Alternately heating solar straw bale drying device

A technology of drying equipment and solar energy, which is applied in the directions of solar thermal power generation, lighting and heating equipment, solar thermal devices, etc., can solve the problems of long drying time and loss of effective nutrients of forage grass, etc., and achieve the effect of high drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

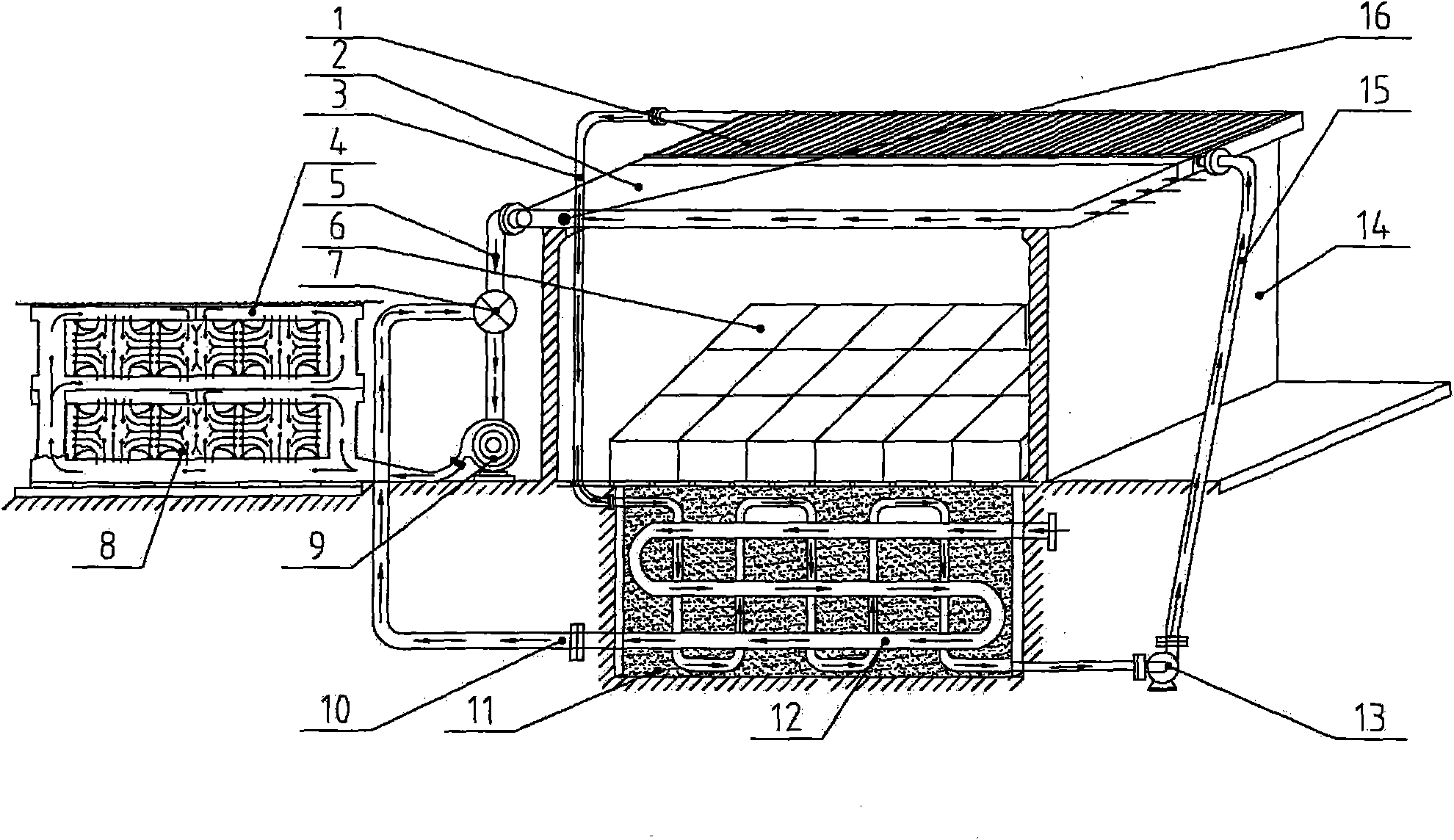

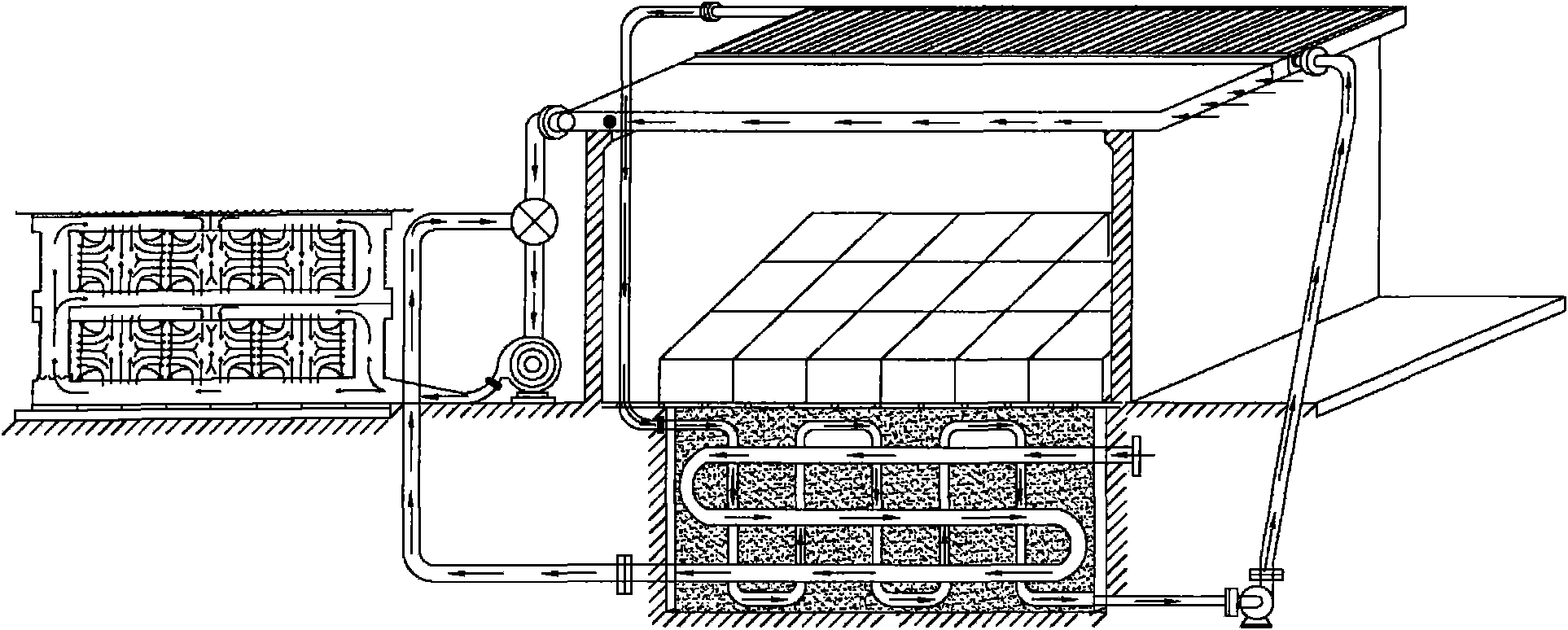

[0007] As shown in the figure, a plate heat collector 2 and a vacuum tube heat collector 1 are respectively installed at the front and rear of the grass storage bin 13 facing the sun and tilting the top cover. One side of the plate heat collector 2 communicates with the outside air, and the other side is connected with the fan 8 through the air duct 5 and the automatic control valve 7 . The water pipe 14 on the right side of the vacuum tube heat collector 1 snakes through the heat storage cement block 10 through the water pump 12 , and then communicates with the left side of the vacuum tube heat collector 1 through the water pipe 3 . The vacuum tube collector 1 is filled with water. The bale 8 to be dried is put in the bale drying equipment 4, and the bale drying equipment 4 bottom is an air passage communicated with the blower fan 9. The heat storage cement block 11 is placed underground in the grass storage bin 14 bottoms. A serpentine air duct 12 passes through the heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com