Electromagnetic wire manufacturing method capable of preventing blackening of electromagnetic wires

A manufacturing method and technology of magnet wires, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of blackening and surface blackening of insulating tape magnet wires, and achieve the effect of preventing conductor oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

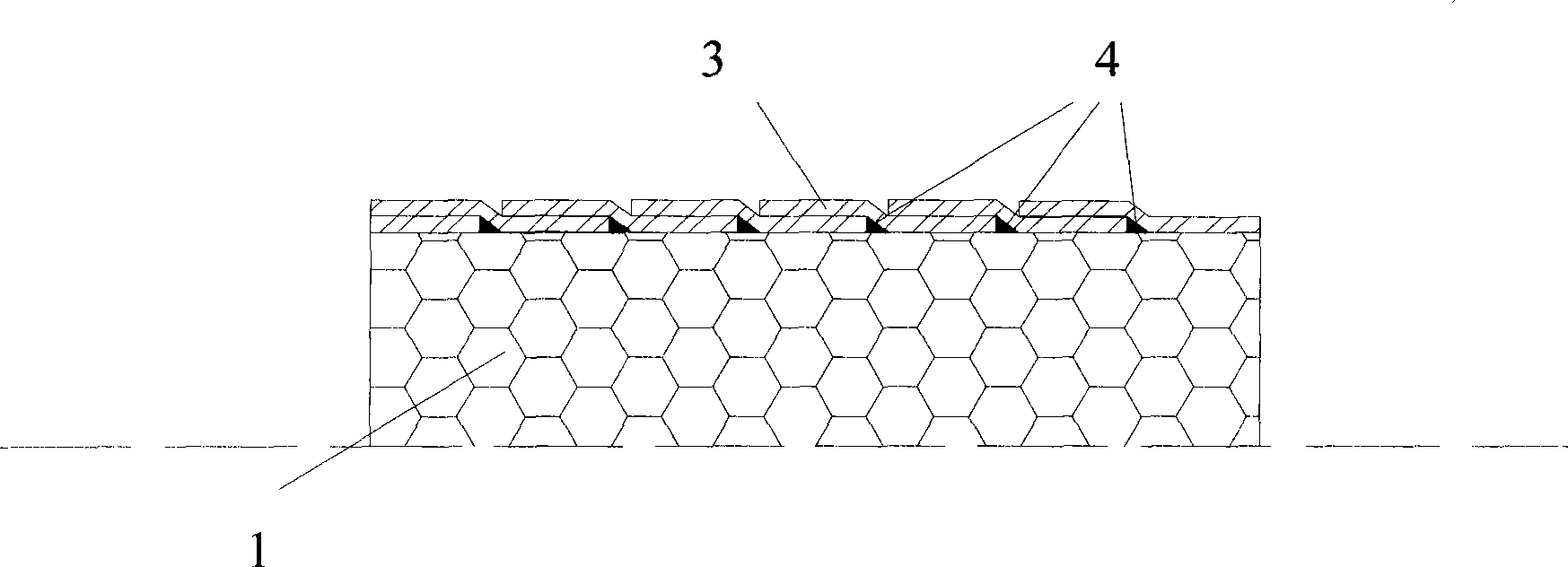

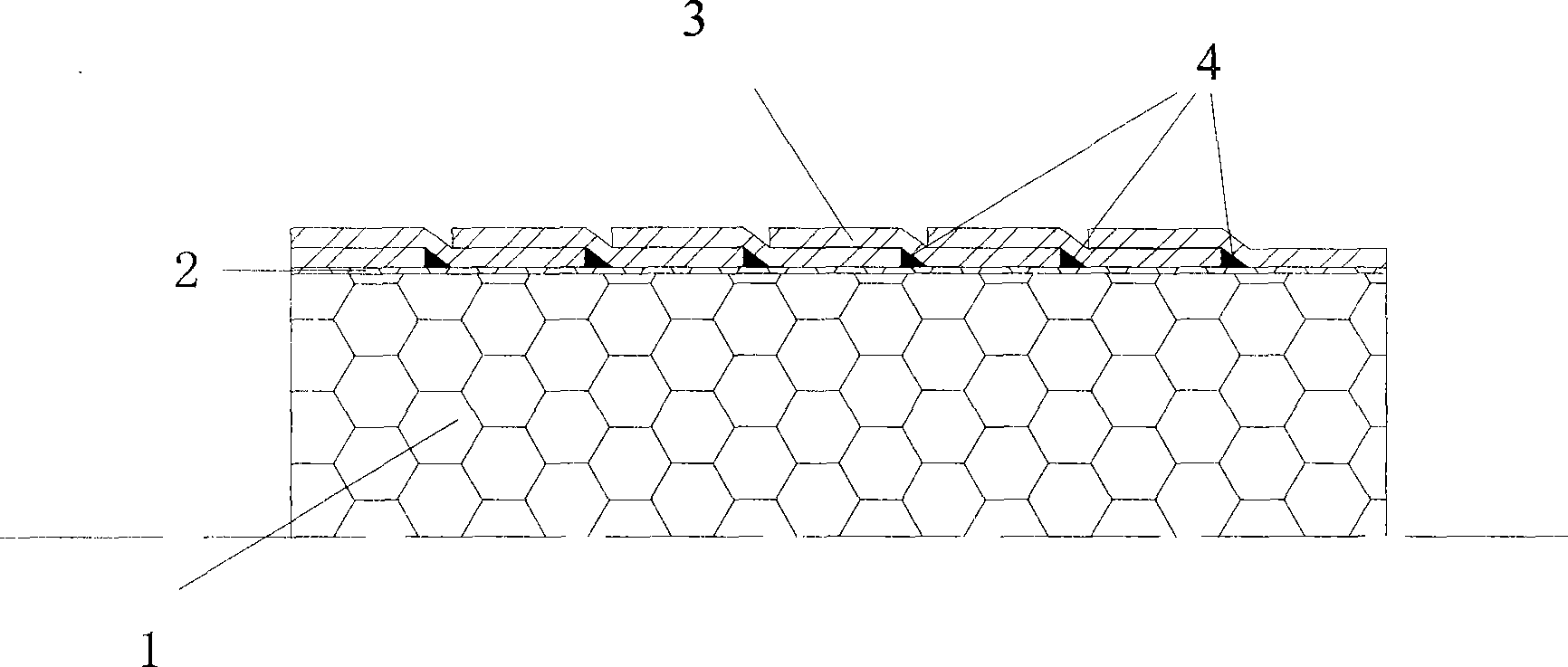

[0017] as attached figure 2 As shown, the present invention is an anti-blackening wrapping method for electromagnetic wires, in which an insulating coating 2 made of insulating material is painted on the surface of the existing electromagnetic wires 1, so that the electromagnetic wires are fully wrapped when wrapped. It is isolated from the air, and then wraps the insulating tape 3 on it to form a composite insulation protection structure of the electromagnetic wire. After the wrapping insulating tape 3 is wrapped on the electromagnetic wire, the formed gap 4 and the electromagnetic wire are covered by the insulating coating 2 isolation. The said brushing a layer of insulating layer on the surface of the magnet wire refers to brushing a layer of resin as the main material on the surface of the existing magnet wire, which is based on polytetrafluoroethylene-ethylene copolymer with certain elastic shrinkage properties. For the coating made of materials, in order to enhance the...

Embodiment 2

[0019] A method for wrapping an electromagnetic wire to prevent blackening, in which an insulating coating made of insulating material is applied on the surface of the existing electromagnetic wire, so that the electromagnetic wire is completely isolated from the air when it is wrapped, and then The insulation tape is wrapped around to form a composite insulation protection structure for the magnet wire. The said brushing a layer of insulating layer on the surface of the magnet wire refers to brushing a layer of resin as the main material on the surface of the existing magnet wire. The main material is polyetherimide resin with certain elastic shrinkage properties. The layer is directly brushed on the electromagnetic wire by brushing, and then wrapped with insulating tape to form a composite insulating layer of insulating coating and insulating tape. The thickness of the coating is between 0.1-0.5 mm.

Embodiment 3

[0021] A method for wrapping an electromagnetic wire to prevent blackening, in which an insulating coating made of insulating material is applied on the surface of the existing electromagnetic wire, so that the electromagnetic wire is completely isolated from the air when it is wrapped, and then The insulation tape is wrapped around to form a composite insulation protection structure for the magnet wire. The said brushing a layer of insulating layer on the surface of the magnet wire refers to brushing a layer of resin as the main material on the surface of the existing magnet wire. The main material is polyarylsulfone resin and polyarylether with certain elastic shrinkage performance The coating made of materials such as ketone resin or polytetrafluoroethylene-hexafluoropropylene copolymer can be brushed or plasma sprayed with aluminum oxide coating; the thickness of the coating is between 0.1-1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com