Knitting needle bed swinging mechanism of high-speed tricot machine

A high-speed warp knitting machine and warp knitting machine technology, which is applied in the directions of warp knitting, knitting, textiles and papermaking, can solve the problems of difficult processing and manufacturing of cam mechanisms, unsuitable high speed of cam mechanisms, and limiting the speed of warp knitting machines. Easy to manufacture, wide range of travel speed ratio coefficients, easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

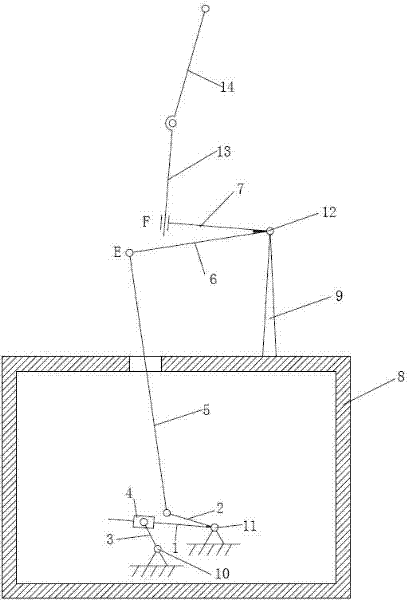

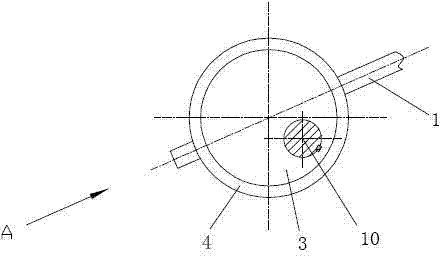

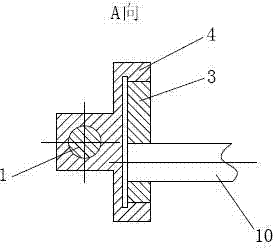

[0018] In the embodiment shown in the accompanying drawings, the oil tank 8 of the warp knitting machine is provided with a main shaft 10 and a bearing pin 11 which are respectively supported by a support frame and are parallel to each other, and the oil tank 8 of the warp knitting machine is provided with a pendulum shaft 12 supported by a bracket 9 and a weaving pin. The needle bed 14 and the needle bed seat 13 supporting the needle bed 14. The main shaft 10, pin shaft 11 and swing shaft 12 are all long axes equal to the width of the machine. The main shaft 10 is the main movement power input shaft of the warp knitting machine, driven by a motor. The needle bed active swing arm 6 and the needle bed driven swing arm 7 are fixed on the swing shaft 12 , and the needle bed active swing arm 6 and the needle bed driven swing arm 7 swing as a whole with the rotation of the swing shaft 12 . The needle bed seat 13 is inserted in the guide cylinder 7-1 of the driven swing arm 7 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com