Pulverulent body striking-off device and control method thereof

A powder and control system technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve problems such as difficult to meet fast processing, uneven powder, unevenness, etc., and achieve the effect of shortening the scraping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

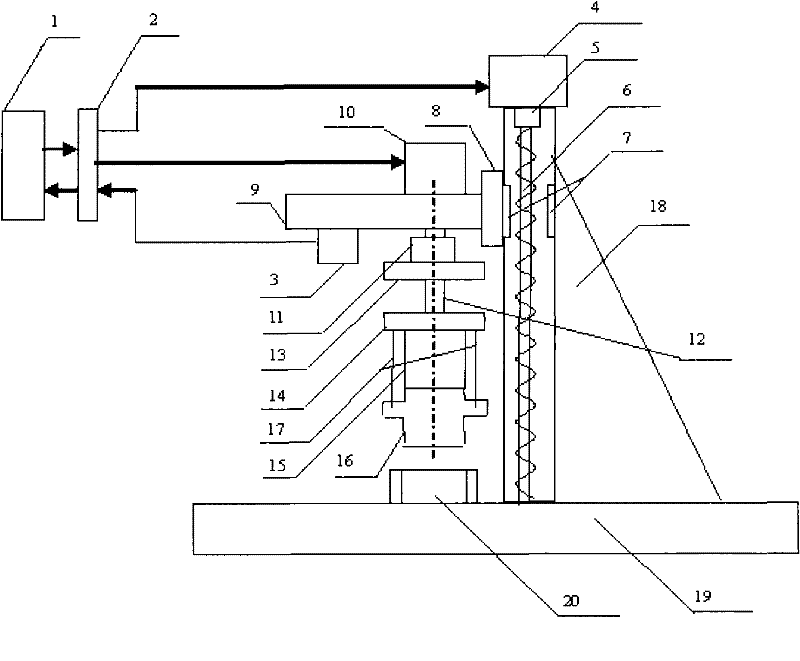

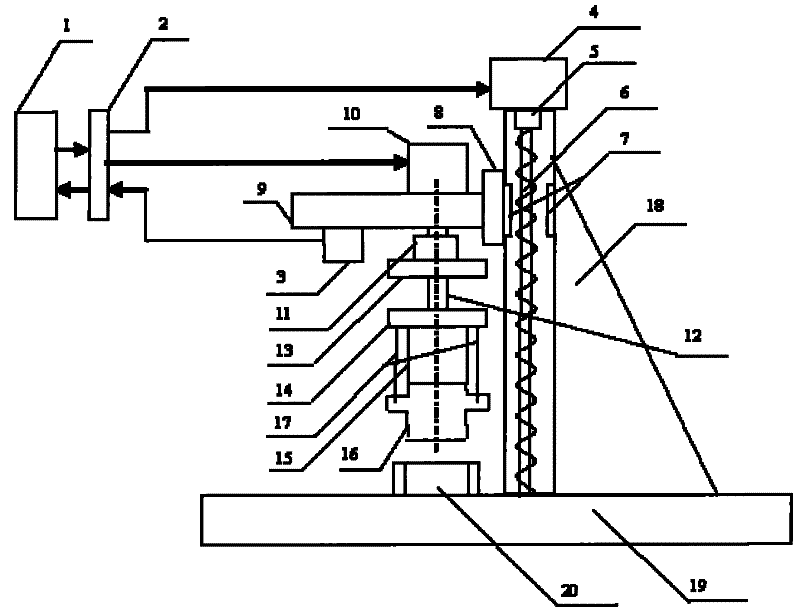

[0036] Such as figure 1 As shown, a powder scraping device includes a control system, a scraping system and a platform system, wherein:

[0037] Described platform system comprises support 18, platform 19 and feed box 20, and described support 18 is fixed on described platform 19, is mainly used in supporting described scraping system; Described feed box 20 is located on described platform 19 and It is located below the scraper 16 (directly below in this embodiment) for collecting powder.

[0038] The scraping system includes a Y-direction motor 4, a first coupling 5, a screw 6, a nut 7, a slider 8, a rotating motor seat 9, a rotating motor 10, a second coupling 11, an output shaft 12, an electromagnet 13. Suction plate 14, scraper seat 15, scraper 16 and pull nail 17, the Y-direction motor 4 is connected to the screw 6 through the first coupling 5, the screw 6 is connected to the slider 8 through the nut 7, and the slider The other side of the block 8 is connected to the ro...

