Face-to-face photographing type coin inspection machine and coin inspection method

A technology for inspecting machines and coins, applied to coin inspection, handling coins or valuable banknotes, instruments, etc., can solve the problems of large space size, undetectable, complex structure, etc., to reduce volume, reduce space requirements, and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described below in conjunction with the accompanying drawings.

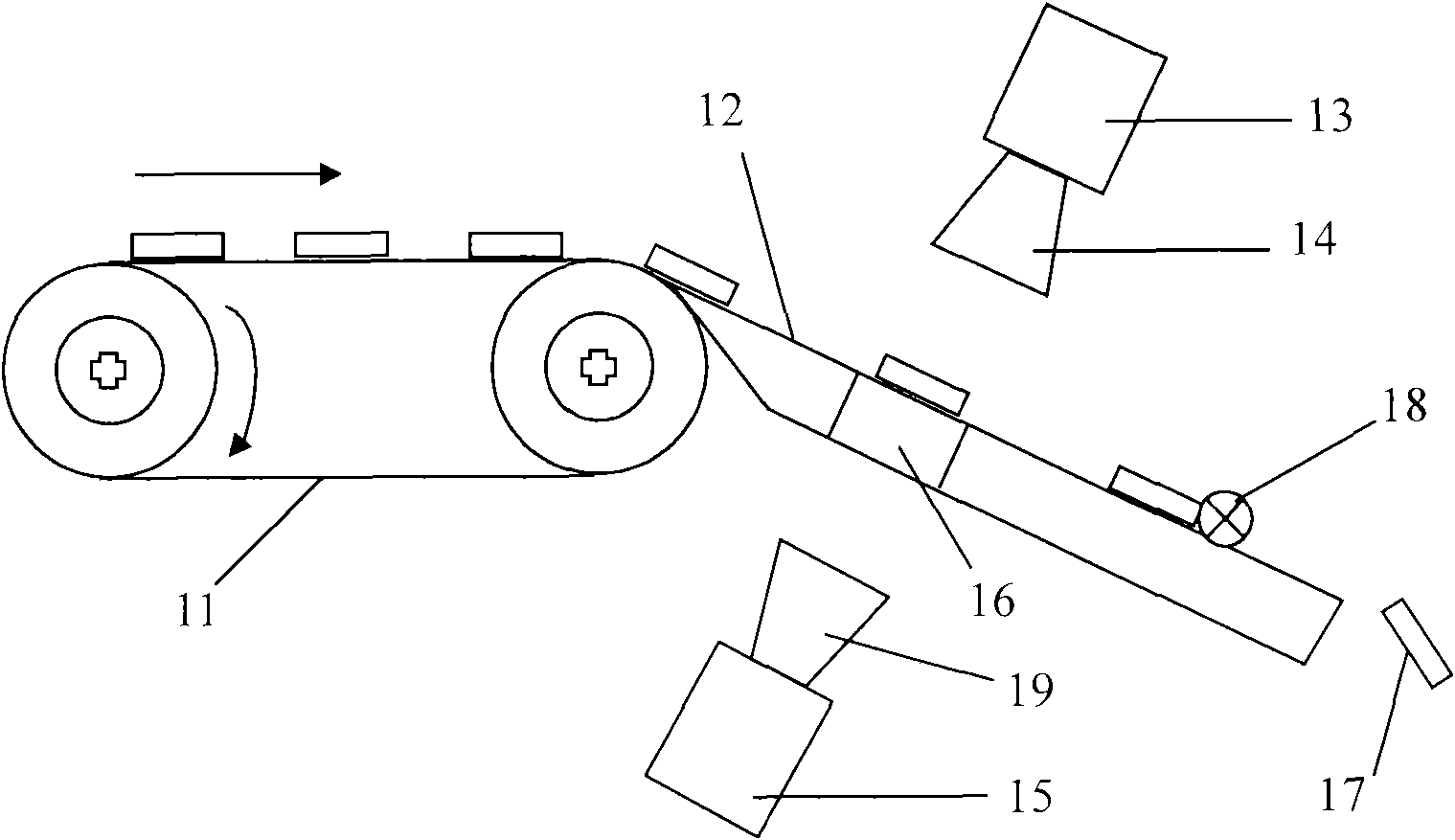

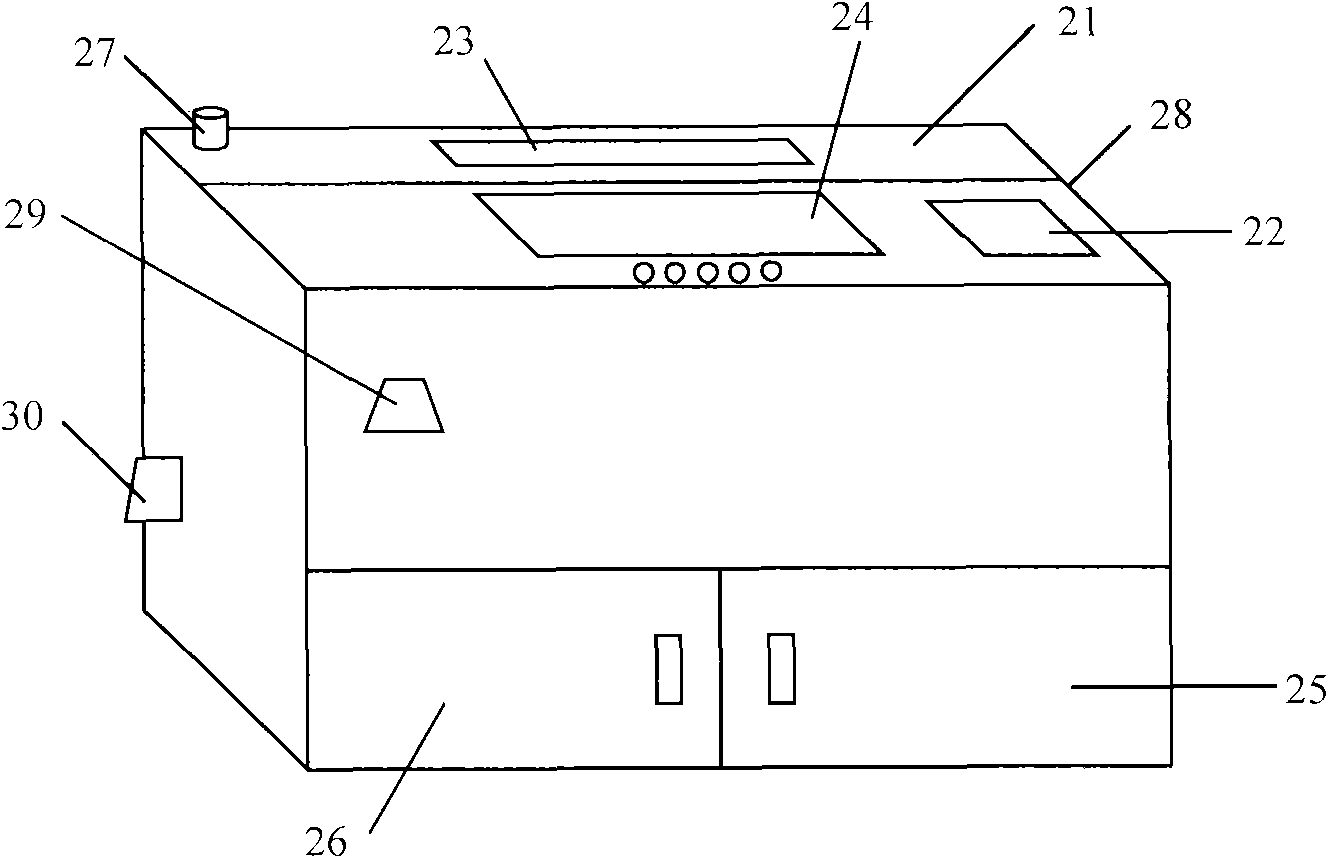

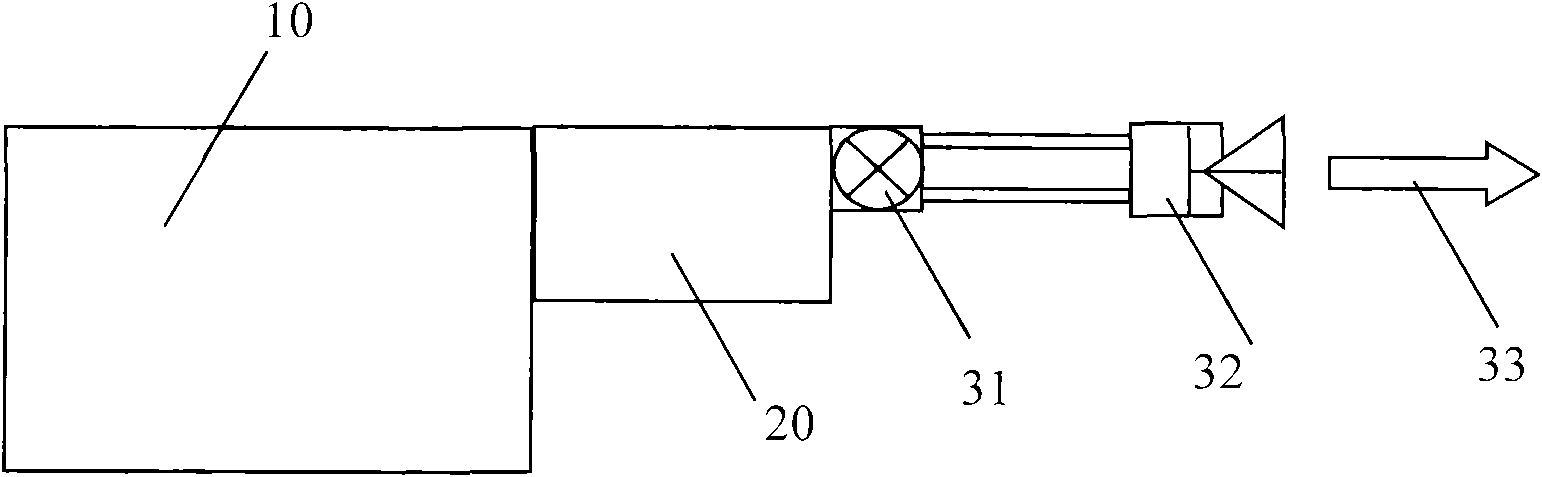

[0044] The structural principle diagram of the beat-to-beat coin inspection machine of the present invention is as follows figure 1As shown, a counter-beat coin inspection machine is used to perform quality and counter-print inspection on coin stamping images, including a conveyor belt 11, an inclined slide 12 and a counter-pat structure, and the inclined slide 12 is connected to the outlet end of the conveyor belt 11. The coins move along the conveying direction of the conveyor belt 11. In order to prevent the coins from shaking left and right on the conveyor belt, guide strips are arranged on the conveyor belt. After the coins pass through the guide strips on the conveyor belt, they are arranged in a row. After the coins are conveyed from the conveyor belt 11, they enter the inclined slideway 12. A transparent structure is provided on the inclined slideway 12 so that both th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com