Method for supporting static test for light-aircraft fore fuselages

A static test and light aircraft technology, which is applied in the direction of aircraft component testing, aircraft parts, machine/structural component testing, etc., can solve the problems of high cost, large influence of test results, complicated operation, etc., and achieve low cost and shortened test Cycle, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by specific embodiment the present invention is described in further detail:

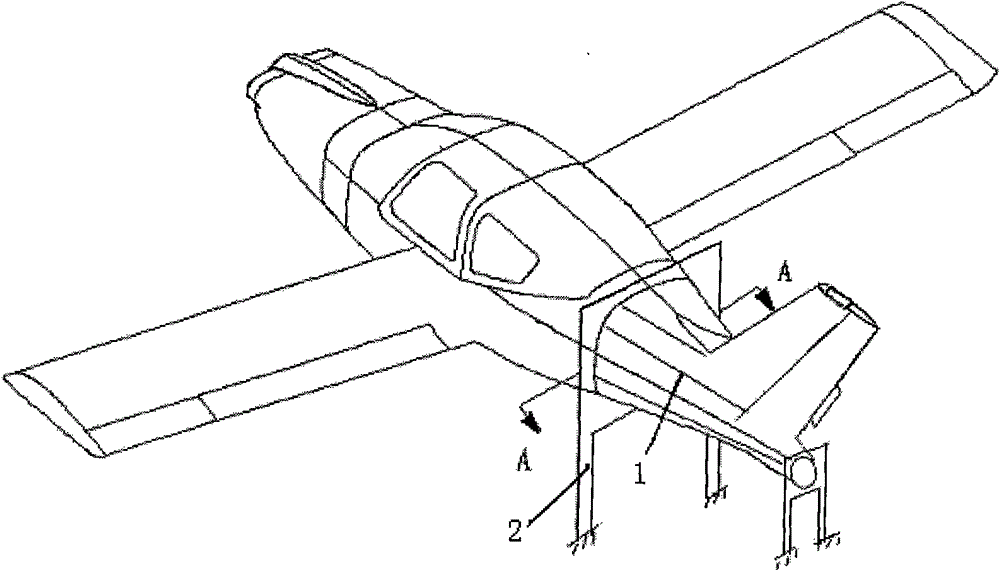

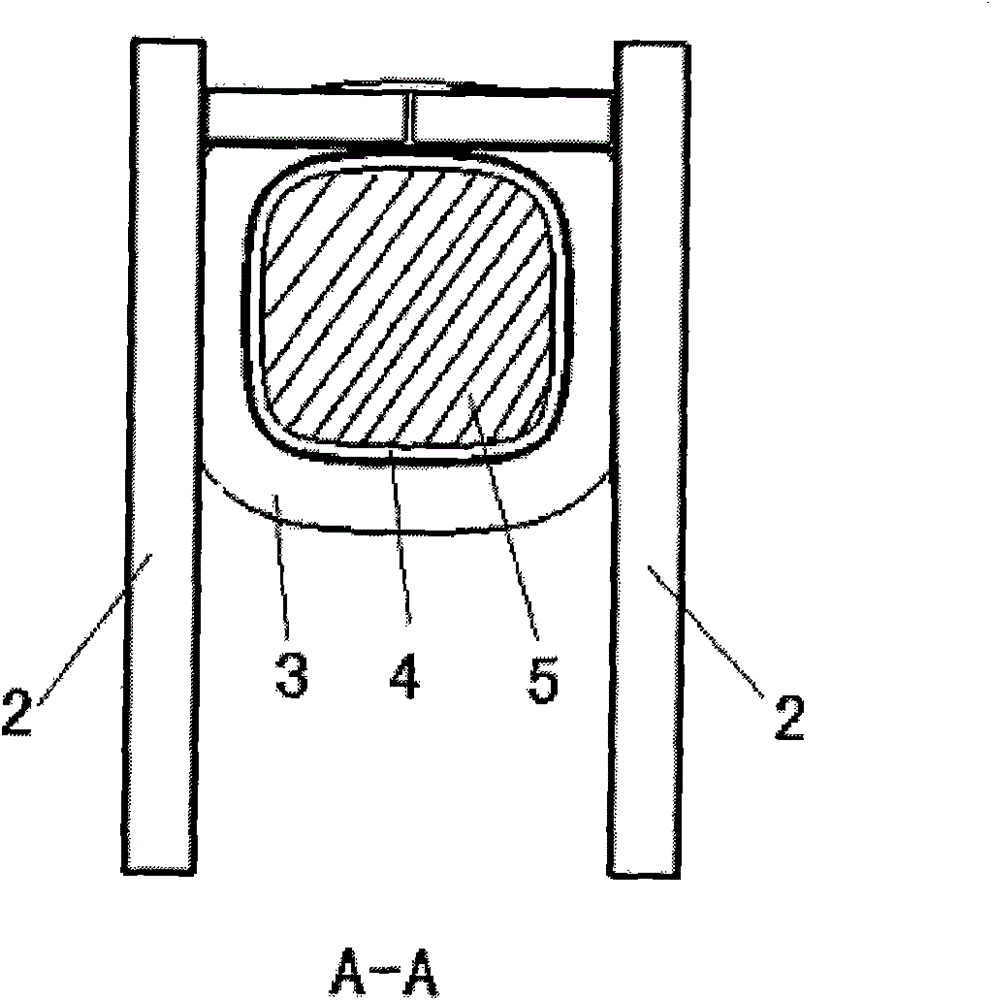

[0015] Please also see figure 1 with figure 2 ,in figure 1 It is a schematic diagram of the aircraft support method involved in the light aircraft front fuselage static strength test support method of the present invention, figure 2 yes figure 1 A-A cutaway view. In this embodiment, the light aircraft is the Kitty Hawk-500, and its own structure has few vertical load-bearing parts and its rigidity is relatively weak. Therefore, when carrying out the static strength test to its front fuselage, the present invention is provided with two hoops 3 at the straight frame 4 of the rear fuselage of the aircraft, wherein, a hoop 3 is arranged on the rear between the wing and the flat tail of the aircraft. There are 4 places on the straight frame of the fuselage, and the clamp 3 is arranged as far away from the wing structure as possible under the premise of being able to bear the load of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com