Method and device for regulating emission surface of ultrasonic transducer probe to be parallel to reflecting plate

A reflector, ultrasonic technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of insufficient reliability and accuracy, reducing experimental efficiency and effect, time-consuming and laborious, etc., achieving high accuracy, concise operation, Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

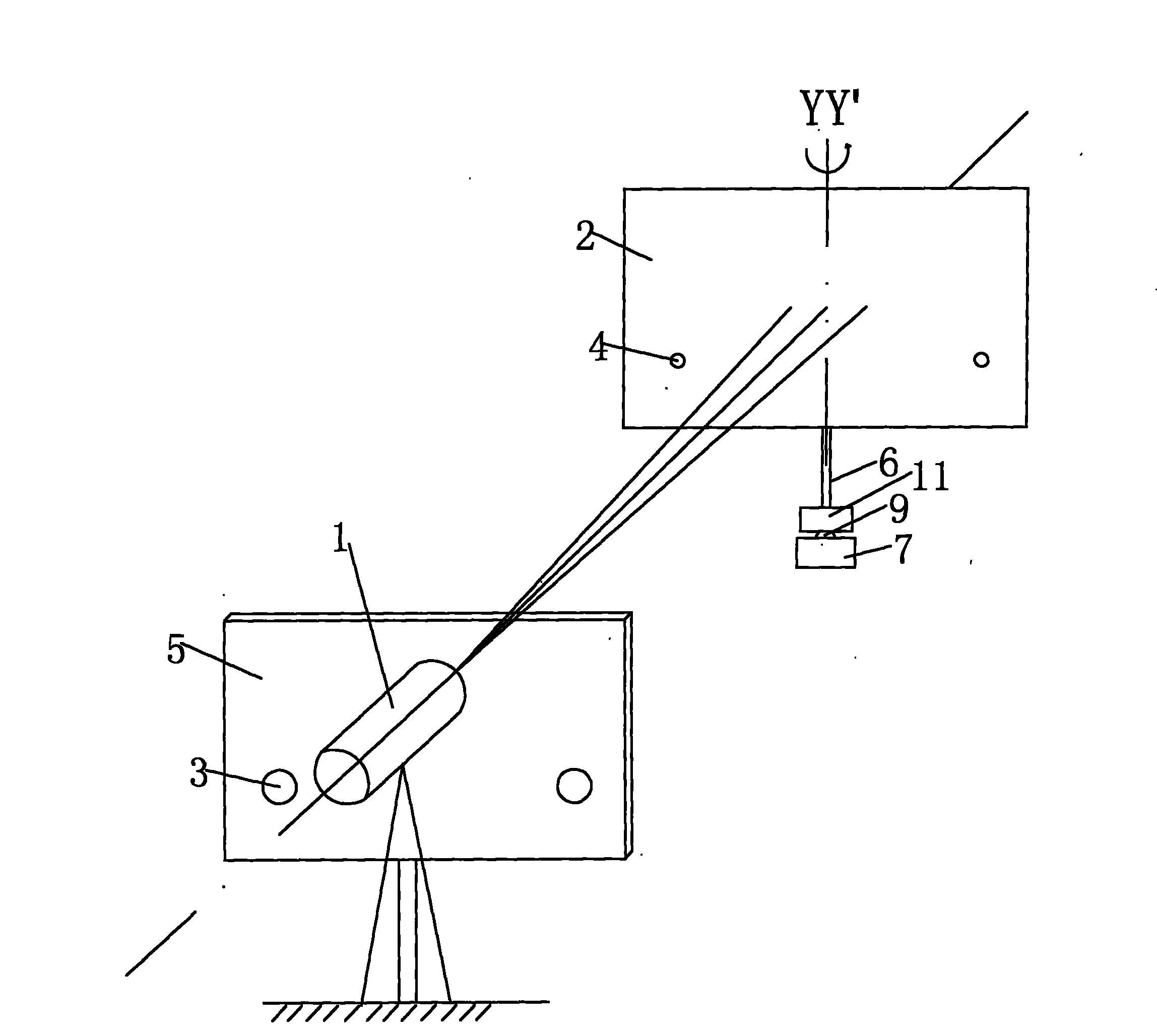

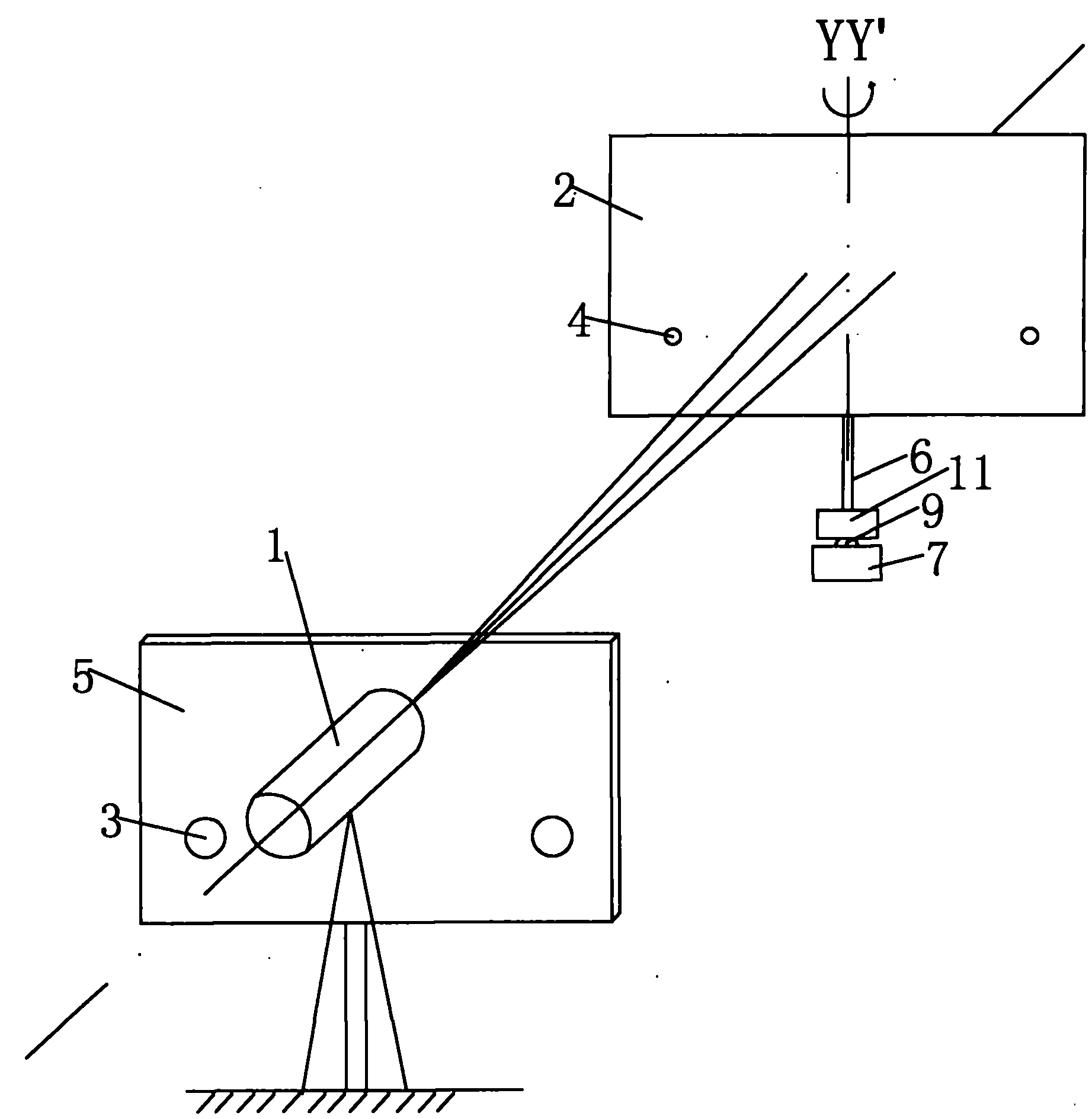

[0019] Embodiment: a method for adjusting the emitting surface of the ultrasonic transducer probe to be parallel to the reflector, comprising the steps of:

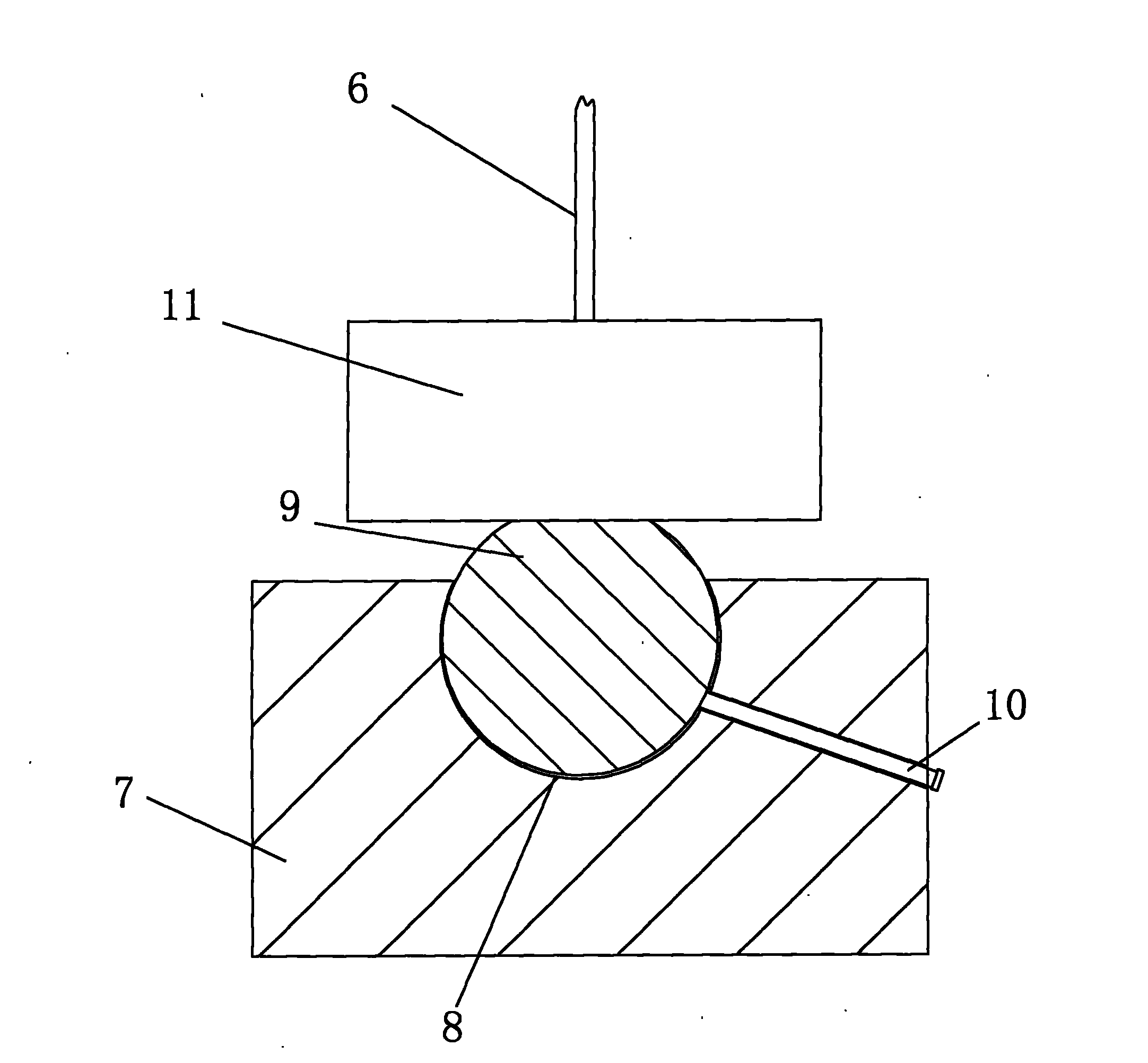

[0020] (1), install two laser transmitters on the side of the ultrasonic transducer probe, and adjust the position of the laser transmitter so that the emitted laser light is perpendicular to the emitting surface of the probe, and two laser receiving points are correspondingly installed on the reflector Sensor, first adjust when the ultrasonic transducer probe’s emitting surface is initially parallel to the reflector, the two laser beams emitted by the laser transmitter are just aligned with the two laser receiving point sensors in the reflector respectively; the initial parallel adjustment method is as follows : Start the ultrasonic transducer probe, connect the ultrasonic transducer probe to the oscilloscope, repeatedly adjust the position of the reflector, and use the oscilloscope to observe the ultrasonic echo return t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com