Method for manufacturing PCB (printed circuit board), PCB and device

A technology for printed circuit boards and sub-boards, which is applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, printed circuit components, etc., which can solve technical difficulties and limited application scenarios, etc. Problems, to achieve the effect of increasing layout density and applying a wide range of scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

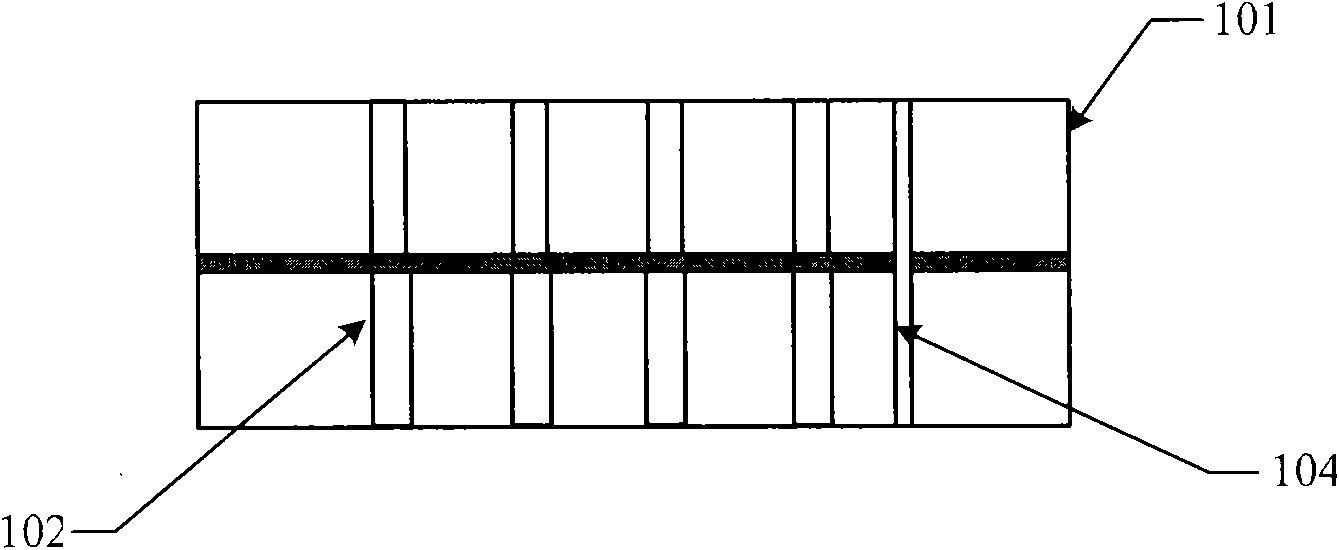

[0023] An embodiment of the present invention provides a printed circuit board. Embodiments of the present invention also provide a corresponding printed circuit board device assembled with a connector, and a method for manufacturing the printed circuit board. Each will be described in detail below.

[0024] A printed circuit board has blind holes on both sides, and the blind holes are used to press the pins of the connectors, so as to realize the pressing of the connectors on the two sides of the printed circuit board.

[0025] Since the holes on the printed circuit board used to press into the connector pins, that is, the crimping holes of the connector are blind holes, not only the pressure of the connectors on both sides of the printed circuit board can be realized, but also the connector pins can be realized. The signal isolation between them saves the layout space of the printed circuit board.

[0026] The printed circuit board can also have a via hole, which is used t...

Embodiment 2

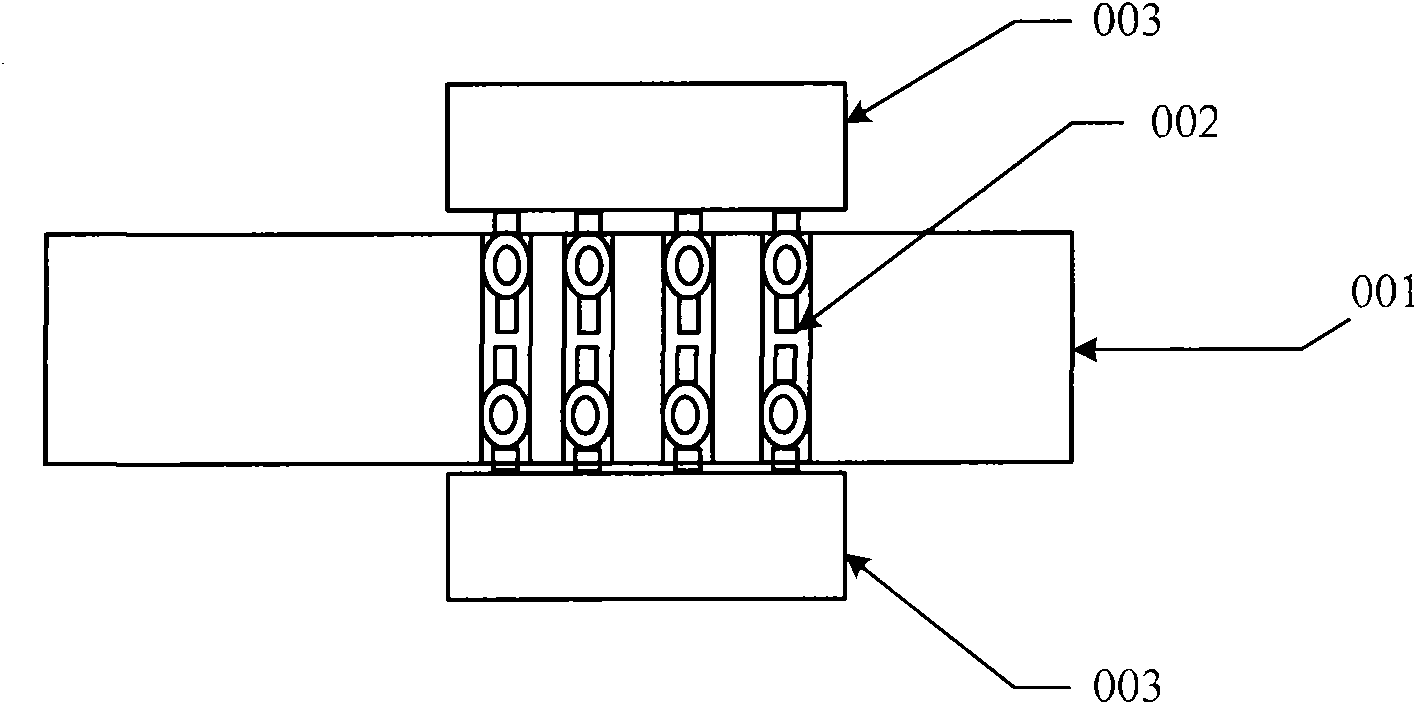

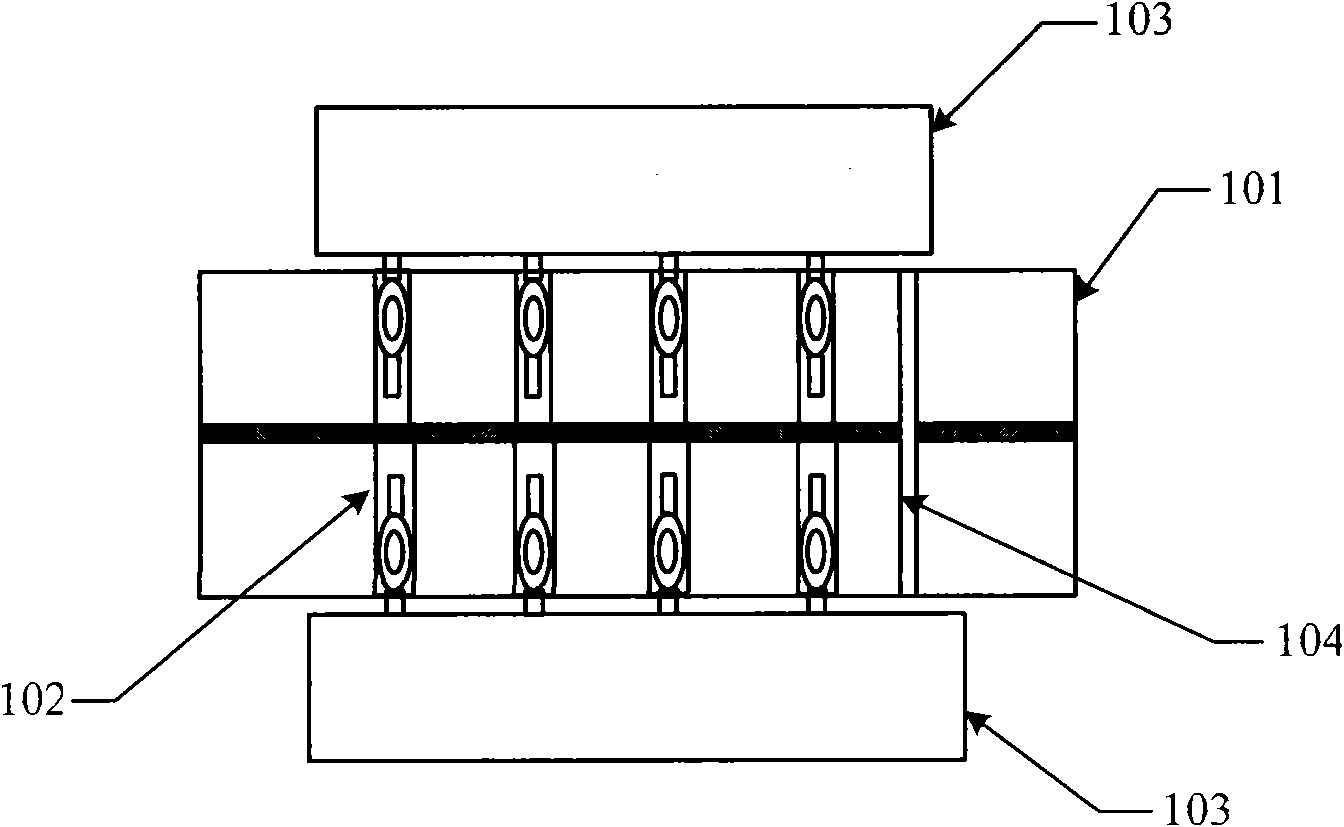

[0041] Correspondingly, the embodiment of the present invention also provides a printed circuit board device assembled with a connector, such as Figure 3 to Figure 7 As shown, the printed circuit board device assembled with a connector may include a connector 103 and any printed circuit board 101 provided by the embodiment of the present invention (see Embodiment 1 for details);

[0042] Both sides of the printed circuit board 101 have blind holes 102, and at least one pin of the connector 103 is pressed into the blind hole 102, so as to realize the opposite pressure with the connector 103 located on the other side of the printed circuit board 101. . Since the holes on the printed circuit board used to press into the connector pins, that is, the crimping holes of the connector are blind holes, not only the pressure of the connectors on both sides of the printed circuit board can be realized, but also the connector pins can be realized. The signal isolation between them saves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com