Light guide plate

A technology of light guide plate and acrylic resin, which is applied in the field of light guide plate, can solve the problems of insufficient light transmittance and insufficient operation characteristics of light guide plate, and achieve excellent processability and operation characteristics, excellent light transmittance, and high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8 and comparative example 3

[0123]

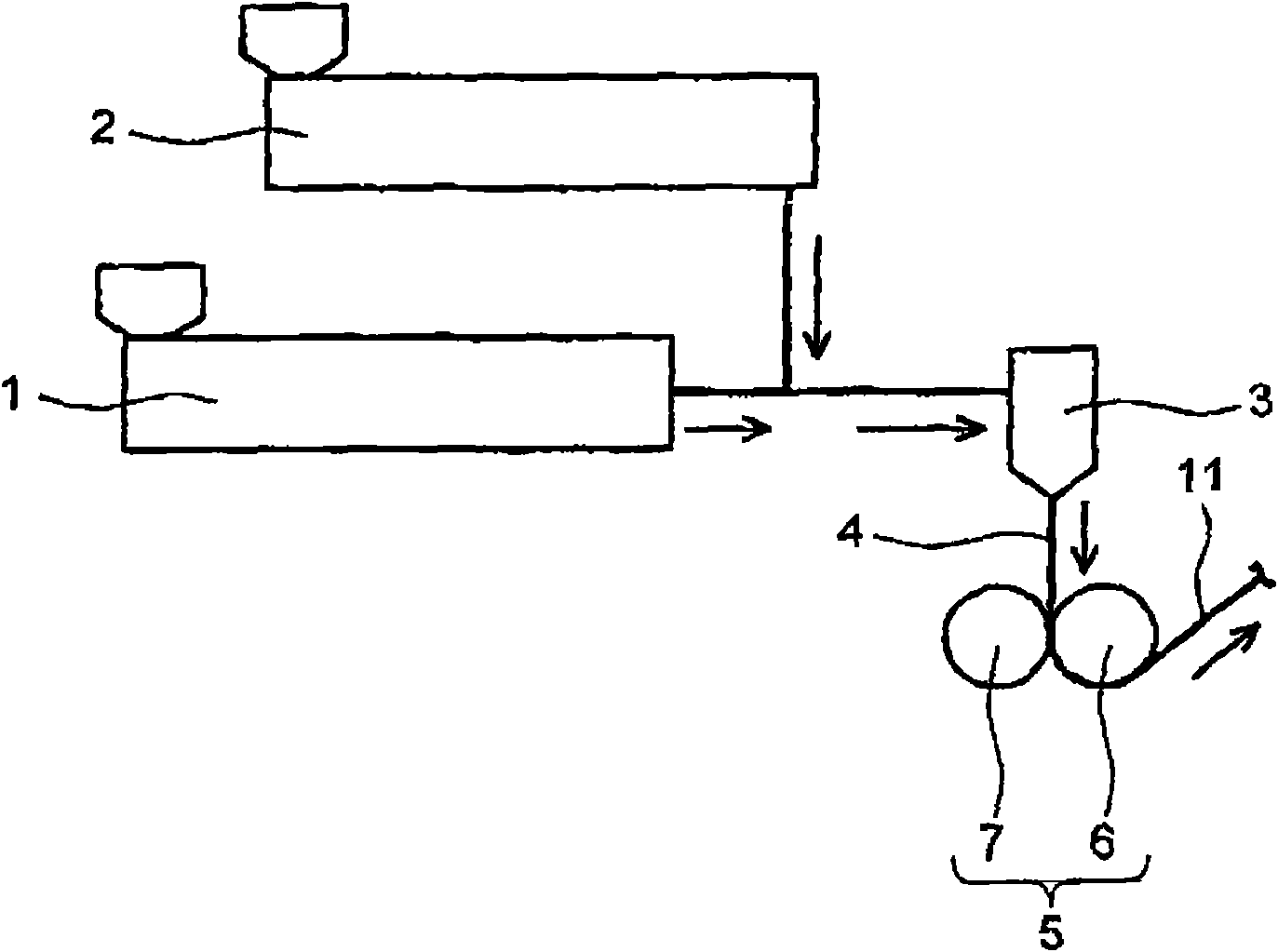

[0124] As the resin layer A, resins of the types shown in Table 1 were melt-kneaded with the extruder 1 and supplied to the feed block. On the other hand, as the resin layer B, resins of the types shown in Table 1 were melt-kneaded by the extruder 2 and supplied to the feed block. Coextrusion molding was performed so that the resin layer A supplied from the extruder 1 to the feedblock was an intermediate layer, and the resin layer B supplied from the extruder 2 to the feedblock was both surface layers.

