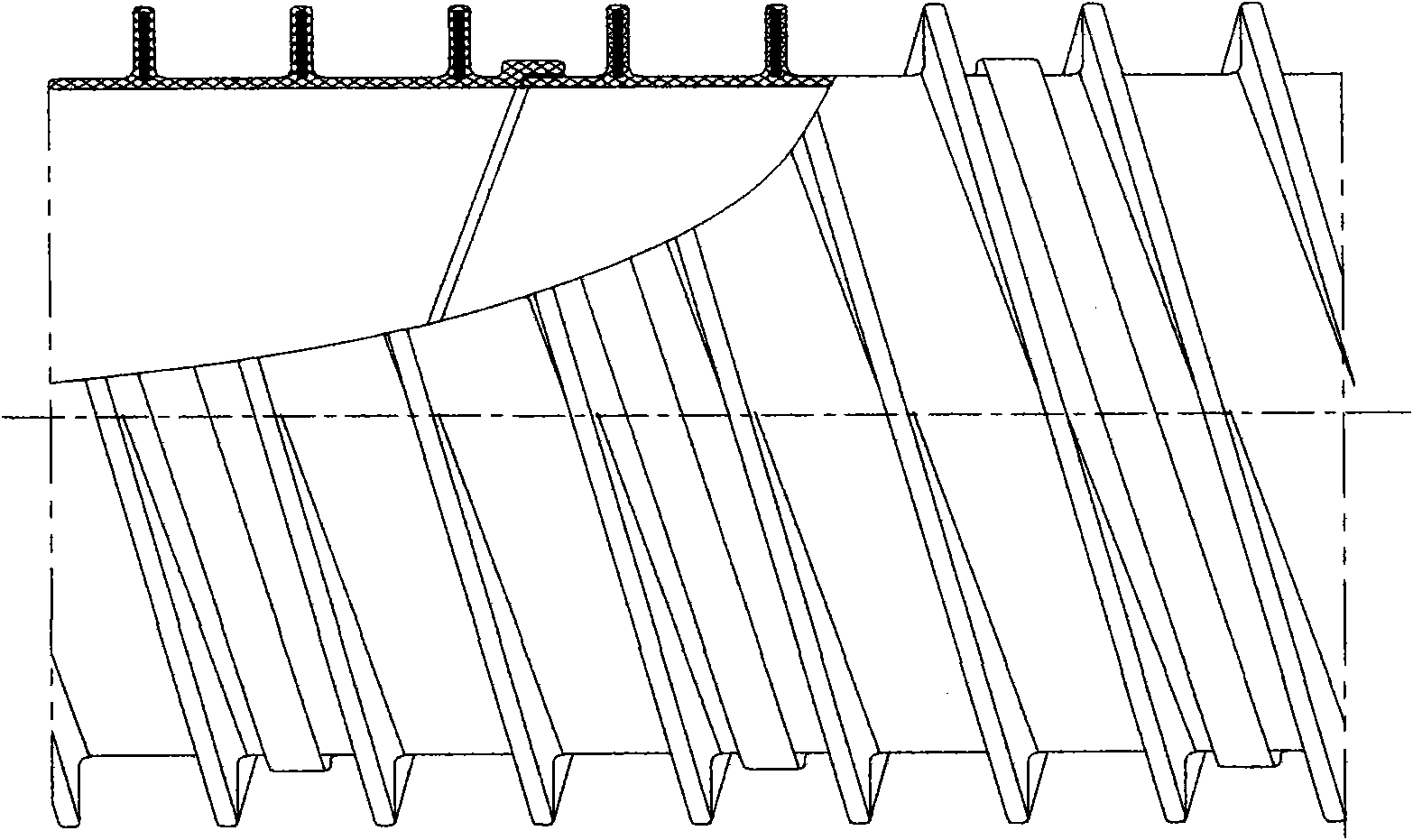

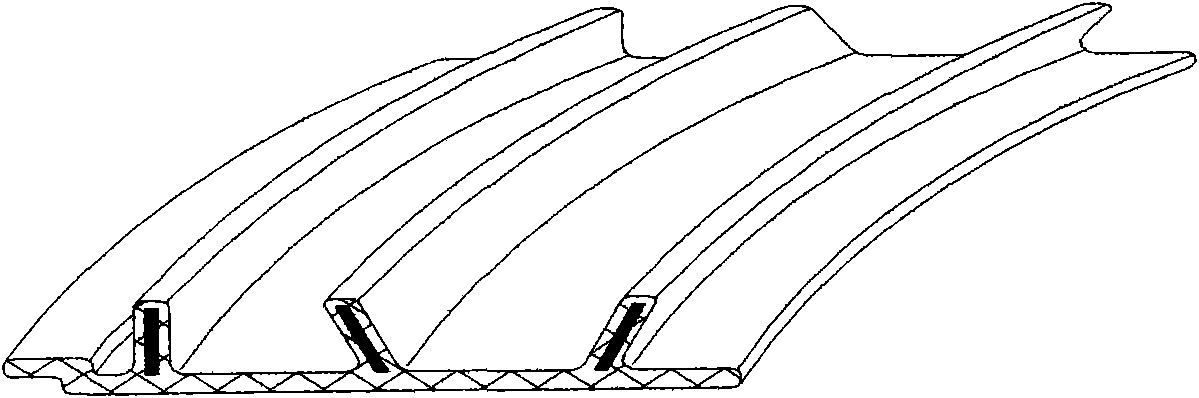

[0024] Image 6 Shown is a steel-plastic composite drainage pipe of the present invention. The pipe is made of Figure 4 The strip shown is wound, extruded and welded. It consists of a pipe body 4 with a uniform wall thickness perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com