Building template and building combined template suitable for quick assembly

A technology for building formwork and combined formwork, which is applied in construction, building structure, formwork/formwork components, etc., can solve problems such as low firmness and inability to achieve rapid assembly, reduce wood waste, facilitate rapid assembly, and improve appearance. Smooth and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

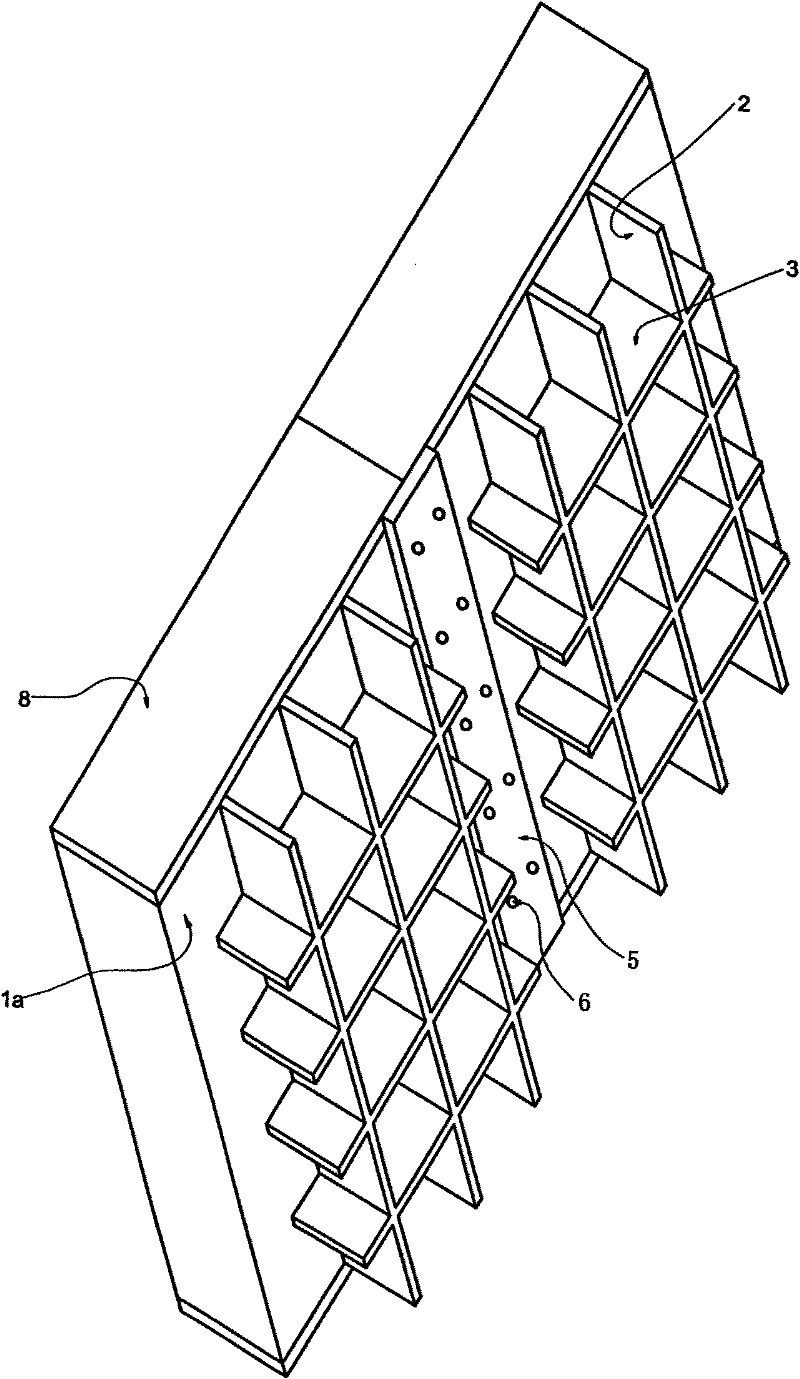

[0050] Embodiment five: see Figure 5 , the numbers are the same as those in Embodiment 1, and the meanings are the same, and the same parts will not be repeated. The difference is that a transverse reinforcing rib 3 is also provided on the longitudinal reinforcing rib 2 .

