Shallow groove, manufacturing method thereof and shallow groove isolation structure

A manufacturing method and shallow trench technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as uneven deviation, deviation of semiconductor device size from expectations, complex processes, etc., and achieve convenient filling and deviation. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

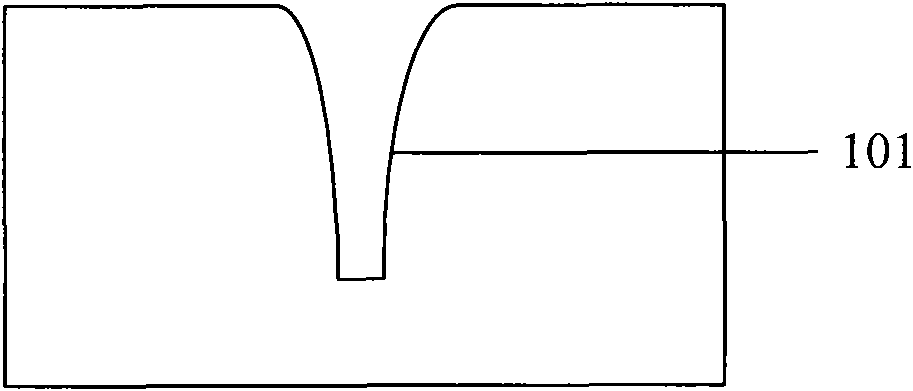

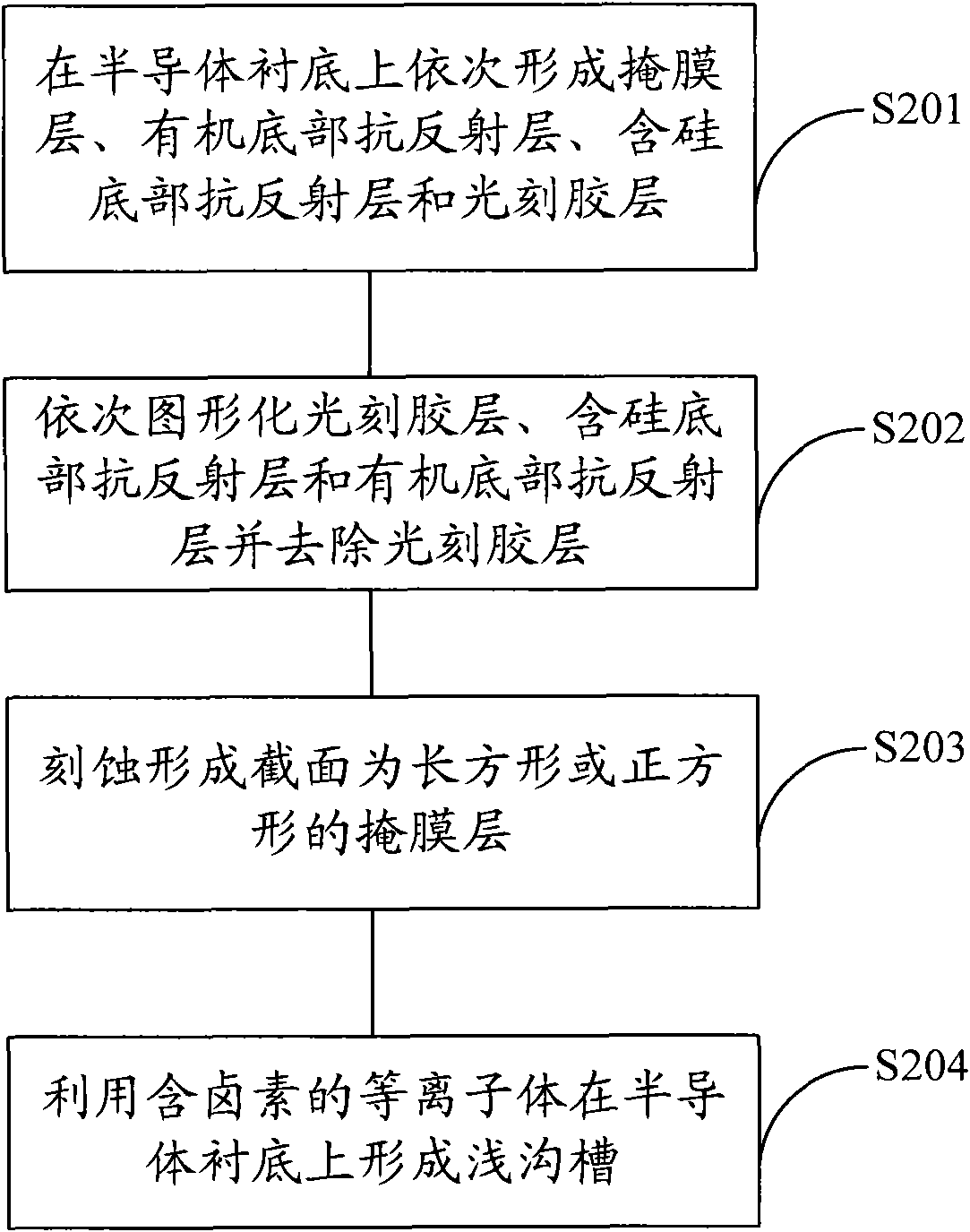

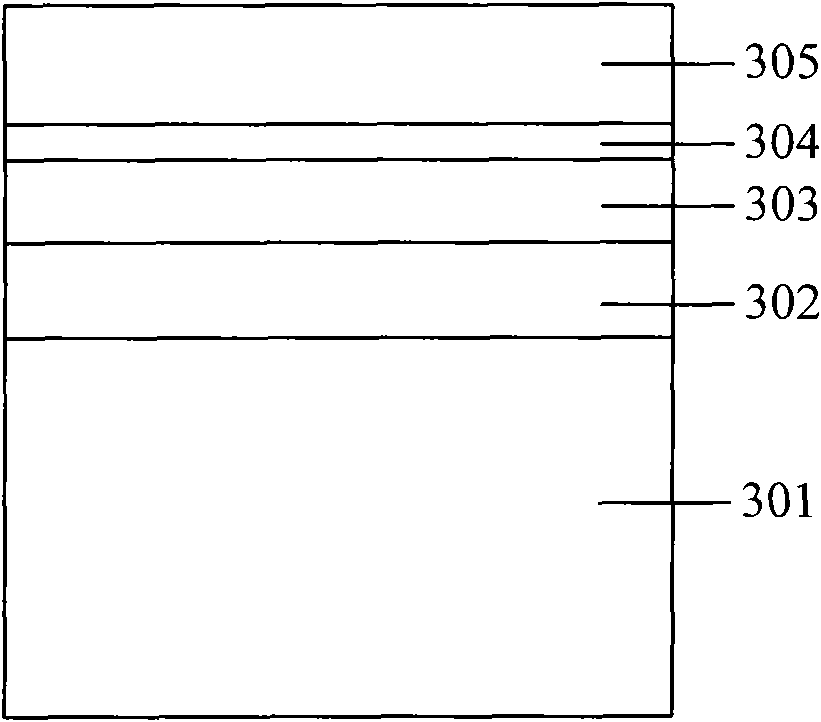

[0022] The inventors of the present invention found that when manufacturing shallow trench isolation structures, such as figure 1 As shown, if the cross-sectional shape of the shallow trench 101 in the width direction is an inverted "vase" shape, it is convenient to fill the oxide into the shallow trench 101 without blocking the opening of the shallow trench 101 . The so-called inverted "vase" shape here means that the inner wall of the shallow groove 101 is in the figure 1 The cross-section in the width direction thereof is shown concave inward, so that the width of the shallow trench 101 decreases non-linearly from the opening to the bottom. Therefore, according to one aspect of the present invention, there is provided a shallow trench used for isolating semiconductor devices, the sidewall of the shallow trench is concave in cross-section in the width direction thereof. Certainly, the present invention also provides a shallow trench isolation structure for semiconductor dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Source power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com