Combined-type self-expansion package body and manufacturing method thereof

A manufacturing method and self-expanding technology, applied in the direction of bonding methods, record carriers used by machines, instruments, etc., can solve the problems of ignoring the convenience of removal, achieve the effect of convenient recycling and improve convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

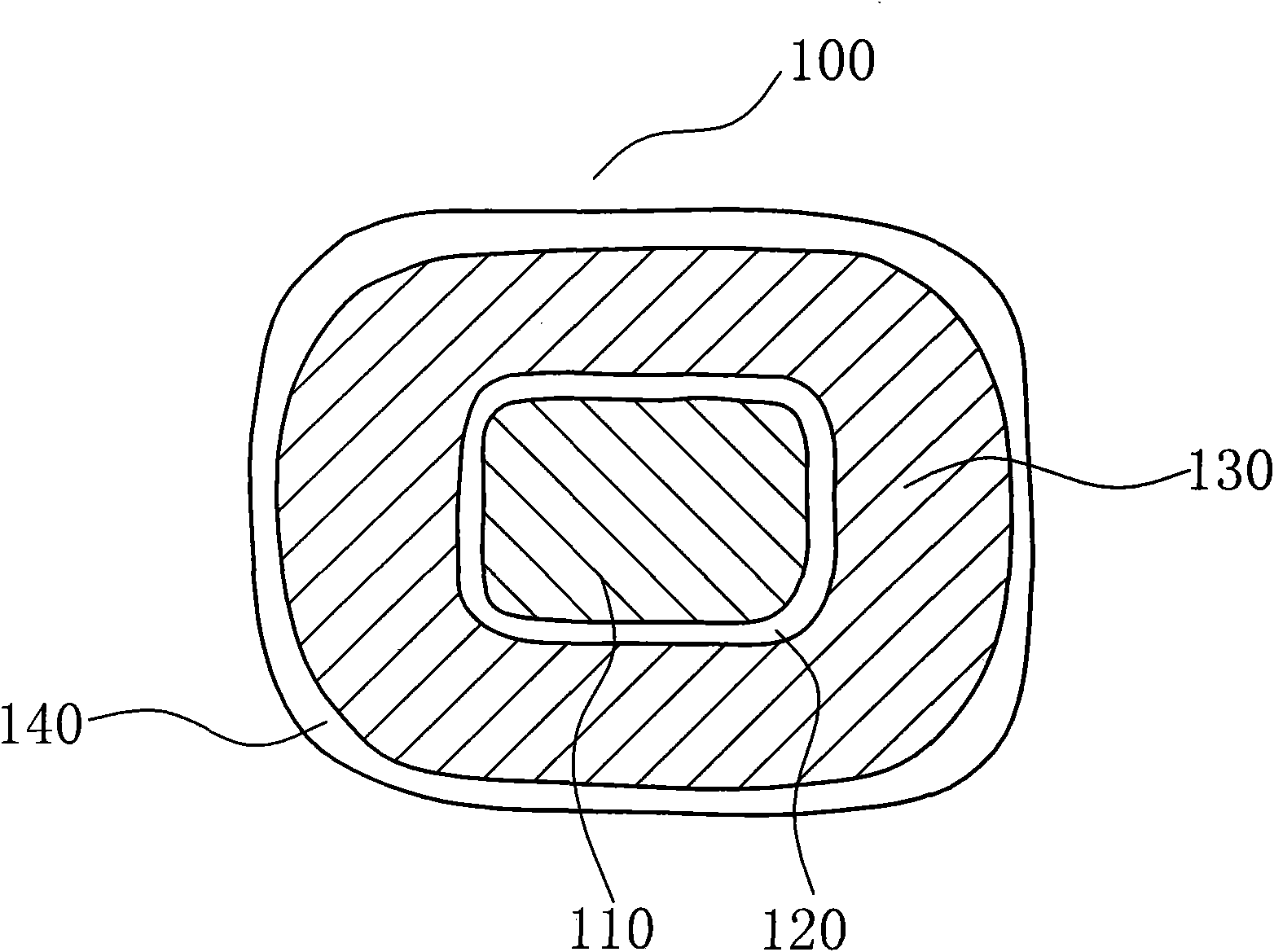

[0043] ginseng image 3 As shown, this figure shows a specific embodiment of the structure of a composite self-expanding package 100, the composite self-expanding package 100 includes a foam material A 110, and is arranged on the periphery of the foam material A110 The foam material A coating layer 120 of the foam material A coating layer 120, the foam material B 130 disposed on the periphery of the foam material A coating layer 120, and the foam material B coating layer 140 disposed on the periphery of the foam material B 130. In this embodiment, the foaming substance A 100 is selected from HCl solution, and the foaming substance A coating layer 120 is realized by using a polyethylene plastic film; corresponding to the foaming substance A 100, the HCl solution is selected, and the foaming substance B 130 is selected from NaHCO 3 Powder, foam material B coating layer 140 is realized by polyethylene plastic film.

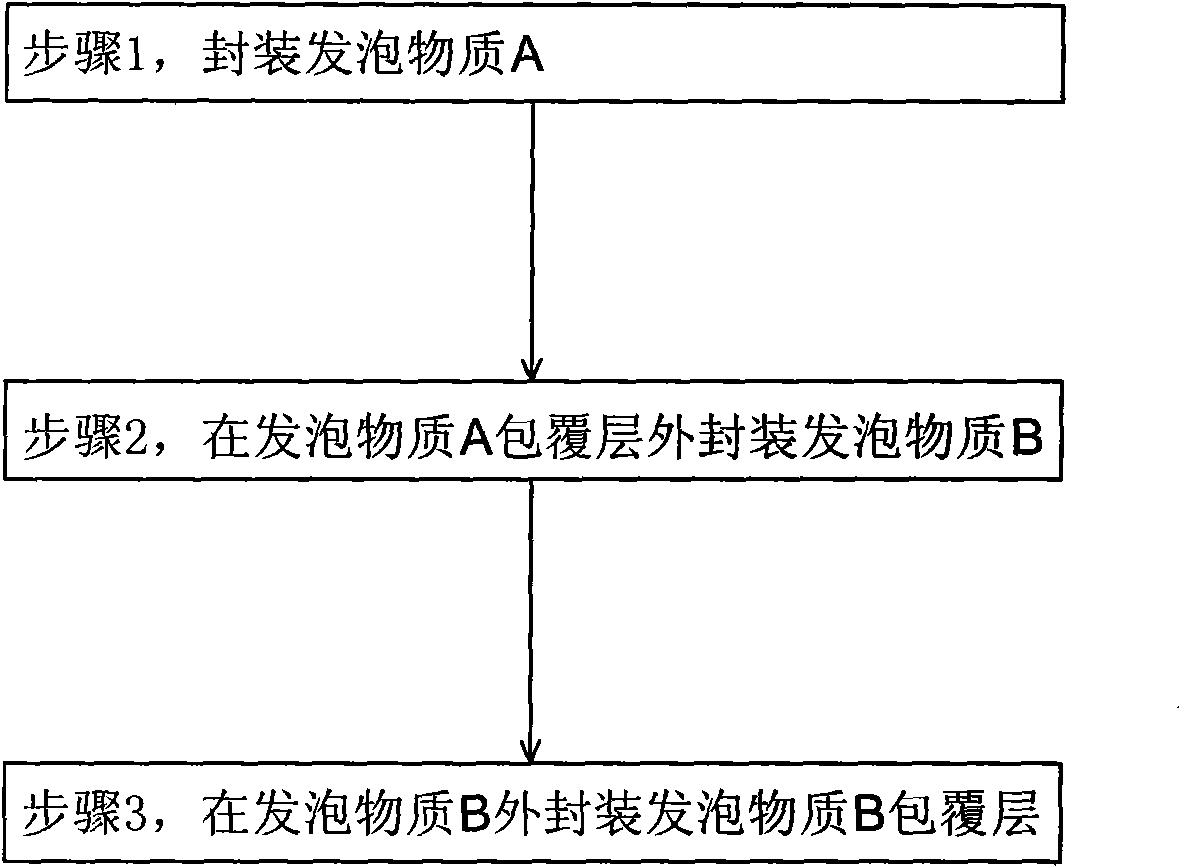

[0044] In this embodiment, the manufacturing method of the com...

