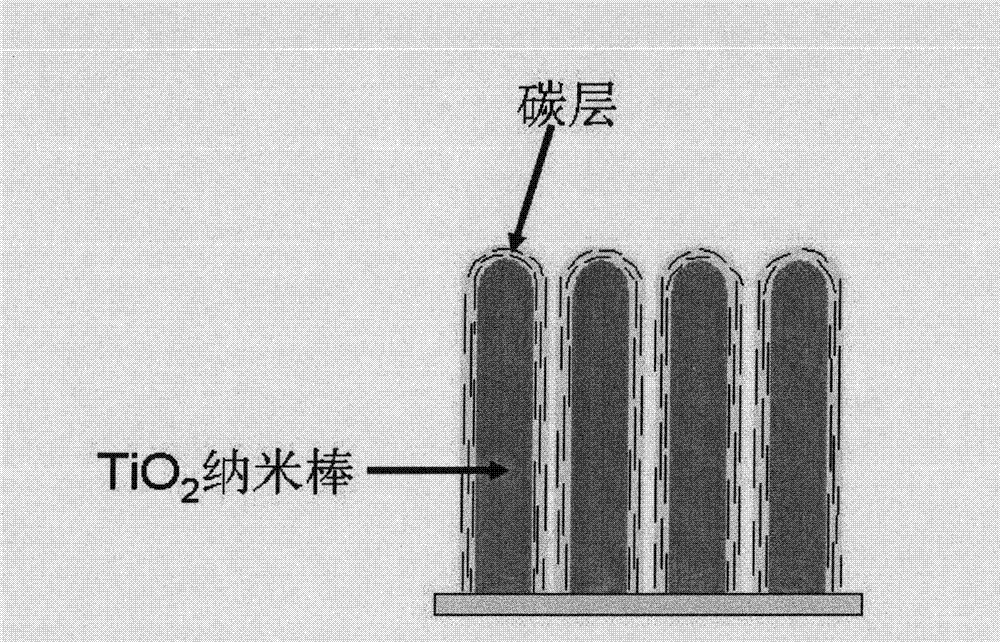

TiO2 nuclear shell structure nano rod array coated with carbon bed and preparation method thereof

A nanorod array, core-shell structure technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problem of no literature report on the preparation method of nanorod array, and achieve the advantages of charge separation, regular arrangement and specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

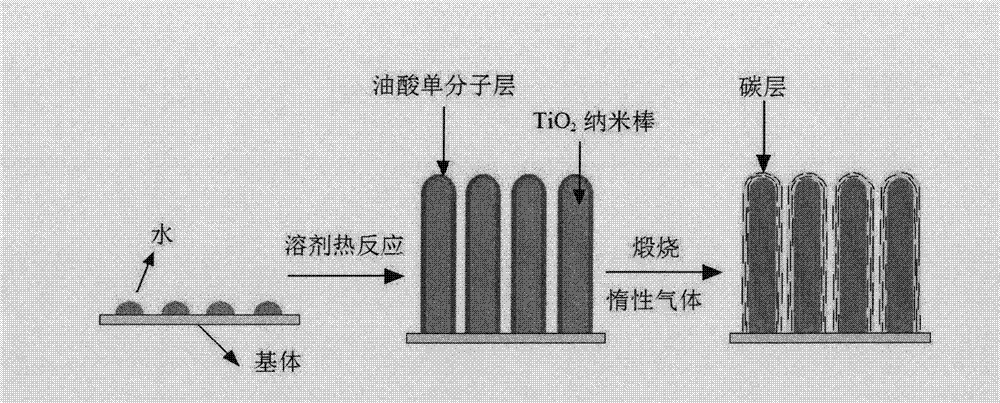

Method used

Image

Examples

Embodiment 1

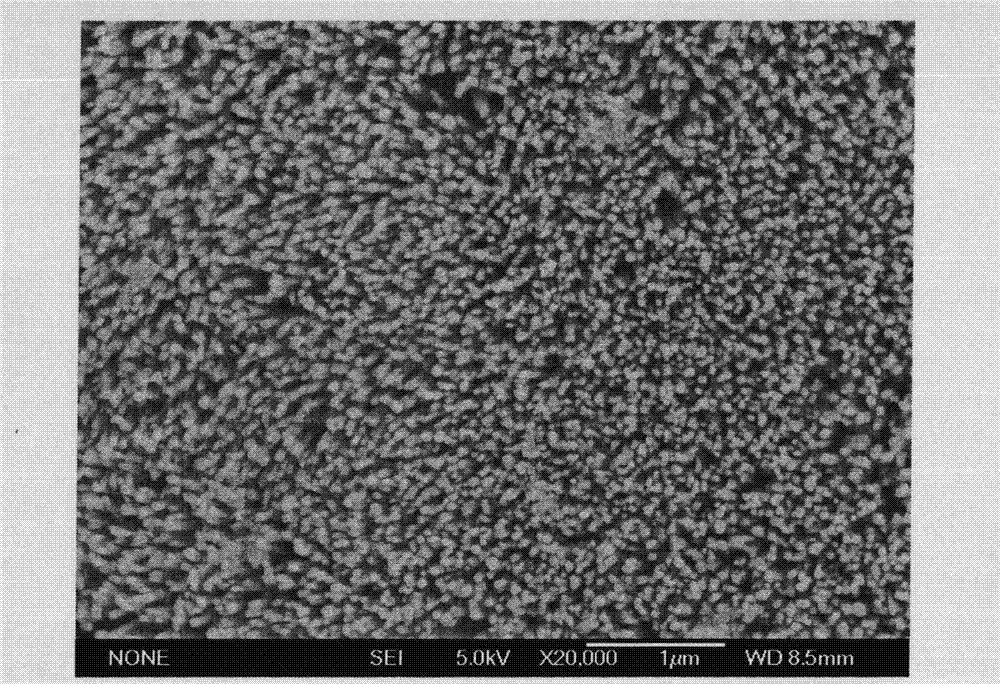

[0039] Mix 10ml of triethylamine, 20ml of oleic acid, 40ml of cyclohexane, 4ml of n-butyl titanate, and 0.05g of ammonium bicarbonate, add a 100ml hydrothermal kettle, and then put clean ITO glass as a hydrophilic matrix. Insulate at 180°C for 24h, take out the ITO glass after natural cooling, wash with ethanol for 5 times, dry in vacuum at 80°C for 12h, and then heat-treat at 500°C for 3h under the protection of high-purity argon to obtain TiO with a carbon layer on the surface. 2 Core-shell nanorod arrays. Scanning electron microscope results showed that, as image 3 Shown: TiO 2 Nanorods perpendicular to the ITO glass matrix, TiO 2 The nanorods are regular and orderly, uniform in thickness and about 50nm in diameter. High-resolution transmission electron microscopy (HRTEM) showed that, if Figure 4 Shown, TiO 2 The thickness of the carbon layer coated on the surface of the nanorod is about 3nm. X-ray diffraction tests showed that, if Figure 5 Shown: TiO 2 The cryst...

Embodiment 2

[0041] Mix 10ml of triethylamine, 20ml of oleic acid, 40ml of cyclohexane, 4ml of n-butyl titanate, and 0.1g of ammonium bicarbonate, add a 100ml hydrothermal kettle, and then put clean ITO glass as a hydrophilic matrix. Insulate at 180°C for 24h, take out the ITO glass after natural cooling, wash with ethanol for 5 times, dry in vacuum at 80°C for 12h, and then heat-treat at 500°C for 3h under the protection of high-purity argon to obtain TiO with a carbon layer on the surface. 2 Core-shell nanorod arrays. Scanning electron microscope results showed that, as Figure 7 Shown: TiO 2 The nanorods are perpendicular to the ITO glass matrix, arranged neatly, uniform in thickness, with a diameter of about 80 nm and a length of about 5 μm. X-ray diffraction test shows that: TiO 2 The crystal form is a mixture of anatase and rutile, and the nanorods are oriented along the 002 crystal plane. The results of Raman spectroscopy show that the carbon layer is a mixture of amorphous carb...

Embodiment 3

[0043] Mix 10ml of triethylamine, 20ml of oleic acid, 40ml of cyclohexane, 4ml of n-butyl titanate, and 0.05g of ammonium bicarbonate, add a 100ml hydrothermal kettle, and then put a clean quartz plate as a hydrophilic matrix. Insulate at 180°C for 24h, take out the quartz plate after natural cooling, wash 5 times with ethanol, dry in vacuum at 80°C for 12h, and then heat-treat at 500°C for 3h under the protection of high-purity argon to obtain TiO coated with a carbon layer on the surface 2 Core-shell nanorod arrays. Scanning electron microscope results showed that: TiO 2 The nanorods are perpendicular to the quartz sheet, arranged neatly, with a diameter of about 50nm and a length of about 5μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com