Coal and gas outburst forecasting method

A gas outburst and coal-rock mass technology, which is applied in the field of coal and gas outburst prediction, can solve the problems of large influence of human factors and influence on coal and gas prediction results, and achieve the effect of reducing engineering costs and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

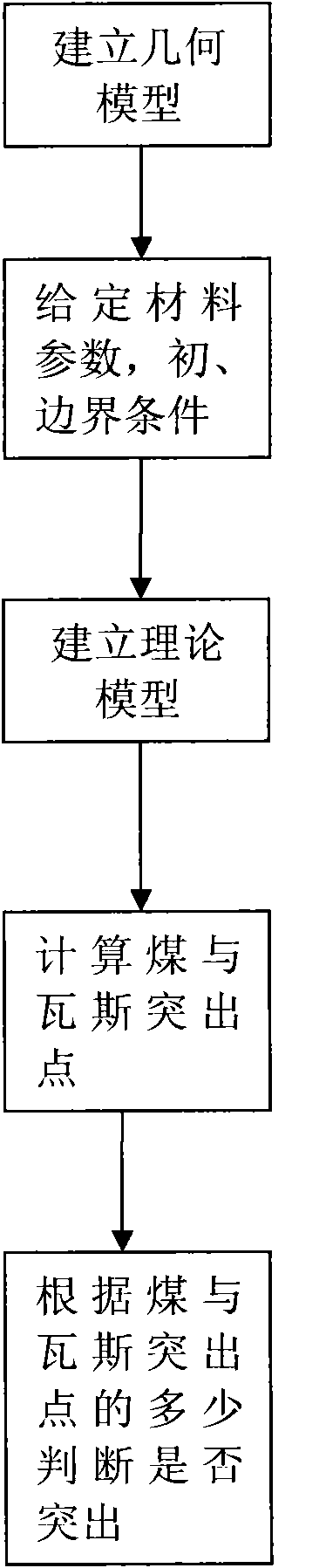

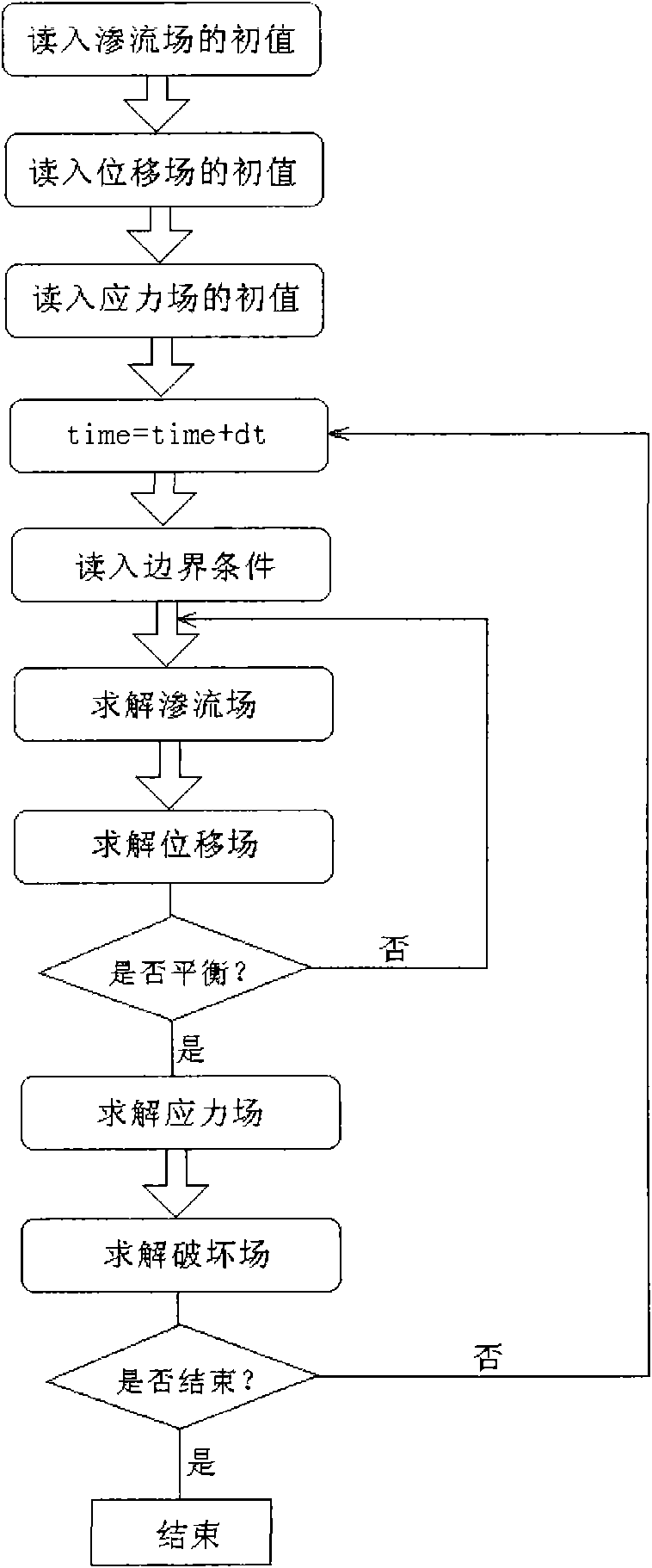

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: Steps for judging whether Jieshimen protrudes

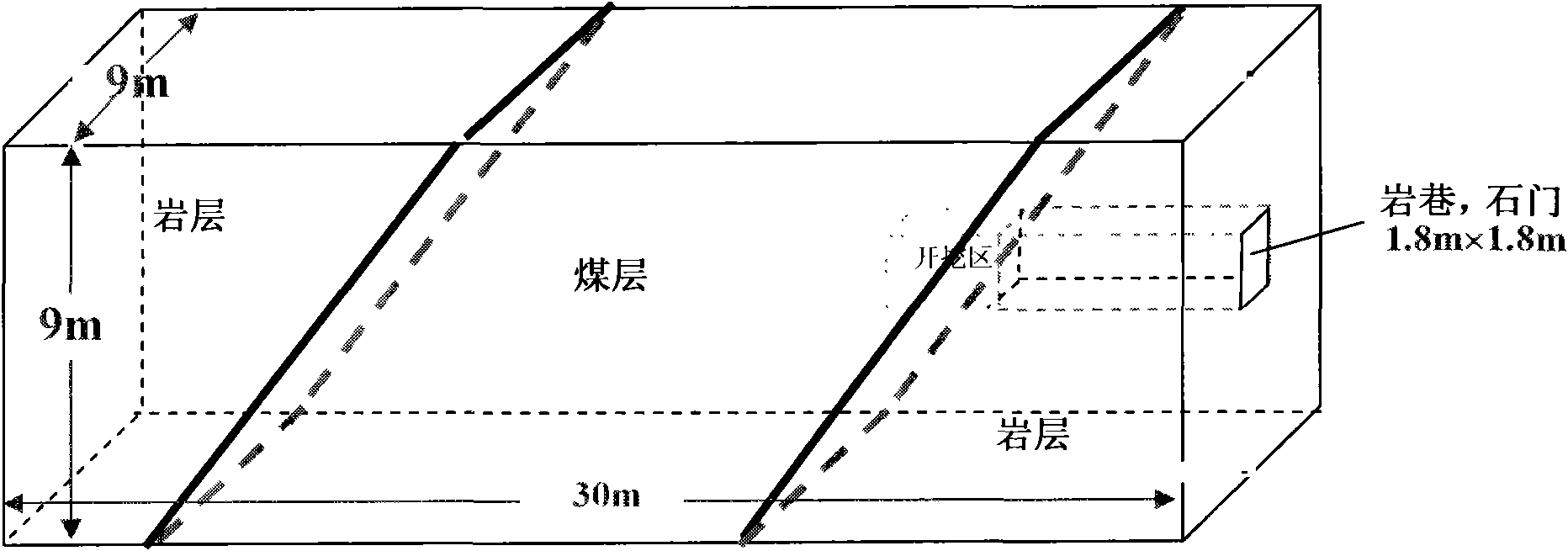

[0063] (1) Establish the geometric model of Jieshimen, the model and dimensions are as follows image 3 shown.

[0064] (2) The material parameters of the given coal seam and rock formation.

[0065] The average elastic modulus of coal mass E=1.0×10 9 Pa, minimum elastic modulus of coal body E=1.0×10 8 Pa

[0066] Rock elastic modulus mean E=1.0×10 10 Pa, minimum value of elastic modulus of rock E=1.0×10 9 Pa

[0067] Tensile strength mean σ t =0.6×10 6 Pa, minimum tensile strength σ t =0.6×10 5 Pa,

[0068] Average shear strength σ t =2.0×10 7 Pa, the minimum shear strength σ t =2.0×10 6 Pa

[0069] Inhomogeneity coefficient of elastic modulus and strength m=10

[0070] Coal Poisson's ratio v=0.25, rock Poisson's ratio v=0.25

[0071] permeability coefficient k 0 =7.62×10 -15 m 2 ,

[0072] Gas density ρ a =0.8kg / m 3 .

[0073] (3) Given the initial value and boundary conditions.

...

Embodiment 2

[0077] Embodiment 2: Steps for judging whether the blasting tunneling of the coal roadway is outburst

[0078] The difference between blasting tunneling in coal lanes and unraveling stone gates is that coal and gas outbursts are different in calculation parameters and initial boundary conditions, and the rest are the same as in implementation 1.

[0079] The calculation parameters of the numerical simulation of blasting tunneling in coal roadway are:

[0080] The average elastic modulus of coal mass E=1.0×10 9 Pa, minimum elastic modulus of coal body E=1.0×10 8 Pa

[0081] Rock elastic modulus mean E=1.0×10 10 Pa, minimum value of elastic modulus of rock E=1.0×10 9 Pa

[0082] Tensile strength mean σ t =0.8×10 6 Pa, minimum tensile strength σ t =0.8×10 5 Pa,

[0083] Average shear strength σ t =3.0×10 7 Pa, the minimum shear strength σ t =3.0×10 6 Pa

[0084] Inhomogeneity coefficient of elastic modulus and strength m=10, permeability coefficient k 0 =7.62×10 ...

Embodiment 3

[0088] Example 3: One-dimensional gas outburst and constant advancement

[0089] During the period from 1985 to 1996, the Institute of Mechanics of the Chinese Academy of Sciences made a large number of one-dimensional coal and gas outburst simulation experimental devices such as Figure 6 Shown, understand the basic phenomenon of coal and gas outburst. In the experiment, the coal sample was pressed into a round tube, and the round tube was separated into a high-pressure gas area and an ordinary atmospheric pressure area by aluminum foil. When the aluminum foil is broken, observe the protrusion of the coal sample.

[0090] The difference between this embodiment and Embodiment 1 lies in that the established geometric model, calculation parameters, and initial and boundary conditions are different, and the rest of the steps are the same as in Embodiment 1.

[0091] The geometric model for the numerical simulation of one-dimensional gas outburst constant propulsion is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com