Metal surface imprint forming device with direct local resistance heating

A local heating and metal surface technology, which is applied in the field of metal processing, can solve the problems of large energy consumption, low efficiency, and large strain area in workpiece processing, and achieve the effects of low energy consumption, high efficiency, and small processing strain area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

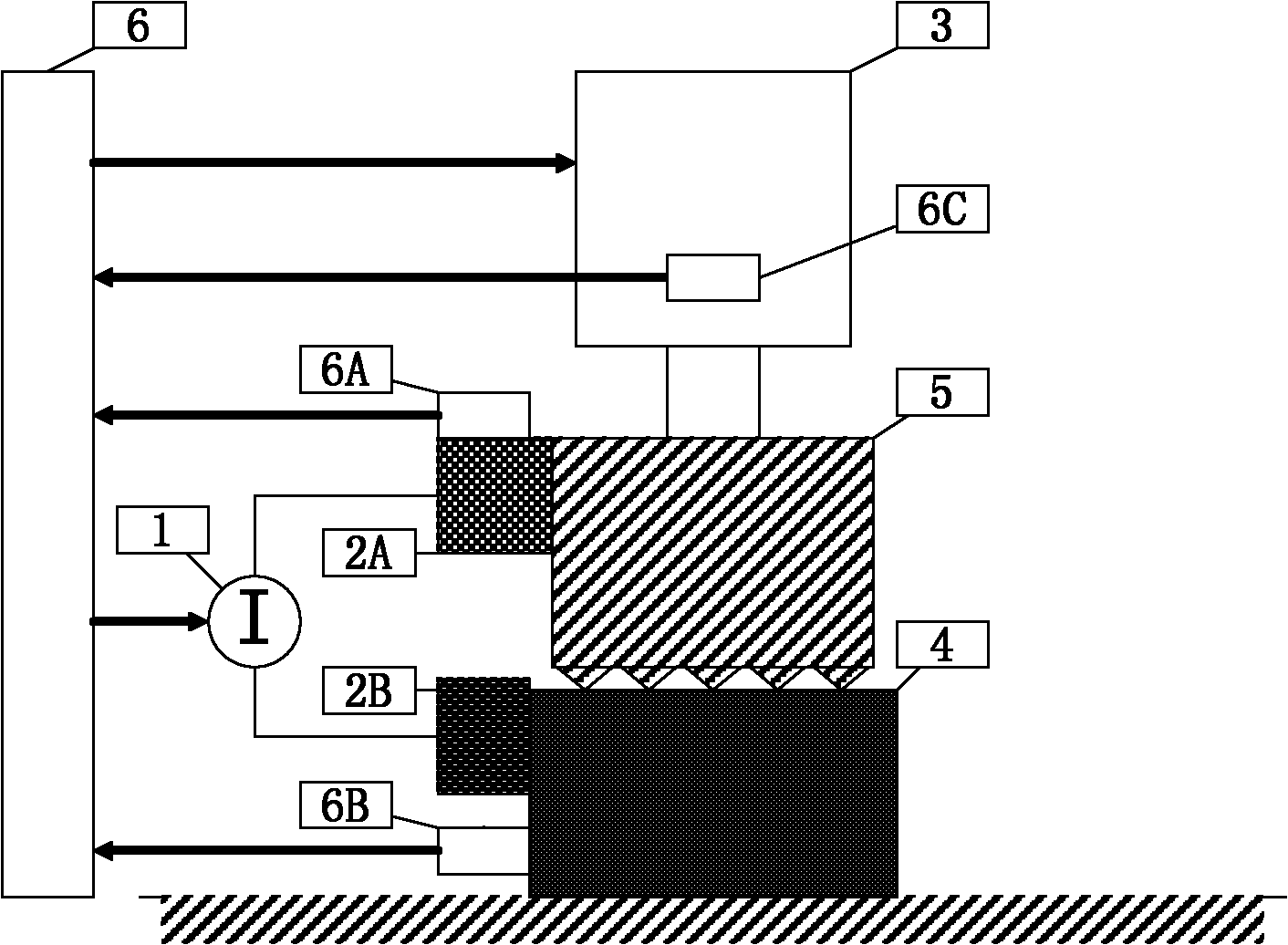

Embodiment 1

[0024] Such as figure 1 As shown, this embodiment includes: a power supply 1, a first electrode 2A, a second electrode 2B, an actuator 3 and a planar imprinting mold 5, a control system 6, a first sensor 6A, a second sensor 6B and a third sensor 6C , wherein: the power supply 1 is respectively connected to the first electrode 2A and the second electrode 2B to transmit current, the first electrode 2A is connected to the plane imprinting mold 5 to transmit current, the second electrode 2B is connected to the workpiece 4 to transmit current, and the plane The imprinting mold 5 is located directly above the workpiece 4, the actuator 3 is located directly above the plane imprinting mold 5 and is bolted to the plane imprinting mold 5 to transmit the pressure required for imprinting, the first sensor 6A and the first electrode 2A connected to transmit the temperature information of the first electrode 2A, the second sensor 6B is connected to the workpiece 4 to transmit the temperatur...

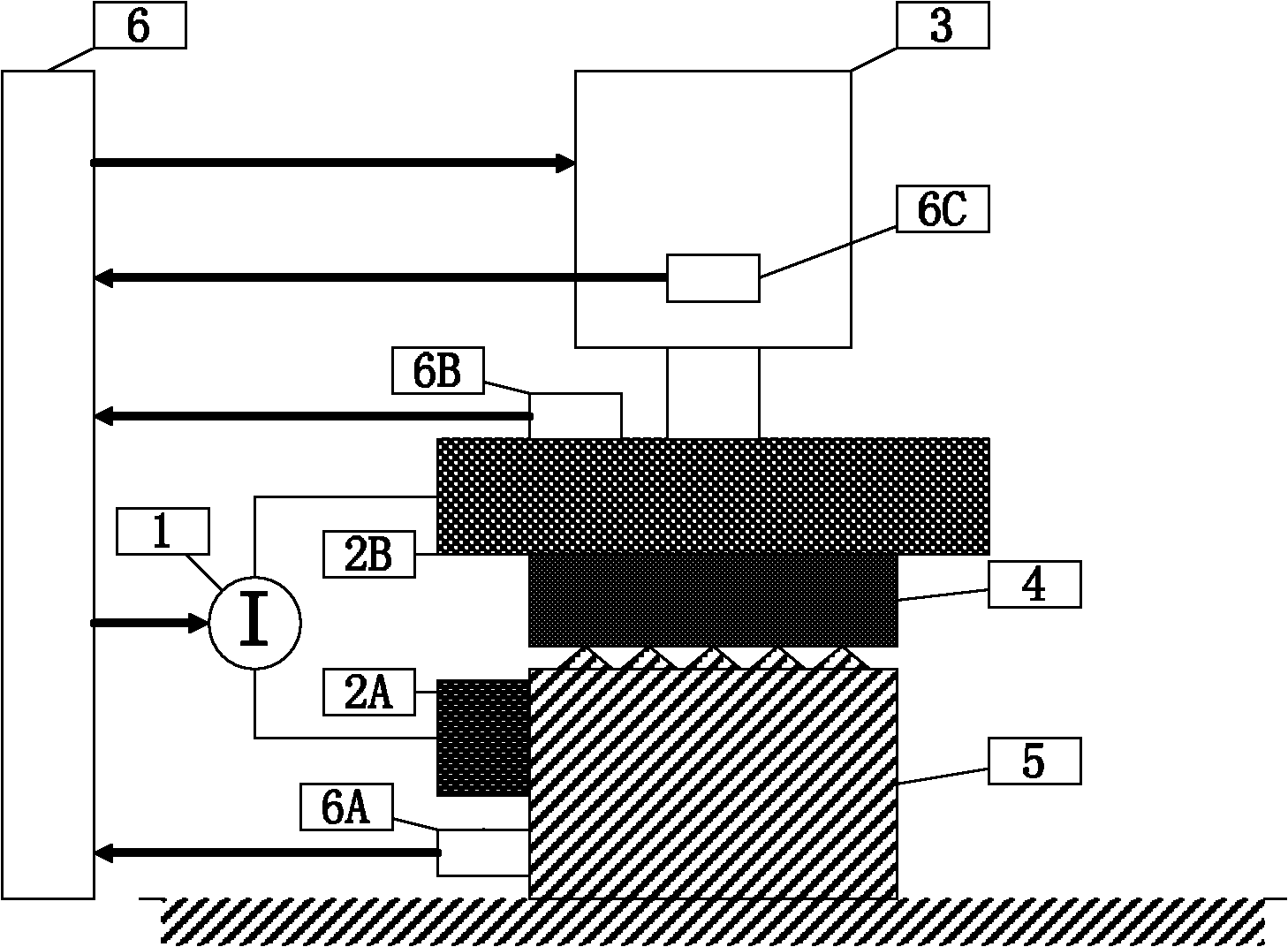

Embodiment 2

[0033] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the connection mode of the first sensor 6A and the second sensor 6B of the actuator 3 is different, wherein: the workpiece 4 is located directly above the planar imprinting mold 5, and the second electrode 2B It is located directly above the workpiece 4 and is in contact with the workpiece 4 to transmit current. The actuator 3 is located directly above the second electrode 2B and is bolted to the second electrode 2B to transmit the pressure required for imprinting. The first sensor 6A is in contact with the plane press. The stamping mold 5 is connected to transmit the temperature information of the planar imprinting mold 5, the second sensor 6B is located on the second electrode 2B and connected to the second electrode 2B to transmit the temperature information of the second electrode 2B, and the third sensor 6C is connected to the actuator 3 The pressure information of the actua...

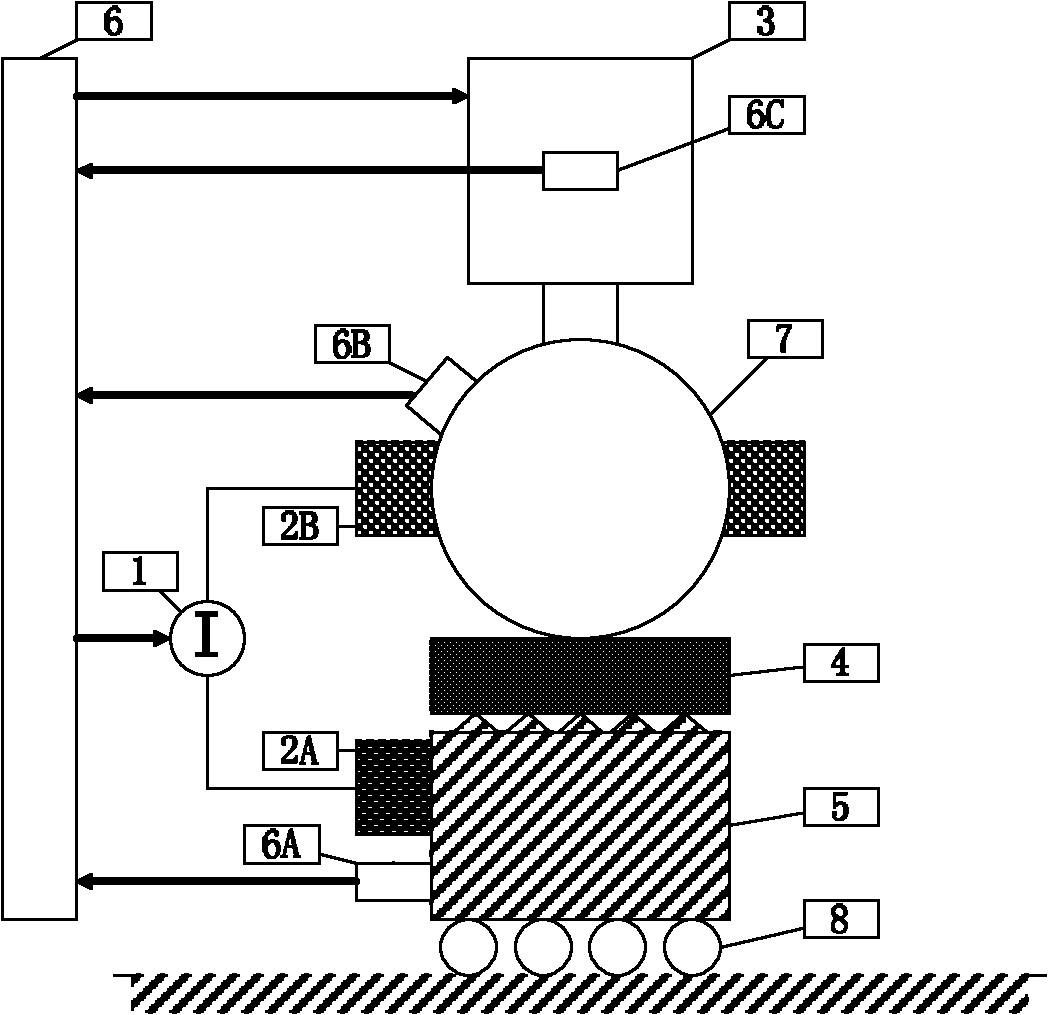

Embodiment 3

[0040] Such as image 3 As shown, the difference between this embodiment and Embodiment 2 is that the extruding device of this embodiment is a plane embossing mold 5 and a roller mold 7, and this embodiment also includes: a sliding module 8, wherein: the second electrode 2B Contacting and connecting with the roll mold 7 distributes the current on the roll mold, the second sensor 6B is connected with the roll mold 7 to transmit the temperature information of the roll mold, and the actuator 3 is bolted to the support structure of the roll mold 7 to control The movement of the vertical direction of the roll mold 7, the lower end of the roll mold 7 is in contact with the workpiece 4 to distribute the current on the workpiece 4 and make the downward force act on the workpiece 4, the sliding module 8 is located on the ground and pressed against the plane. The lower part of the imprinting mold 5 is in contact with each other so that the plane imprinting mold 5 can move horizontally. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com