Device and method for spraying liquid material film based on ultrasonic vibration table

A material thin film, ultrasonic vibration technology, applied in the direction of liquid injection equipment, equipment for coating liquid on the surface, injection equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

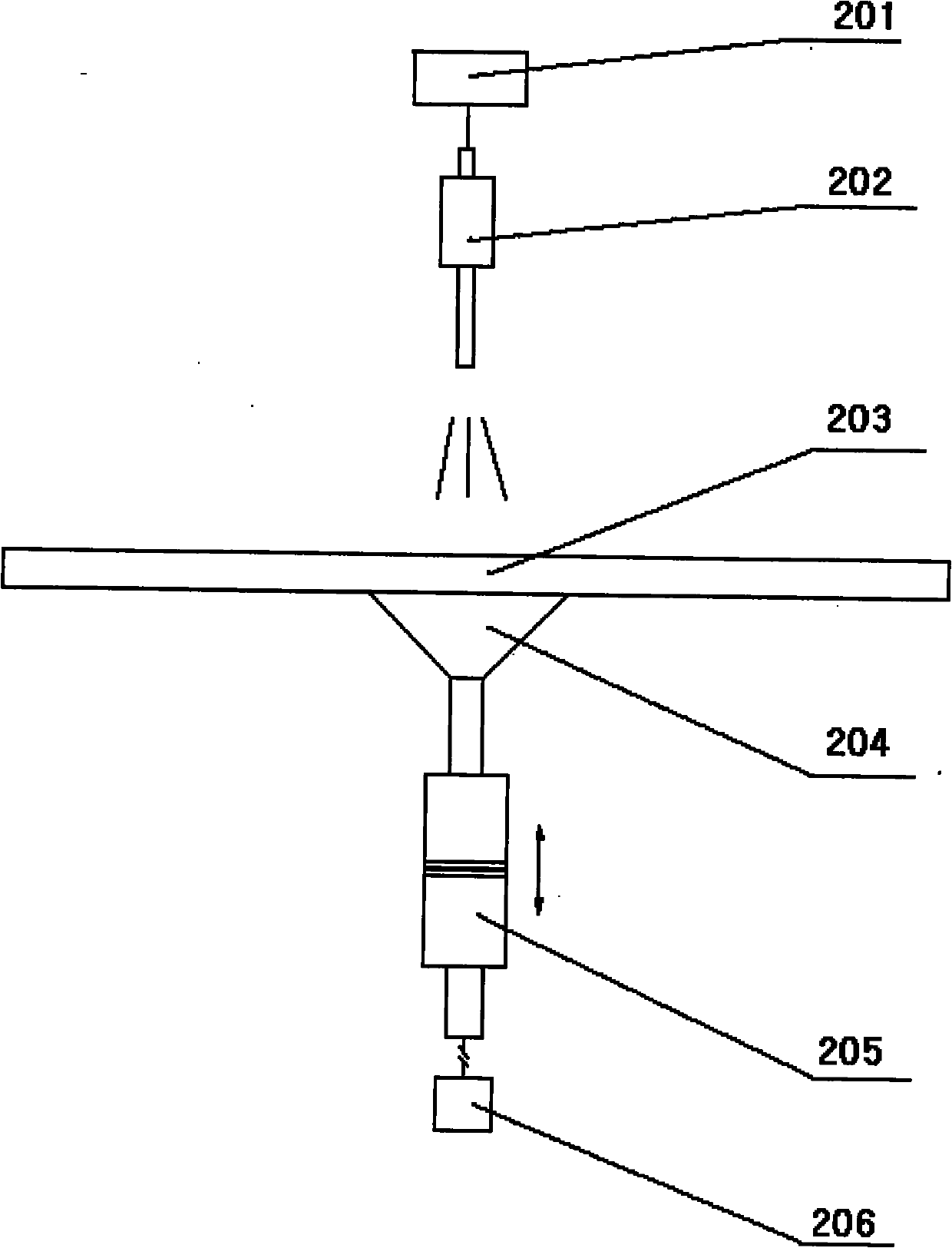

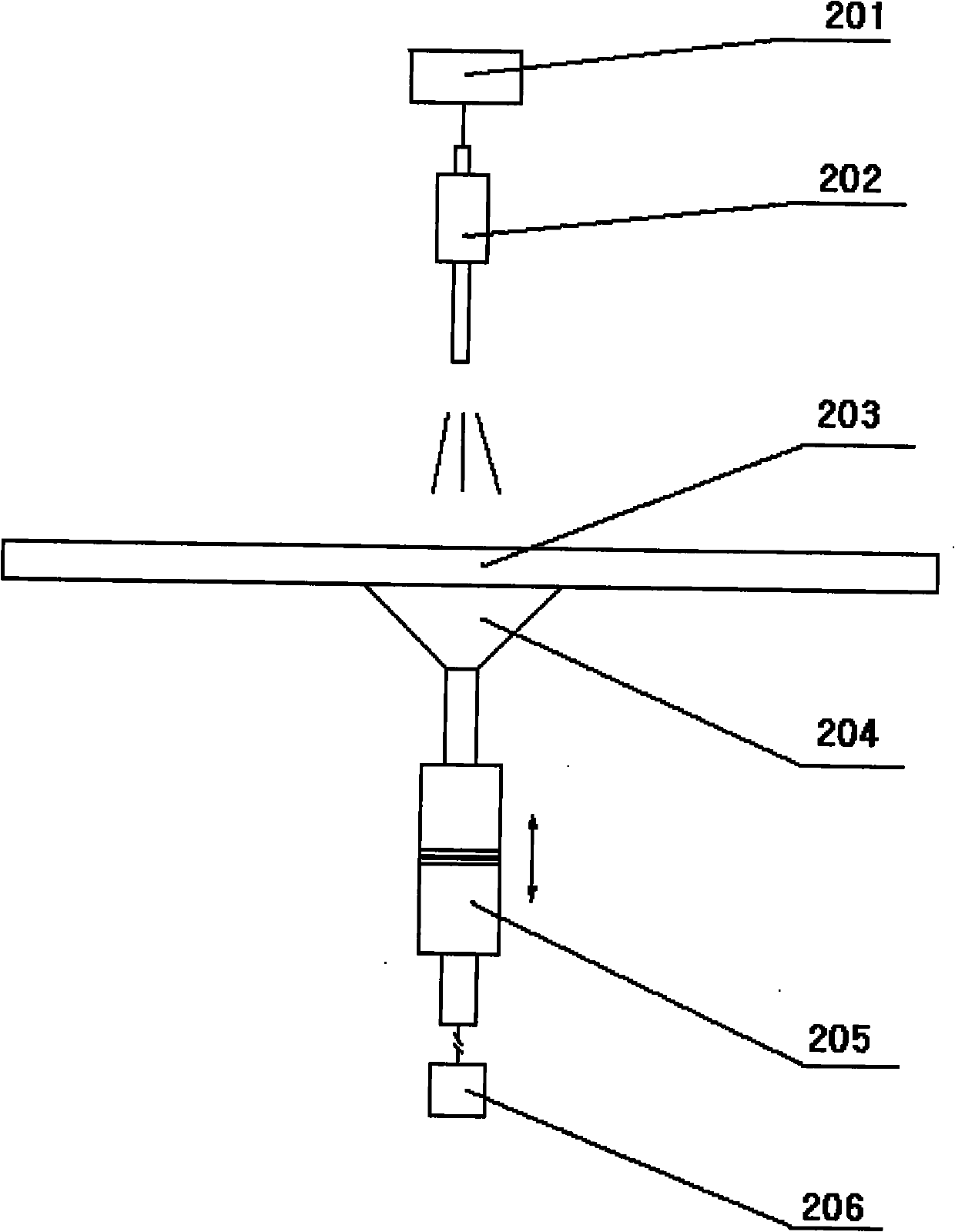

[0036] This embodiment takes photoresist film spraying as an example, and specifically describes the device and method for realizing photoresist film spraying according to the technical solution of the present invention.

[0037] The photoresist film spraying device based on the ultrasonic vibrating table provided according to the technical scheme of the present invention, such as figure 2 As shown, a liquid material film spraying device based on an ultrasonic vibrating table includes:

[0038] Ultrasonic atomizing nozzle 202, used for atomizing liquid to form fine droplets;

[0039] The nozzle moving mechanism 201 is connected to the ultrasonic atomizing nozzle 202, and is used to move the ultrasonic atomizing nozzle 202 to the spraying target area according to specific needs;

[0040] The device adsorption member 204 is arranged under the ultrasonic atomization nozzle 202, and is used to absorb and fix the substrate device 203 to be sprayed;

[0041] The ultrasonic vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com