Submerged Arc Furnace Secondary Reactive Power Compensation Control System and Control Method

A submerged arc furnace and secondary side technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as lack of compensation effect, over-compensation or under-compensation, and small amount of collected data. Achieve the effect of ensuring data and information sharing, realizing automatic monitoring, and complete parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

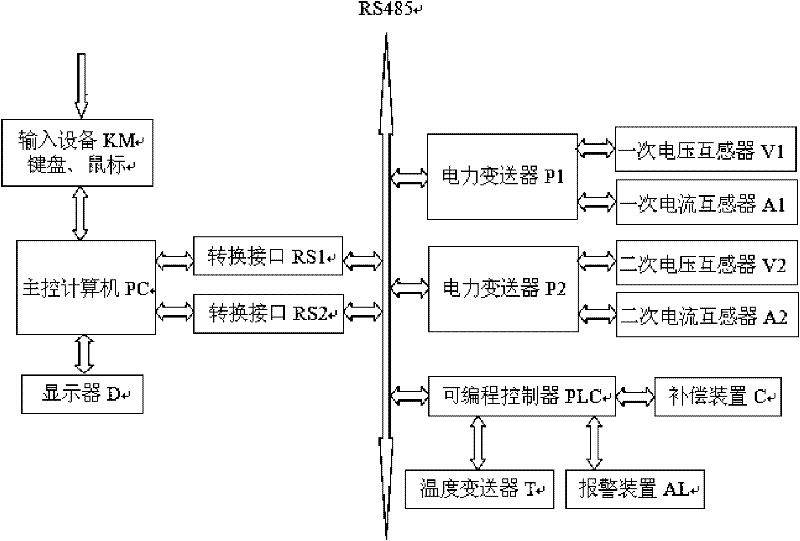

[0046] like figure 1As shown, in addition to the power system PS, the control system also includes the main control computer PC, display D, input device KM (keyboard, mouse), two conversion interfaces RS1 and RS2, two intelligent power transmitters P1 and P2, primary Side voltage transformer V1, primary side current transformer A1, secondary side voltage transformer V2, secondary side current transformer A2, programmable logic controller PLC, temperature transmitter T, compensation device C, alarm device AL and asynchronous Transmission standard interface RS232. The main control computer PC is electrically connected with the display D and the input device KM (keyboard, mouse). Intelligent power transmitters P1, P2 and programmable controller PLC; one port of intelligent power transmitter P1 is electrically connected through a transmission standard interface, and the other port of intelligent power transmitter P1 is electrically connected to primary side voltage transformer V1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com