Full-automatic walling machine

A fully automatic, wall-building technology, applied in construction, building structure, building material processing, etc., can solve the problems of time-consuming, labor-intensive, single-use function, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

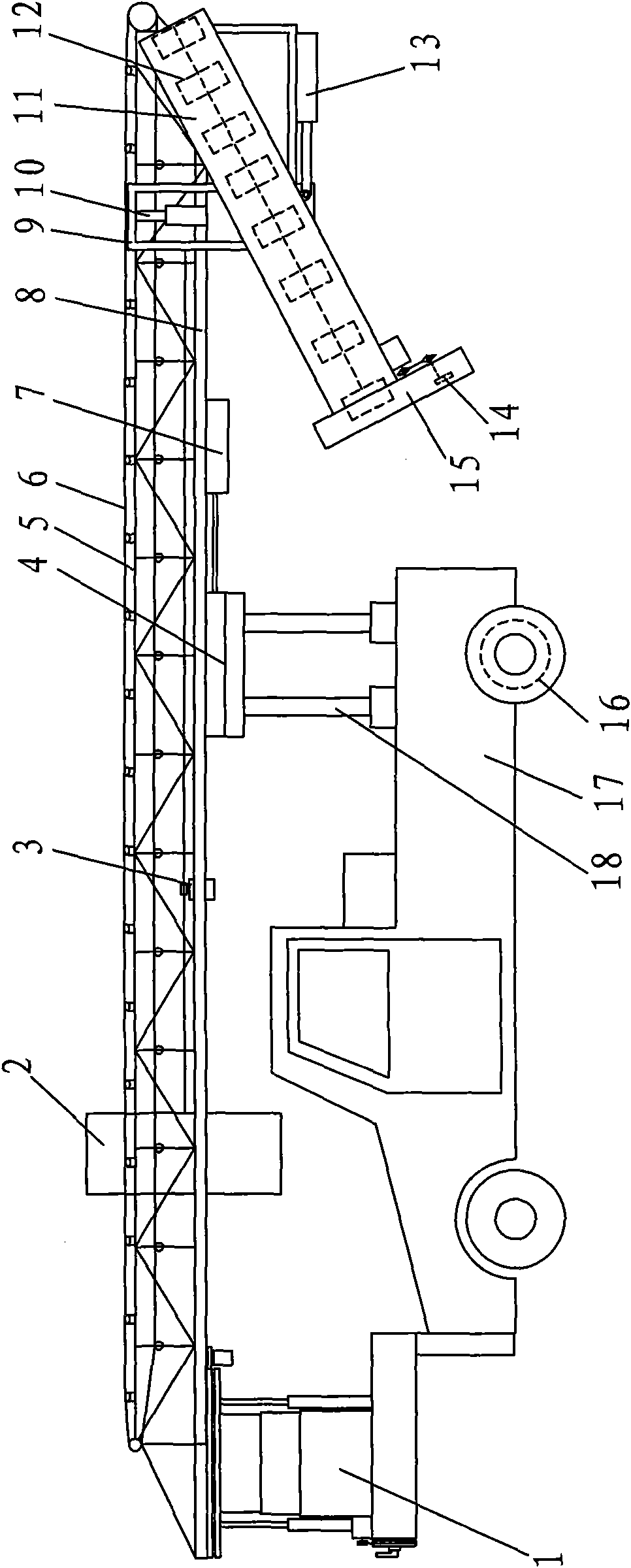

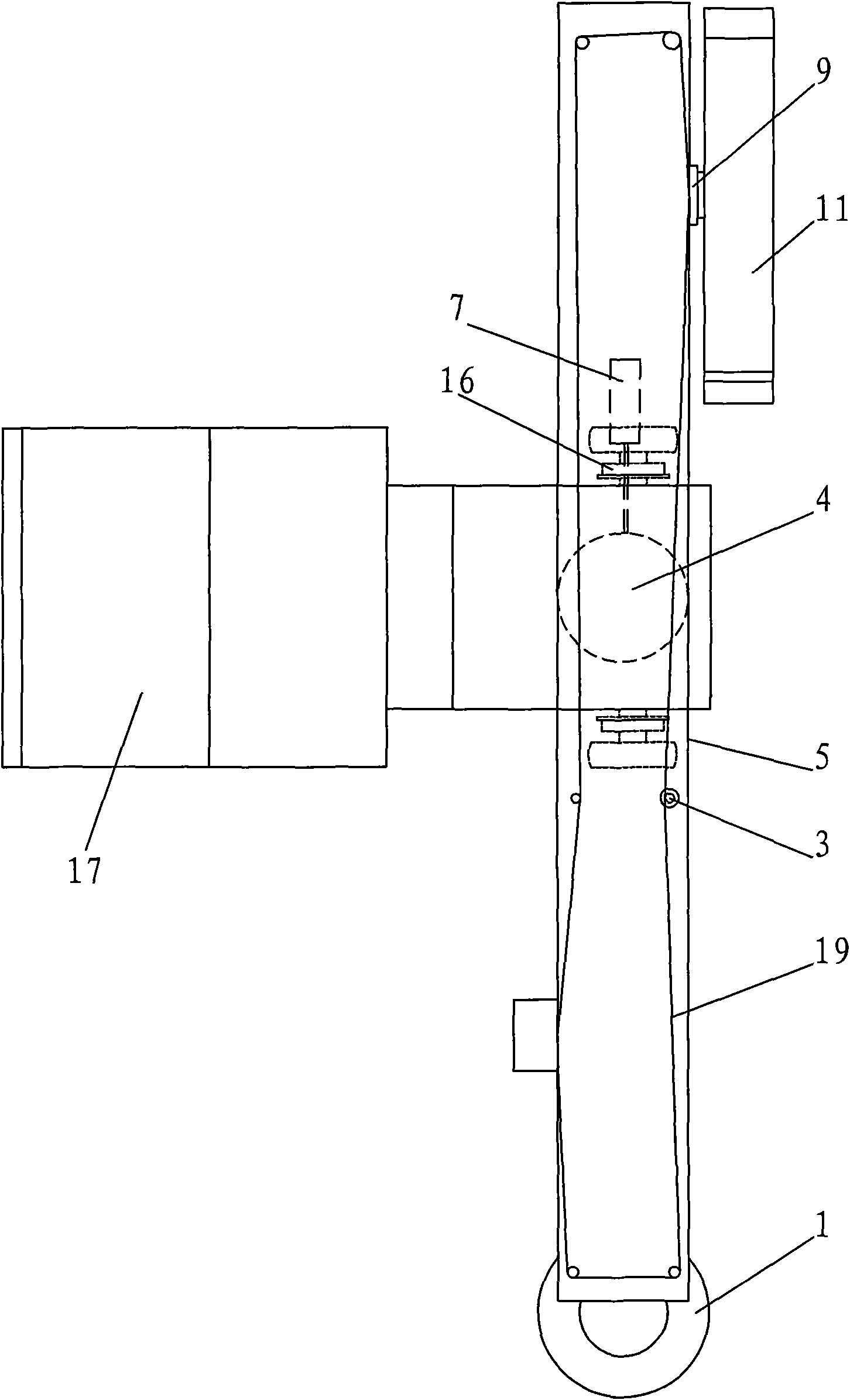

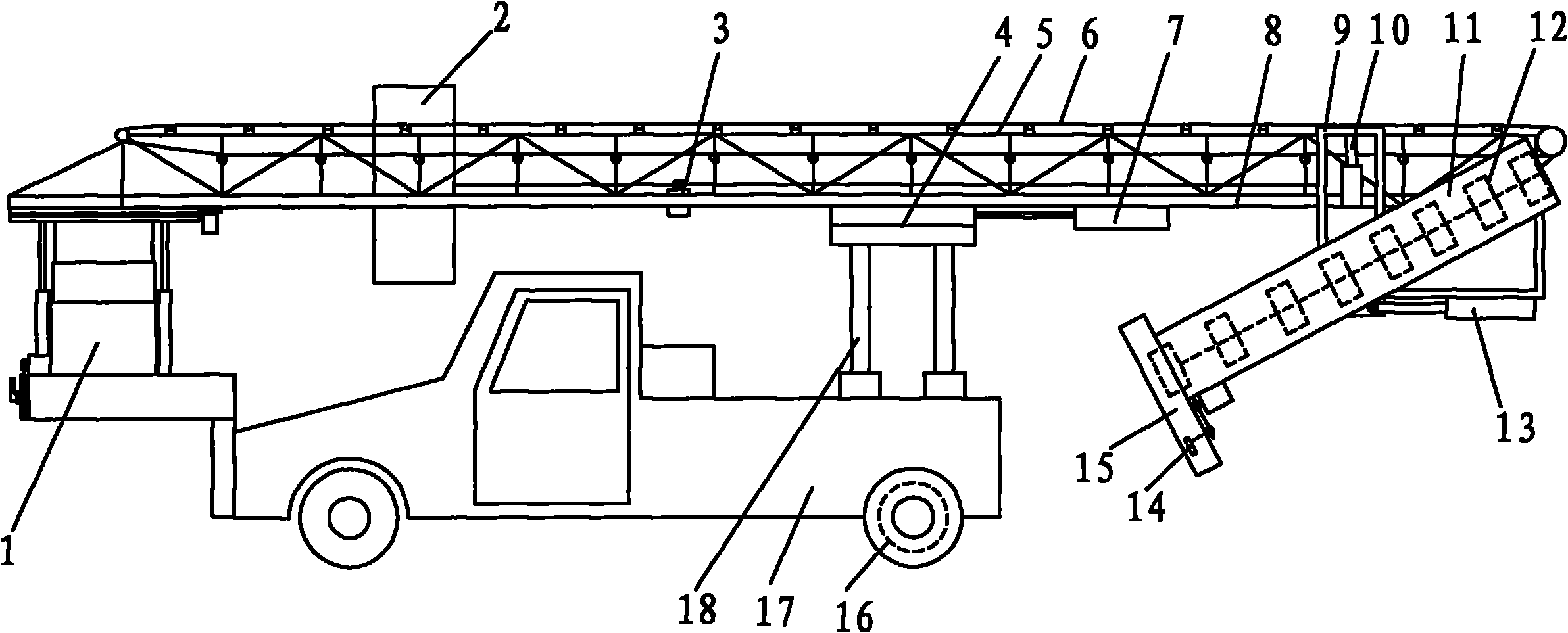

[0010] A fully automatic wall building machine, such as figure 1 , figure 2 Shown, comprise running gear 17 and horizontal conveyer belt device 5, running gear 17 can be converted into by existing truck chassis or adopt simple and simple train chassis to be converted into, wherein it is preferred scheme to adopt truck chassis, so that the present invention can Long-distance high-speed driving on the road, so as to obtain relatively high mobility.

[0011] The rear portion of running gear 17 is vertically provided with hydraulic lifting device 18, and the top of hydraulic lifting device 18 is provided with horizontal turntable 4, and said horizontal conveyor belt device 5 is installed on the horizontal turntable 4. During work, the hydraulic lifting device 18 can change the height position of the horizontal conveyor belt device 5, and the horizontal conveyor belt device 5 can be rotated by the horizontal turntable 4, so as to adjust the working angle and position.

[0012] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com