Fixed connection method of chip lifting hook piece

A hook piece and hook technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of manufacturing difficulty with low influence factors, high requirements for manufacturing equipment, and many influence factors, so as to achieve good implementation effect, Effects with low manufacturing difficulty and few affected factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

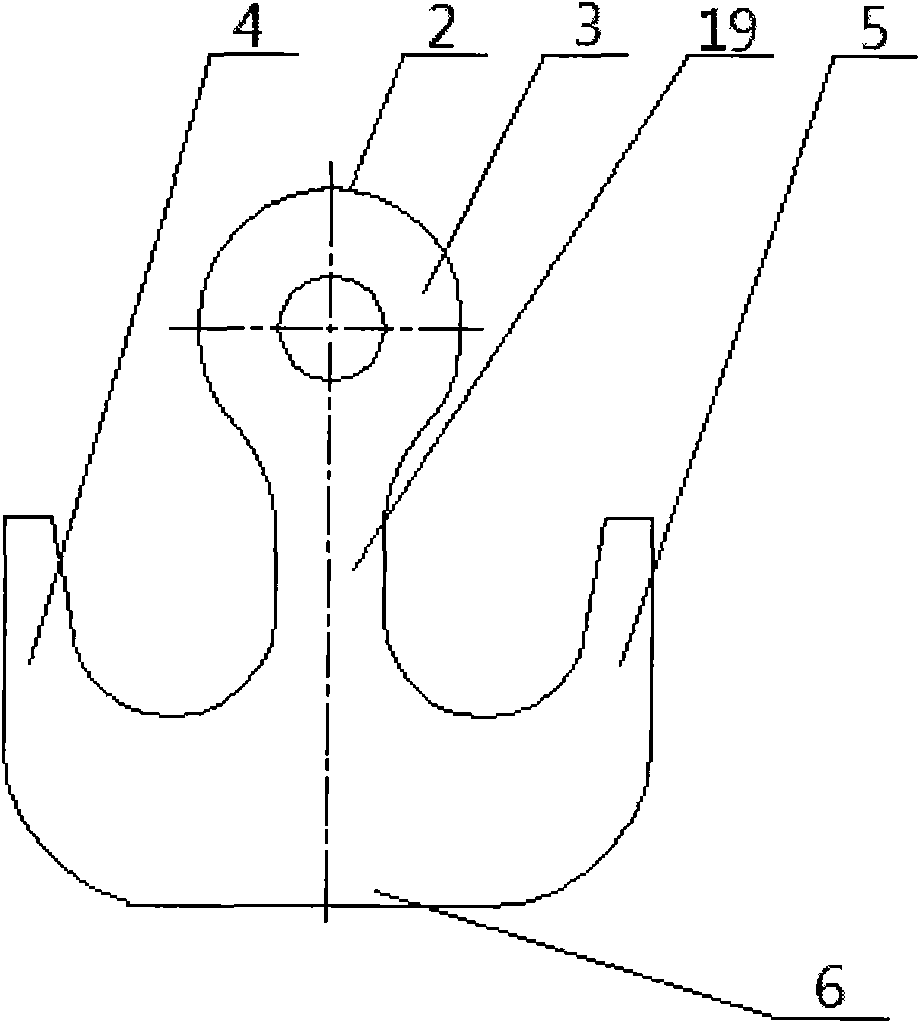

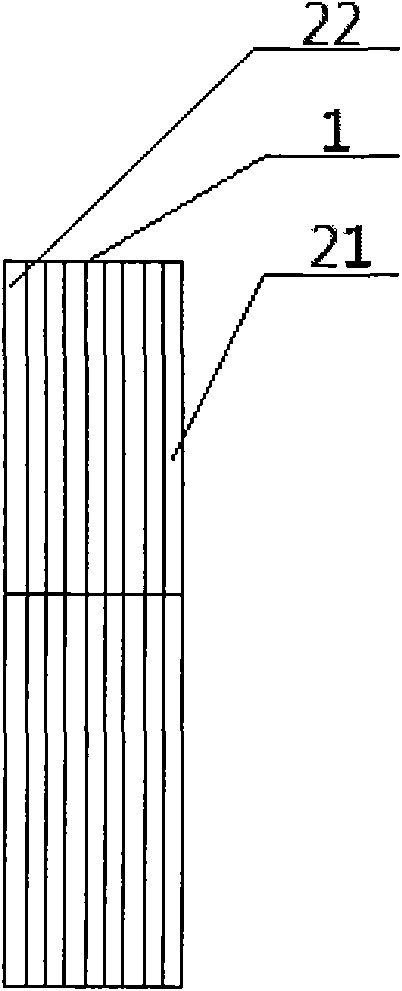

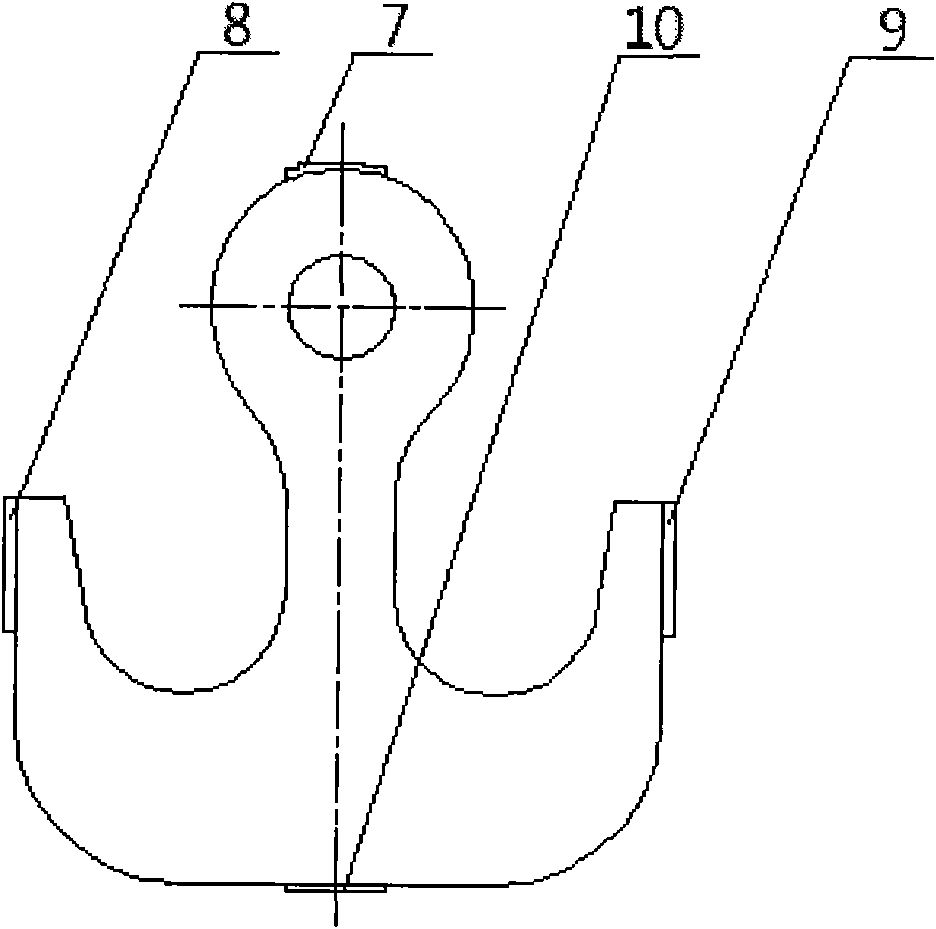

[0048] see Image 6 , the piece-type hook that the present embodiment needs to manufacture comprises nine hook pieces, each piece thickness is 30mm, adapts to the lifting requirement of 250 tons, prepares to evenly arrange 15 positioning holes on the hook piece, respectively for the connecting part Positioning hole 11, left hook end positioning hole 12, left hook shaft positioning hole 13, right hook end positioning hole 14, right hook shaft positioning hole 15, left corner positioning hole 16, right corner positioning hole 17, hook bottom positioning hole 18. Positioning hole 20 of the lower connection part, positioning hole 23 of the left hook, positioning hole 24 of the top of the left turn, positioning hole 25 of the bottom of the left hook, positioning hole 26 of the middle of the right hook, positioning hole 27 of the top of the right turn and positioning hole 28 of the bottom of the right hook , select the left hook shaft positioning hole 13, the right hook shaft positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com