specific Embodiment 2

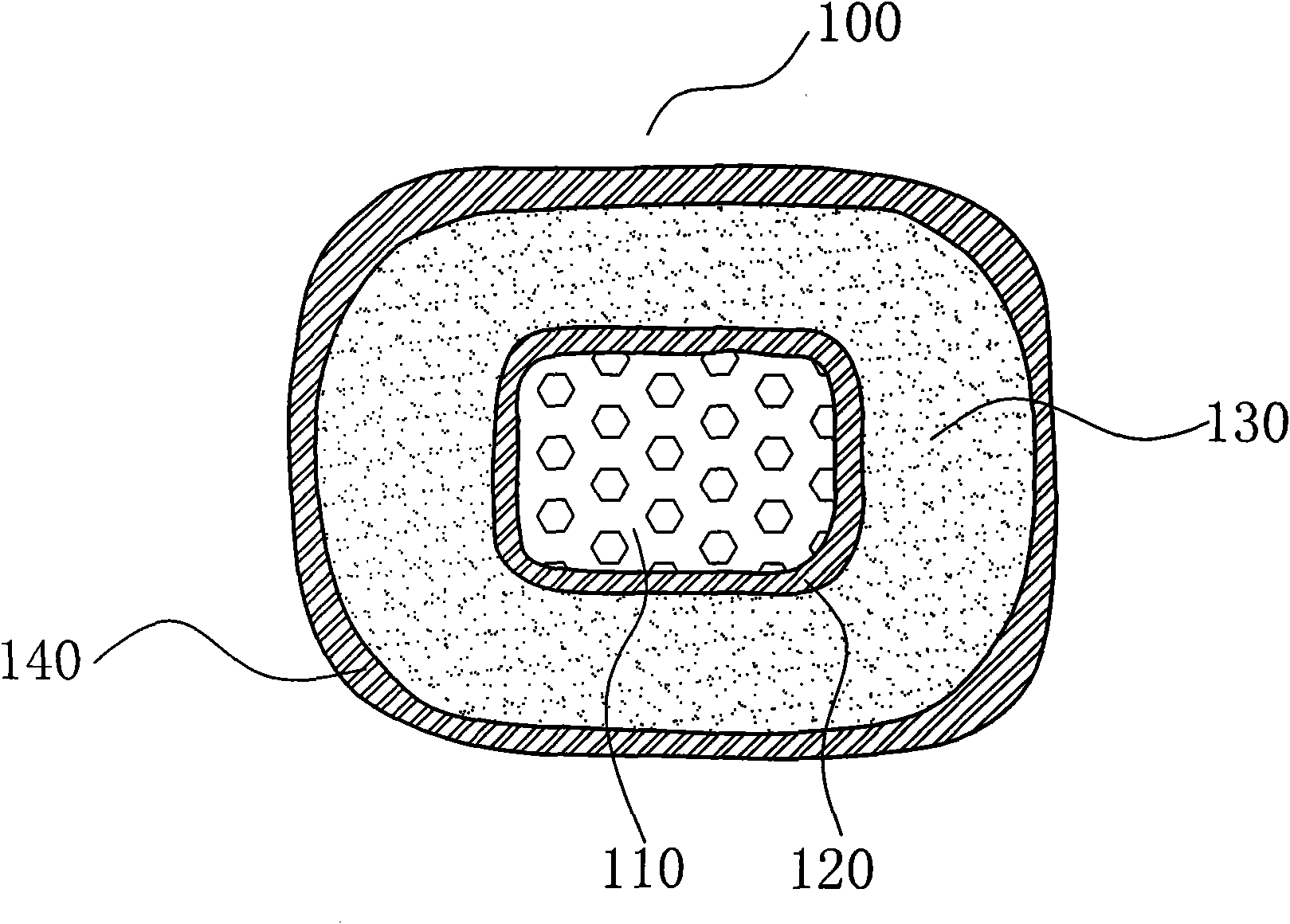

[0046] ginseng Figure 4 As shown, this figure shows a specific embodiment of the structure of a composite self-expanding package 100, the composite self-expanding package 100 includes a foam material A 110, and is arranged on the periphery of the foam material A110 The foam material A coating layer 120 of the foam material A coating layer 120, the foam material B 130 disposed on the periphery of the foam material A coating layer 120, and the foam material B coating layer 140 disposed on the periphery of the foam material B 130. In this embodiment, dilute sulfuric acid solution is selected for foaming substance A 100, and polyvinyl chloride plastic film is used for foaming substance A coating layer 120; corresponding to foaming substance A 100, dilute sulfuric acid solution is selected for use, and foaming substance B130 is selected CaCO 3 Powder, foam material B coating layer 140 is realized by polyethylene plastic film.

[0047] In this embodiment, the manufacturing method...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap