Limit filling device used for cryogenic liquid container and cryogenic liquid container

A low-temperature liquid and container technology, applied in the field of limit filling device and low-temperature liquid container, can solve the problems of low-temperature steam and liquid discharge, environmental pollution, low-temperature liquid waste, etc., to achieve safe filling process, avoid environmental pollution, and save energy energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

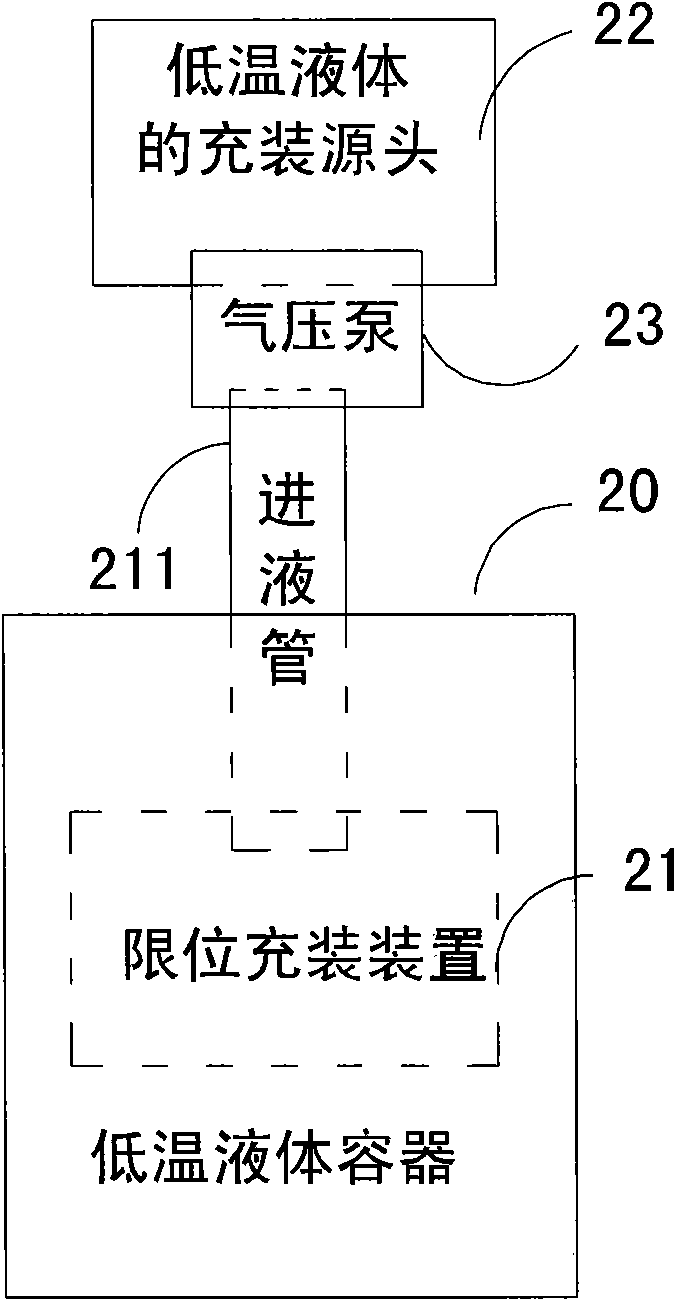

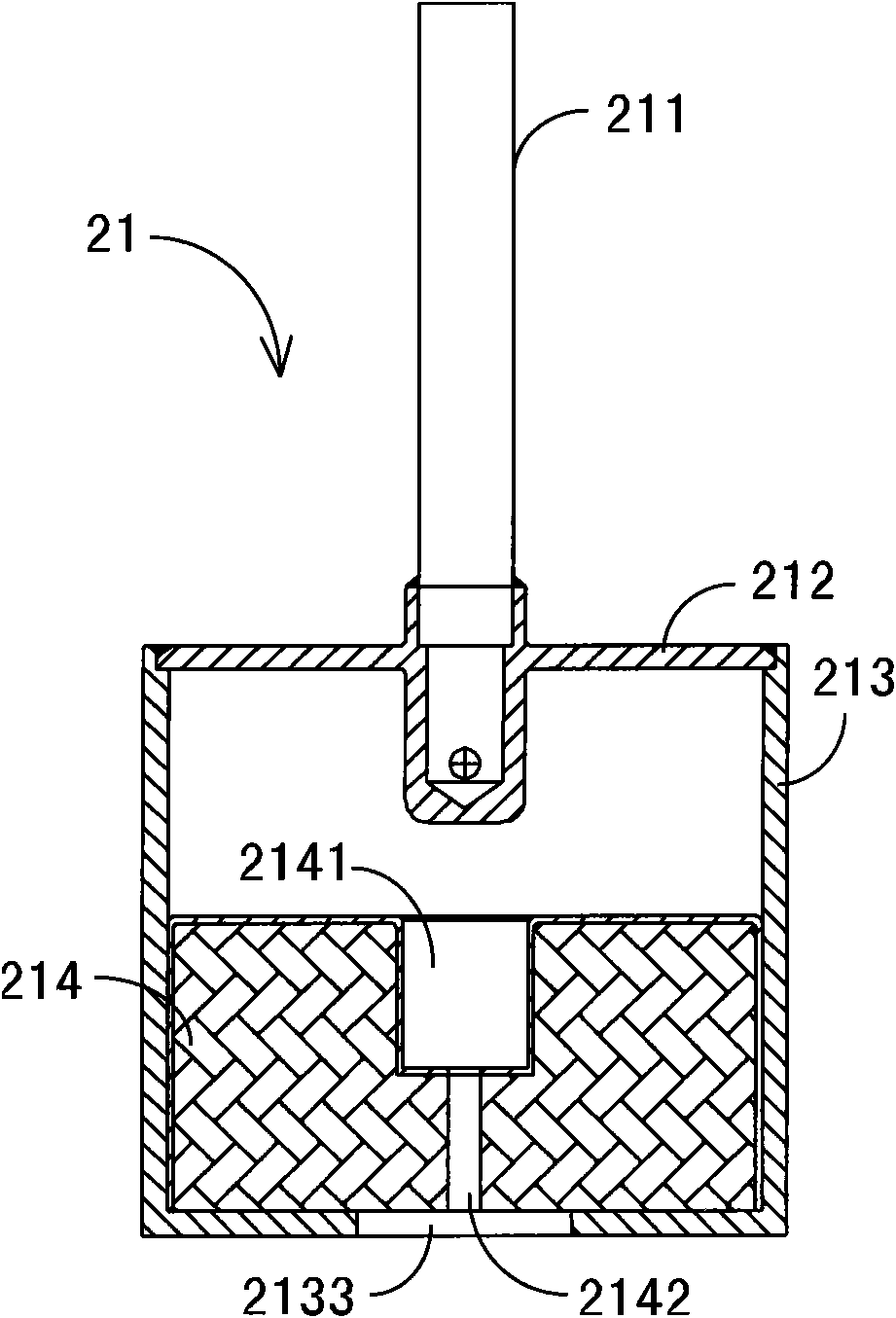

[0025] figure 2 It is a schematic diagram of the filling structure of the cryogenic liquid container of the present invention. The cryogenic liquid container 20 includes a liquid inlet pipe 211 and a limit filling device 21 arranged in the cryogenic liquid container 20. The limit filling device 21 is used to achieve low temperature The non-destructive filling of the liquid in the cryogenic liquid container 20. One end of the liquid inlet pipe 211 is inserted into the cryogenic liquid container 20, and the other end is connected to a pneumatic pump 23. The pneumatic pump 23 is set at the fil...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap