Automobile engine valve blank cross wedge rolling accurate forming method

A technology of automobile engine and cross wedge rolling, which is applied in the direction of rolling, metal rolling, metal rolling, etc. It can solve the problems of large length-to-diameter ratio, small diameter of valve blank stem, sensitive process parameters, etc., and achieves improved production efficiency, The effect of improving mold life and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

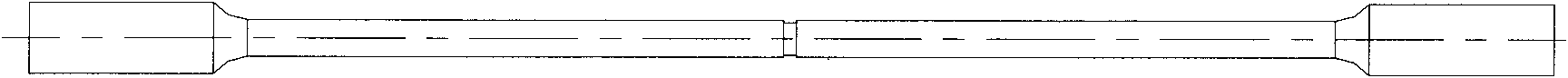

example 1

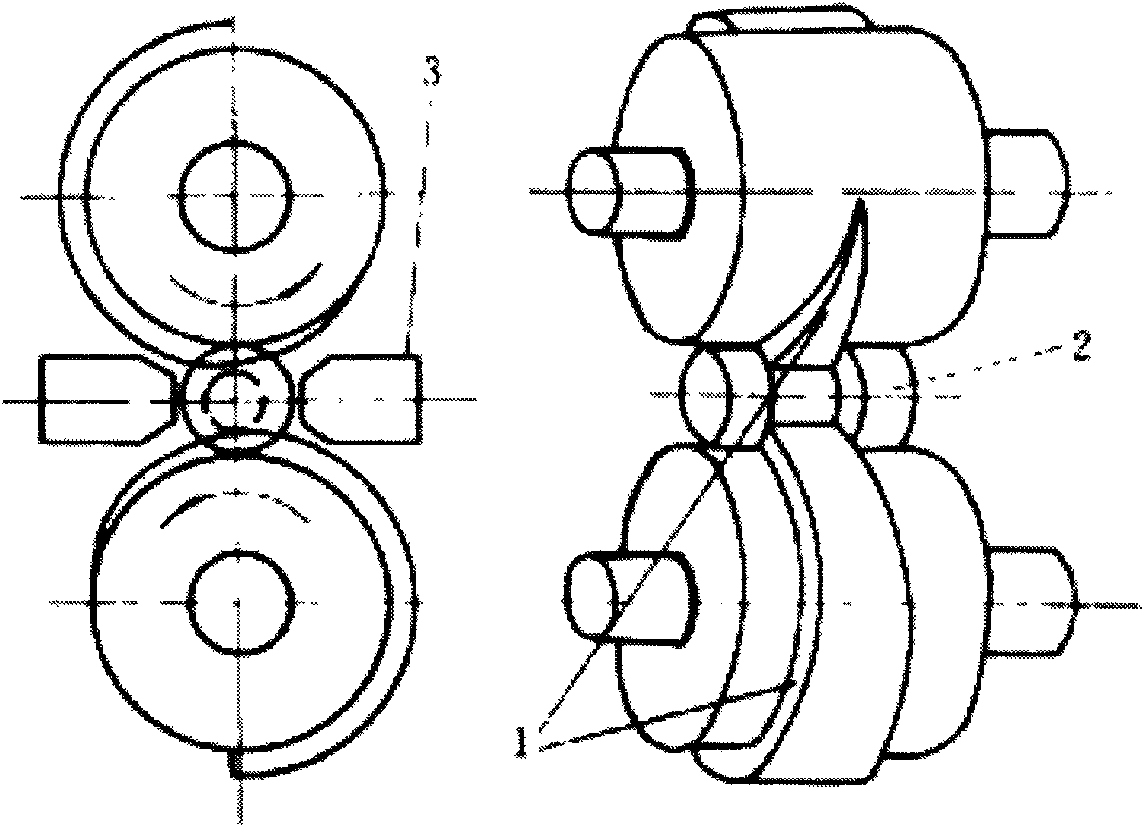

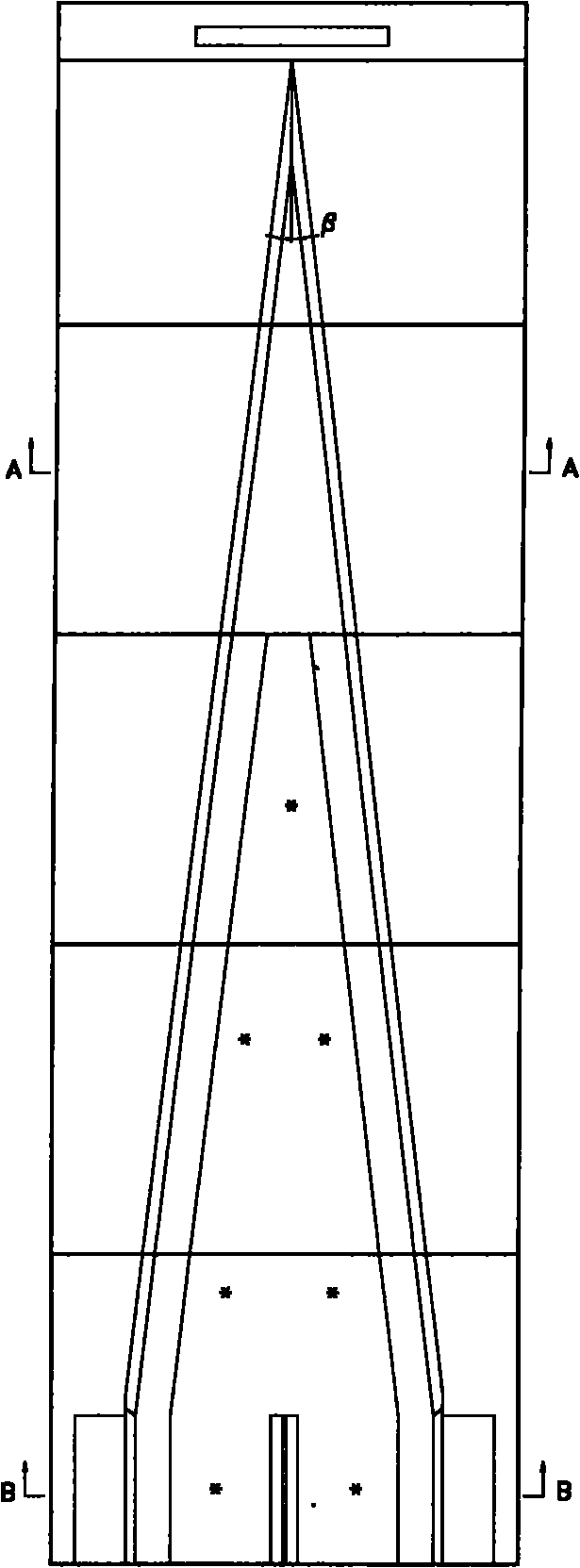

[0026] like Image 6 An example of a precisely formed automotive engine valve blank of the present invention is shown. Install a pair of rolls with a mold with a forming angle of α=26°, a widening angle of β=6°, and a transition fillet radius of R=10mm on the cross wedge rolling mill. The mold expansion diagram is as follows image 3 shown. After heating a metal round bar with a diameter of 16mm and a length of 169mm to 1150°C through an electromagnetic induction furnace, it is placed in the pass between the upper and lower molds through an axial feeding device (such as figure 2 shown), under the action of the wedge, it rotates under the action of the wedge, after continuous radial compression and axial extension deformation, the formed rolled piece is cut from the middle to form a length of 175mm, the radius of the step transition fillet is 10mm, and the diameter of the thin rod is 8.5mm, a pair of automotive engine valve blanks with a length of 124.2mm.

example 2

[0028] A pair of rolls with a mold with a forming angle of α=30°, a widening angle of β=5°, and a transition fillet radius of R=5mm is installed on the cross wedge rolling mill. After the metal round bar with a diameter of 15mm and a length of 179mm is heated to 1180°C by an electromagnetic induction furnace, it is placed between the upper and lower molds through an axial feeding device, and it rotates under the action of a wedge to continuously compress radially. 1. After axial extension and deformation, cut the formed rolled piece from the middle to form a pair of automobile engine valve blanks with a length of 183mm, a step transition fillet radius of 5mm, a thin rod diameter of 8.5mm, and a length of 132mm.

example 3

[0030] A pair of rolls with a mold with a forming angle of α=23°, a widening angle of β=8°, and a transition fillet radius of R=15mm is installed on the cross wedge rolling mill. After the metal round bar with a diameter of 16mm and a length of 170mm is heated to 1100°C by an electromagnetic induction furnace, it is placed between the holes of the upper and lower molds through an axial feeding device, and it rotates under the action of a wedge to continuously compress radially. 1. After axial extension and deformation, the formed rolled piece is cut from the middle to form a pair of automobile engine valve blanks with a length of 176mm, a step transition fillet radius of 15mm, a thin rod diameter of 8.5mm, and a length of 125mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com