Embodiment 2

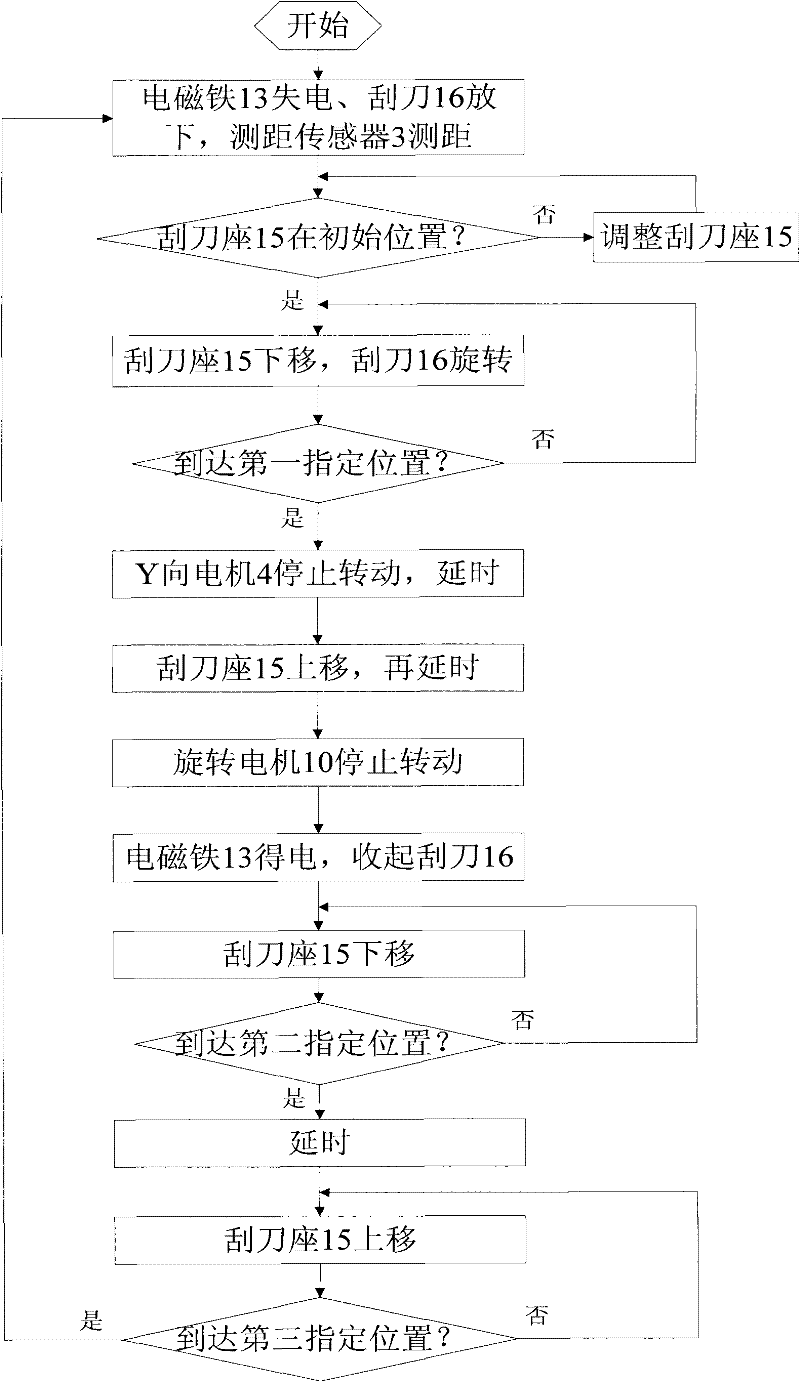

[0047] A method for controlling powder leveling, using the powder leveling device described in Embodiment 1, the flow chart of which is as follows figure 2 shown. The specific description is as follows:

[0048] 1) The electromagnet 13 is de-energized, the scraper 16 is put down, and the ranging sensor 3 measures the distance;

[0049] 2) Determine whether the scraper seat 15 is at the initial position, if so, go to step 3), otherwise adjust the scraper seat 15 so that the scraper seat 15 is at the initial position, go to step 2);

[0050] 3) Rotate the Y-direction motor 4 to move the scraper seat 15 downward, and at the same time, the rotating motor 10 rotates to drive the scraper 16 to rotate;

[0051] 4) Judging whether the scraper seat 15 has reached the first designated position, if yes, then the Y-direction motor 4 stops rotating, after a period of delay, enter step 5), if not, turn to step 3);

[0052] 5) Rotate the motor 4 in the Y direction to move the scraper sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com