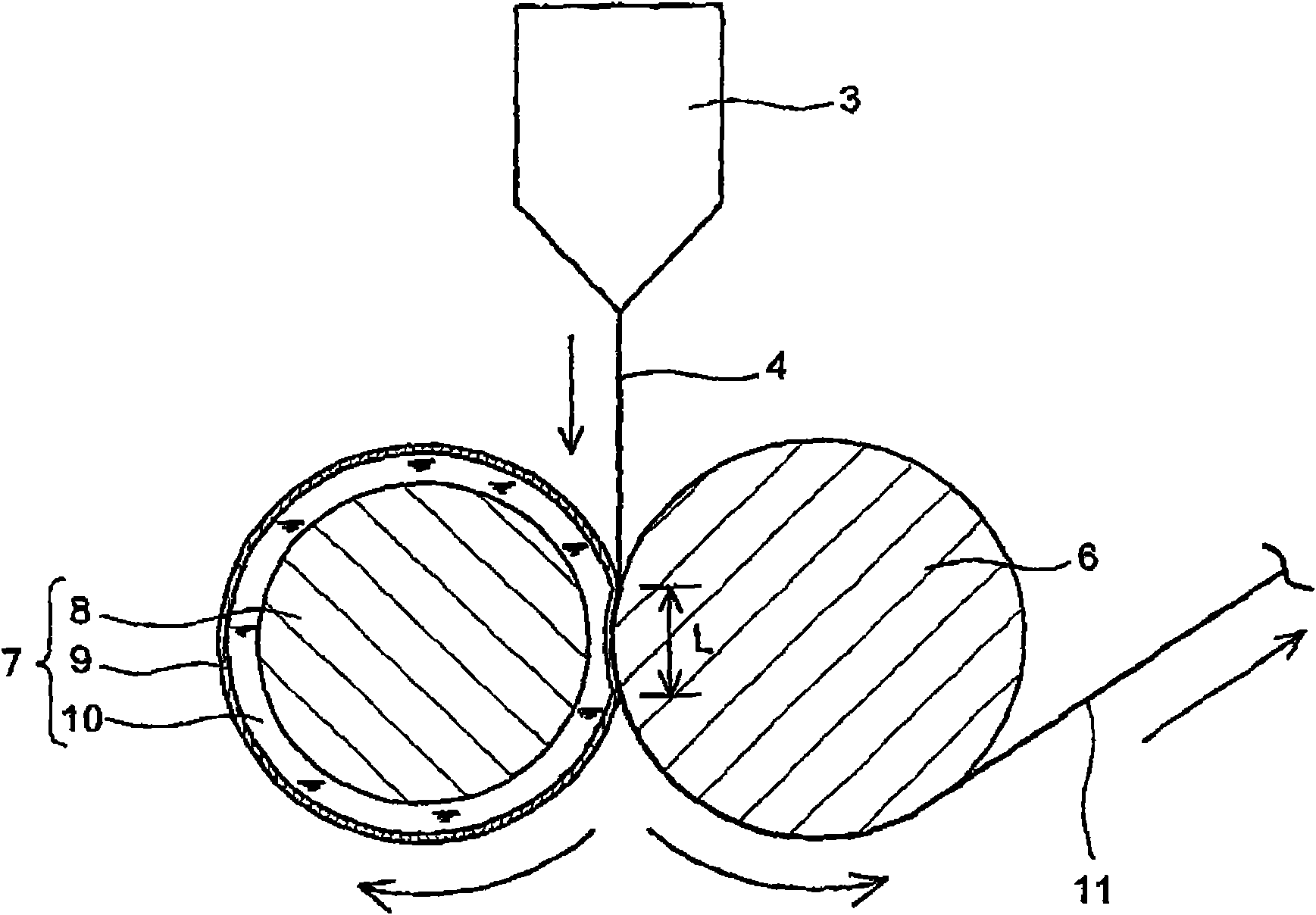

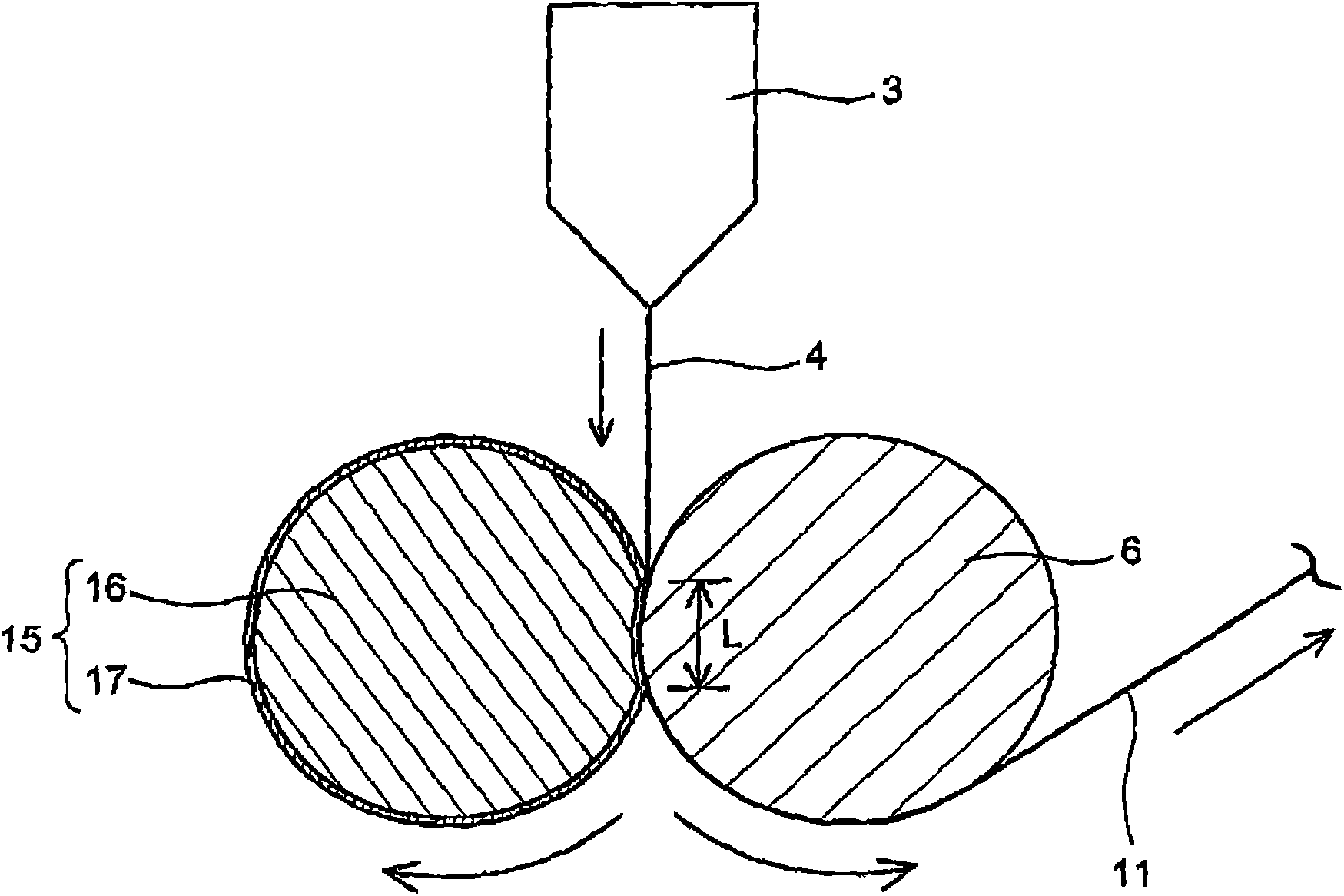

[0125] Then, the molten resin 4 extruded from the die 3 was formed into a film while being sandwiched between the No. 1 roll and the No. 2 roll of the roll configuration shown in Table 1, and a light guide plate having a three-layer structure having the thickness shown in Table 1 was obtained. . In addition, the surface temperature of the No. 1 roll was 130°C, and the surface temperature of the No. 2 roll was 140°C. These temperatures are actual measured values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com