SFIF code pre-reading method for ICT testing station

A test station and pre-reading technology, which is applied in the field of SFIF pre-reading codes, can solve the problems of low production efficiency and achieve the effects of improving production efficiency, good use value, and saving code reading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

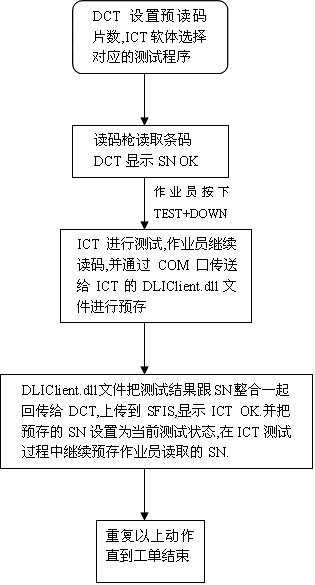

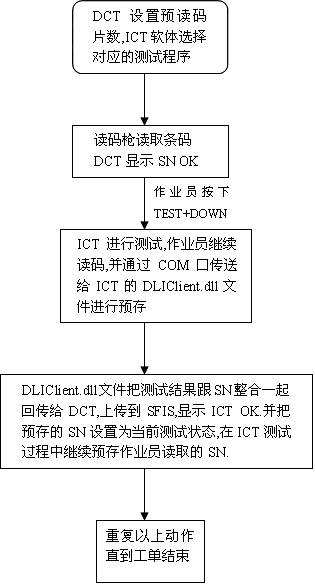

[0014] Such as figure 1 As shown, the present invention provides a kind of SFIF pre-read code method for ICT test station, comprise SMT-2.0 data acquisition device and ICT tester, it is characterized in that:

[0015] (1), use code reading to rush to read the barcode, and the DLIClient.dll file in the test software of the ICT tester pre-stores the barcode that is passed by the code reading;

[0016] (2) After the ICT tester is tested, the DLIClient.dll file integrates the test result with the barcode and sends it back to SFIS;

[0017] (3) Mark the pre-stored SN as the current test status, and send it to the ICT test software, and wait for the test result;

[0018] (4) Repeat steps (2) and (3).

[0019] In this implementation example, the above-mentioned SMT-2.0 data collector, referred to as DCT, is a terminal connection device used to collect data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com