[0051] Embodiment six, seven: see respectively Figure 7 , Figure 8 , the numbers are the same as in Embodiment 1, and the meanings are the same, and the same parts will not be repeated. The difference is that the solid plane plate is set in a 90° corner shape to suit the combination of corners.

Embodiment 8

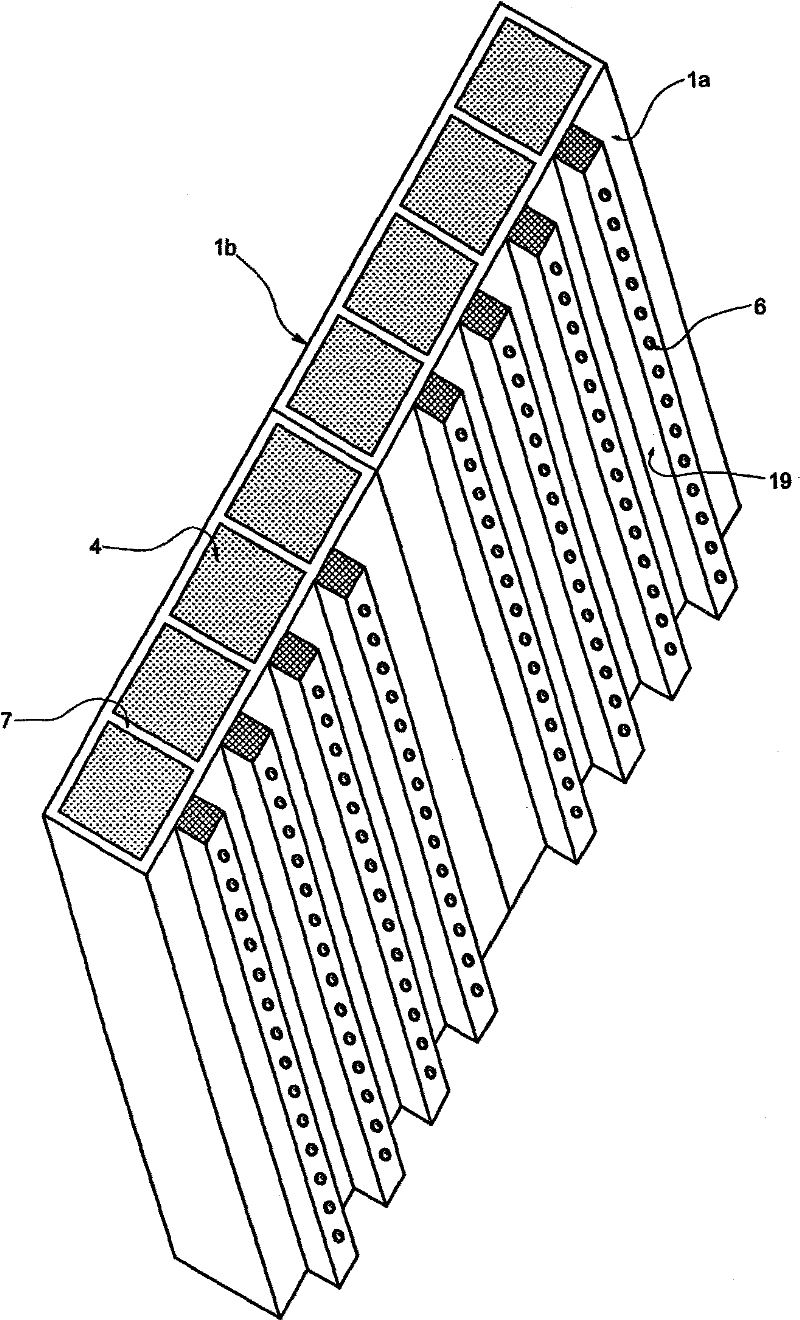

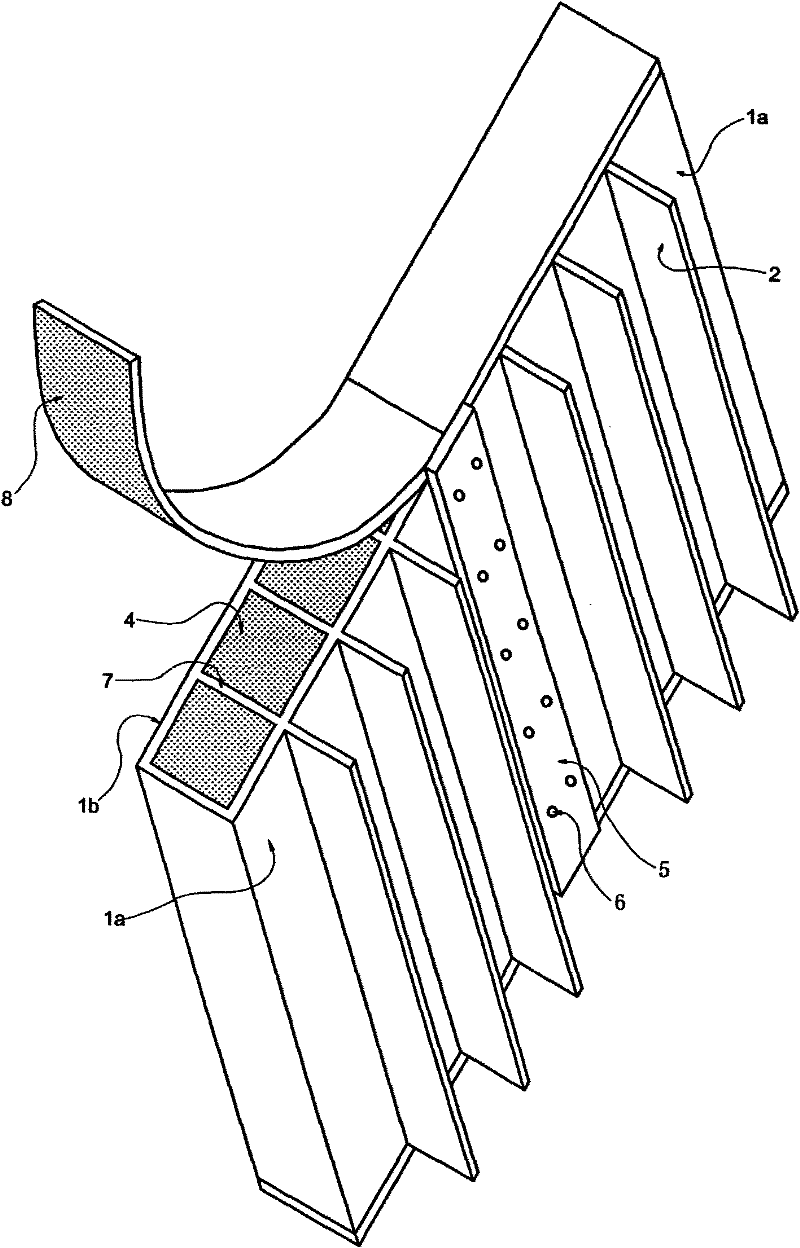

[0052] Embodiment eight, see Image 6 , Figure 7 , Figure 9 , the numbering is the same as in Embodiment 1, and the meaning is the same, and the same parts will not be repeated, and the difference is: the Image 6 , Figure 7 One of the combinations of templates.

Embodiment 9

[0053] Embodiment nine, see Figure 11 , the numbering is the same as in Embodiment 1, the meaning is the same, the same parts will not be repeated, and the difference is: an arc-shaped support plate 7' is fixed in the cavity of the hollow planar formwork.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com