Electronic metering device for milking in constant volume

A technology of electronic measurement and equipment, applied in milking devices, dairy products, applications, etc., to achieve the effects of overcoming errors, improving accuracy, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

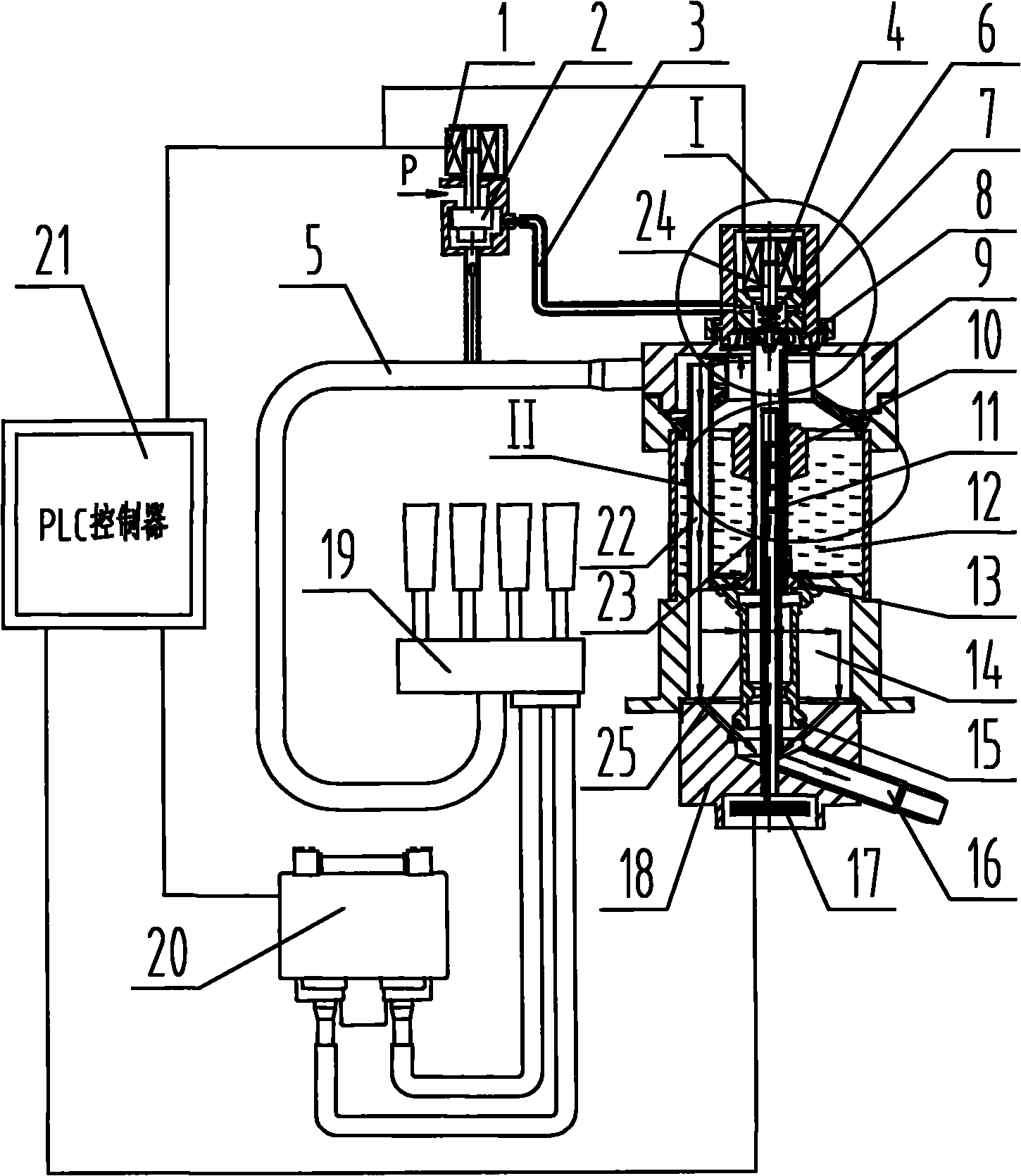

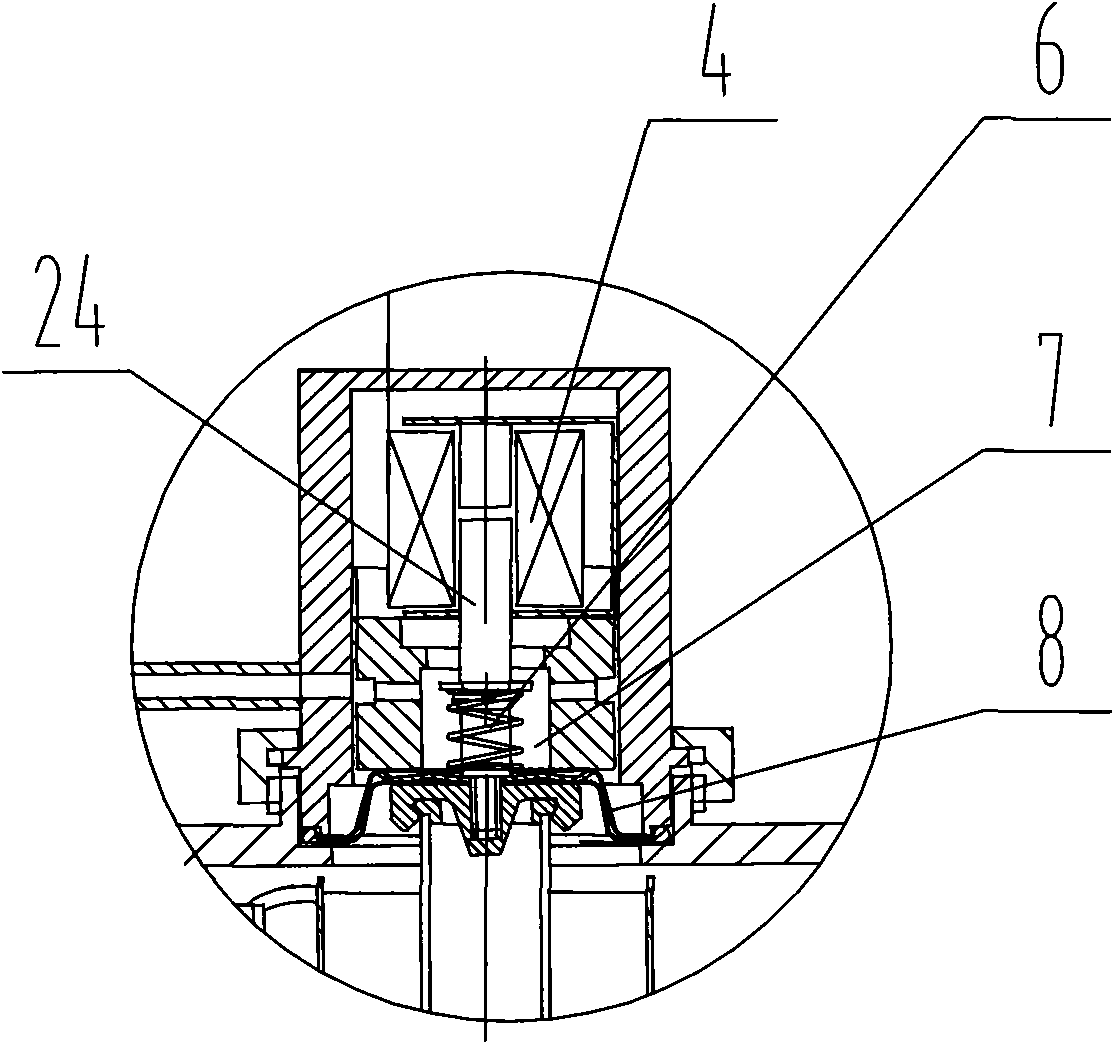

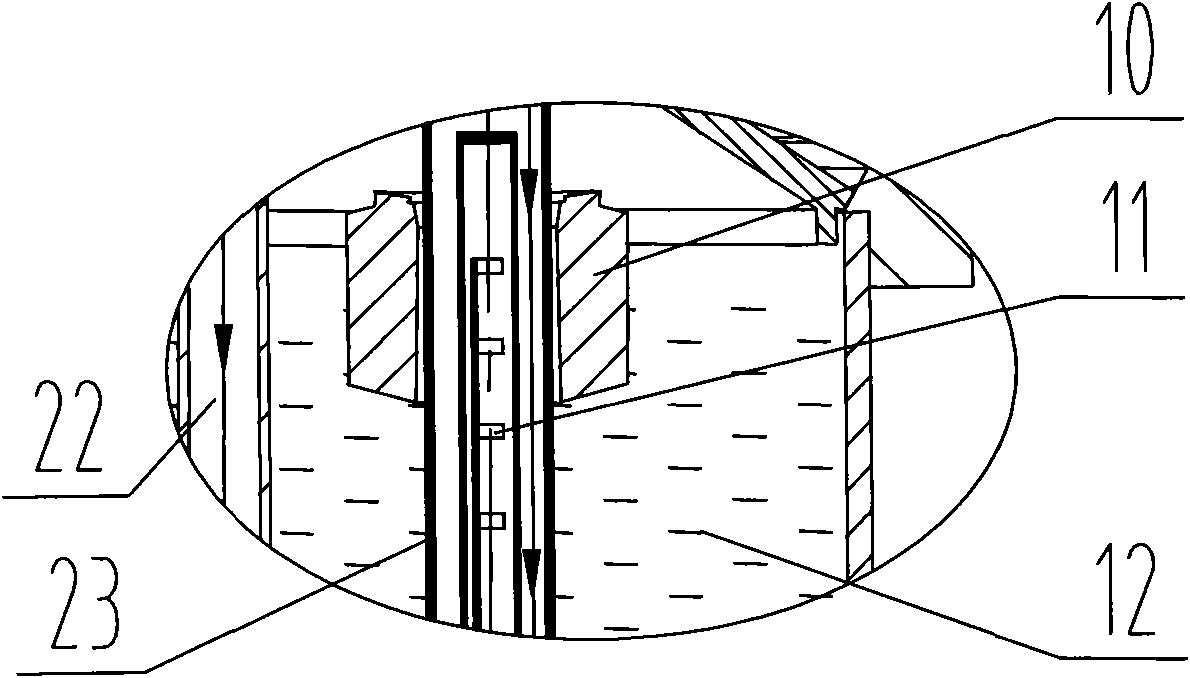

[0025] The structure of the constant-volume milking electronic metering device of the present invention is as follows: figure 1 As shown, it includes air valve electromagnet 1, air valve 2, connecting pipe 3, milk suction pipe 5, jacking spring 6, pneumatic chamber 7, leather cup 8, upper casing 9, magnetic floating ball 10, sensor 11, metering chamber 12 , milk discharge pipe 16, detection circuit 17, lower housing 18, milk collector 19, electronic pulsator 20, PLC controller 21, valve body 23, valve stem body 24. exist figure 1 , figure 2 Among them, the leather cup 8 is set at the upper center hole of the upper casing 9, and the valve body 23 is installed vertically through the center in the metering chamber 12. The top of the valve body 23 is placed under the leather cup 8, and the top Lifting spring 6 is installed on the upper surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com