Blast-furnace tuyere maintenance vehicle

A technology for repairing vehicles and air vents, applied in the direction of air vents, etc., can solve the problems of inflexible alignment of air vents and single function, and achieve the effect of improving labor productivity and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the present invention.

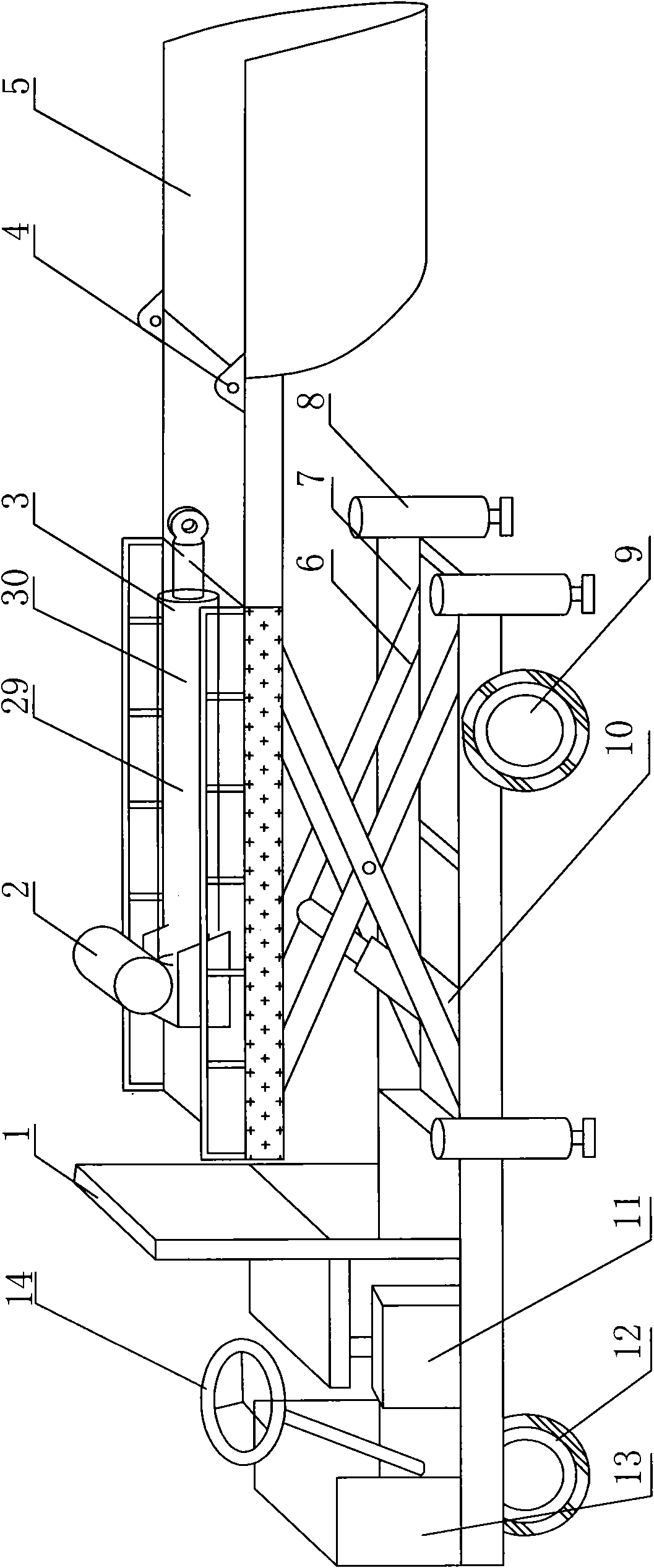

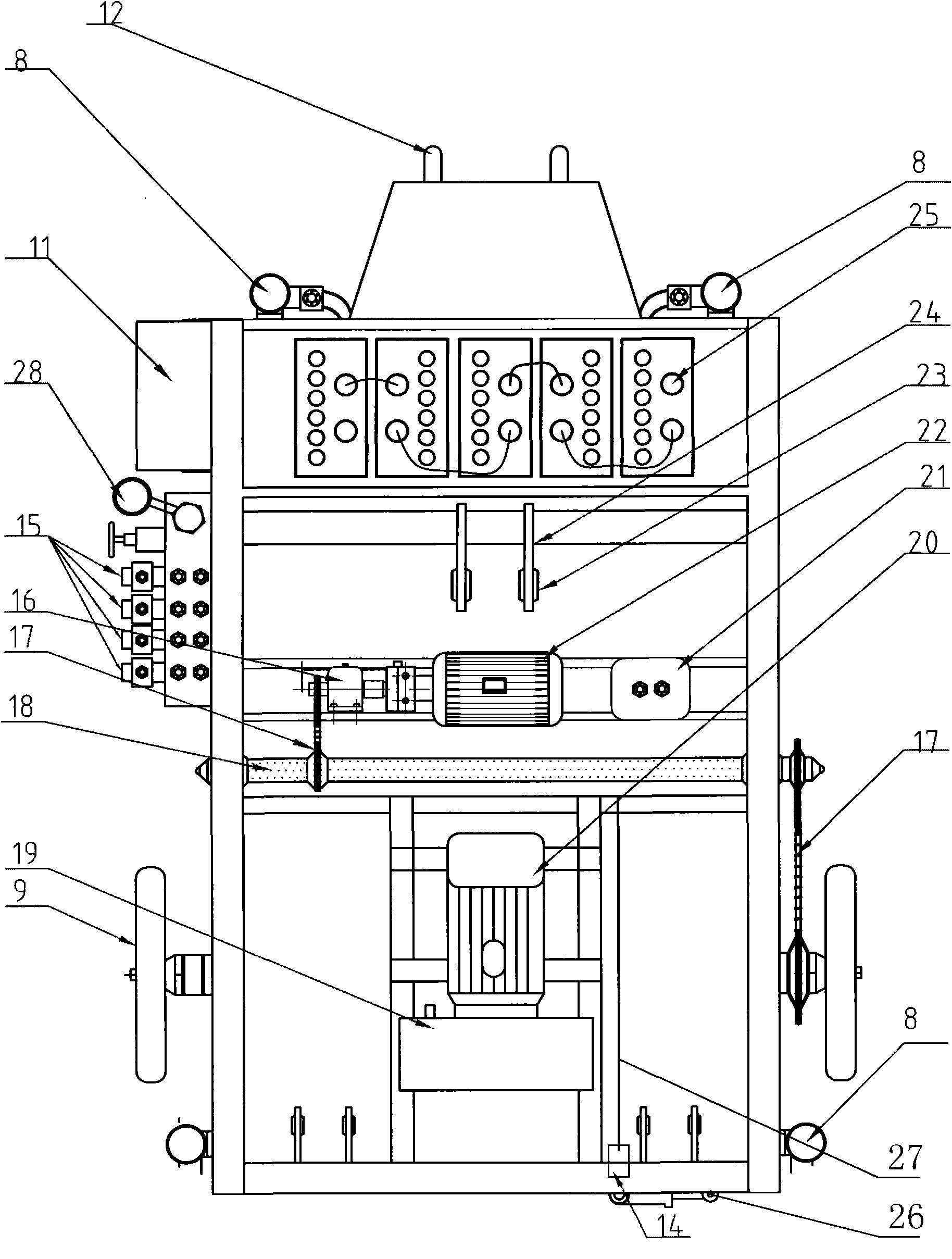

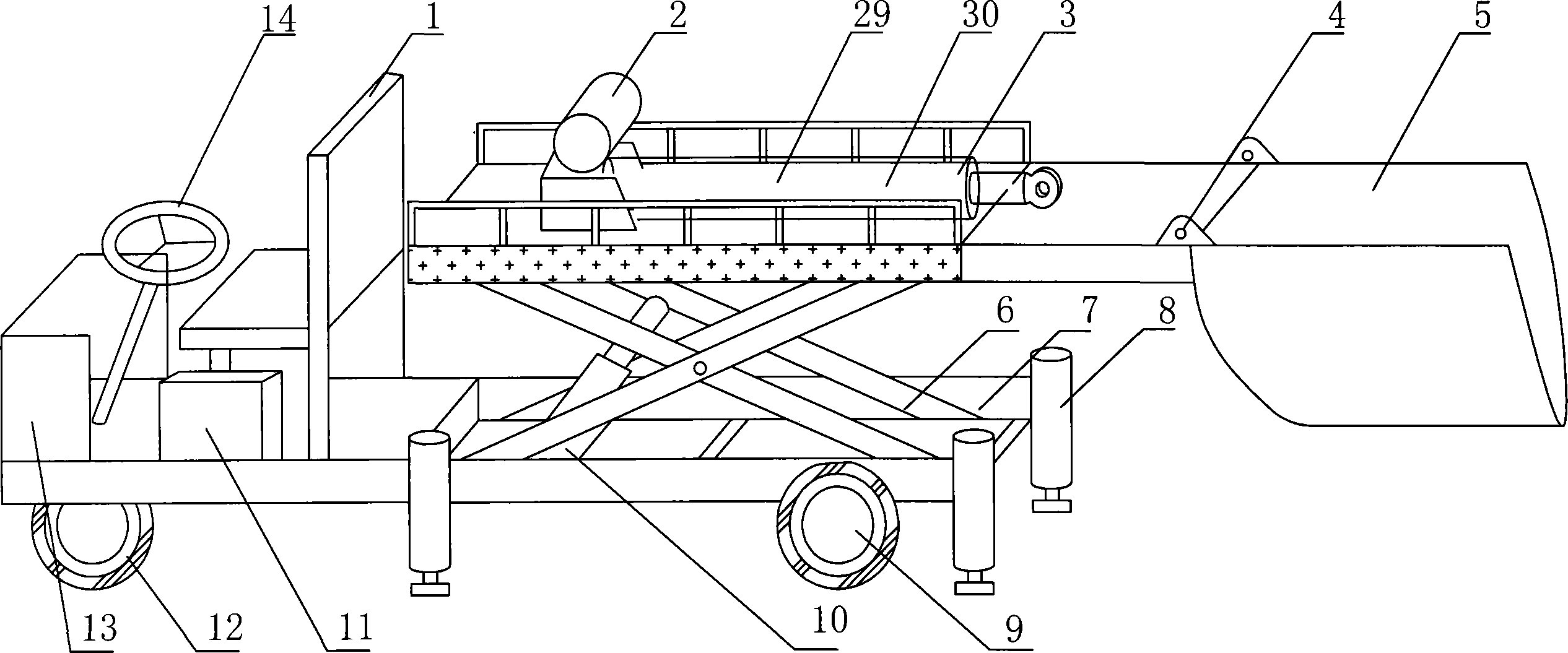

[0030] Such as figure 1 , 2 A blast furnace tuyere maintenance vehicle is shown, including a vehicle chassis 7, a power system, a platform 3, a lifting device, a lateral movement device, a propulsion cylinder, and a casing holding seat 5; the platform 3 is arranged above the vehicle chassis 7; The lifting device is installed on the chassis 7 and connected with the platform 3, and is used to control the movement of the platform 3 in the vertical direction; Movement; the cylinder body 29 of the propulsion cylinder is fixed above the platform 3, and the piston rod 30 connects the hook head and the push head; cover body.

[0031] Described vehicle chassis 7 comprises transmission mechanism, traveling mechanism, steering mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com