Fuel economizer of rich oxygen type fuel engine controlled by single chip

A technology controlled by a fuel engine and single-chip microcomputer, which is used in combustion engines, machines/engines, internal combustion piston engines, etc. to achieve the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

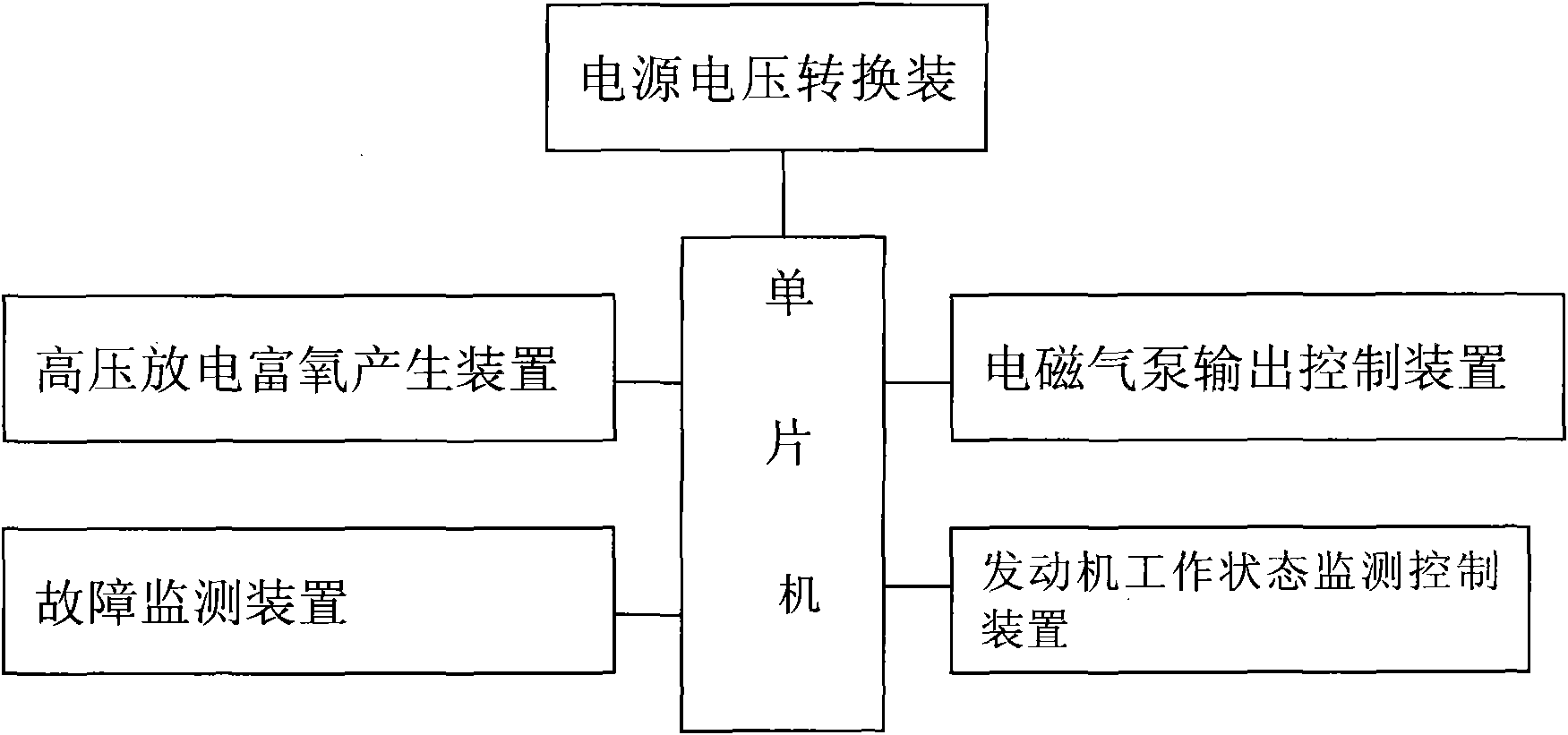

[0025] This embodiment includes a single-chip microcomputer, a high-voltage discharge oxygen-enriched generating device, an electromagnetic air pump output control device, a fault monitoring device, and an engine working state monitoring and control device. The single-chip microcomputer is provided with four measurement and control terminals and a power input terminal. The power supply voltage conversion device is connected to the generator port of the fuel engine or the battery port for starting the engine, or to a dedicated 5-volt power supply, and the four measurement and control terminals are respectively connected to the output frequency control terminal of the power amplifier of the high-voltage discharge oxygen-enriched generating device, the electromagnetic The control end of the air pump output control device, the signal input end of the fault monitoring device and the input end of the engine working state monitoring control device are connected.

[0026] When the freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com