Method for preparing road base material cylindrical test piece simulating on-site rolling effect

A technology of road base and cylinder, which is applied in the field of traffic civil engineering, can solve problems such as structure, gradation, water content, cement dosage, compactness, non-compliance with conditions, complicated operation, etc., and achieve objective and true test results. The effect of simplifying the loading process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] According to the technical scheme of the present invention, the preparation method of the cylinder specimen of the road (bottom) base material of the simulated on-site rolling effect of the present embodiment takes no inorganic binder as an example, that is, the dosage of the inorganic binder is 0, and the prepared grade The compactness of the crushed stone test piece is 98%, and its preparation method is carried out according to the following steps:

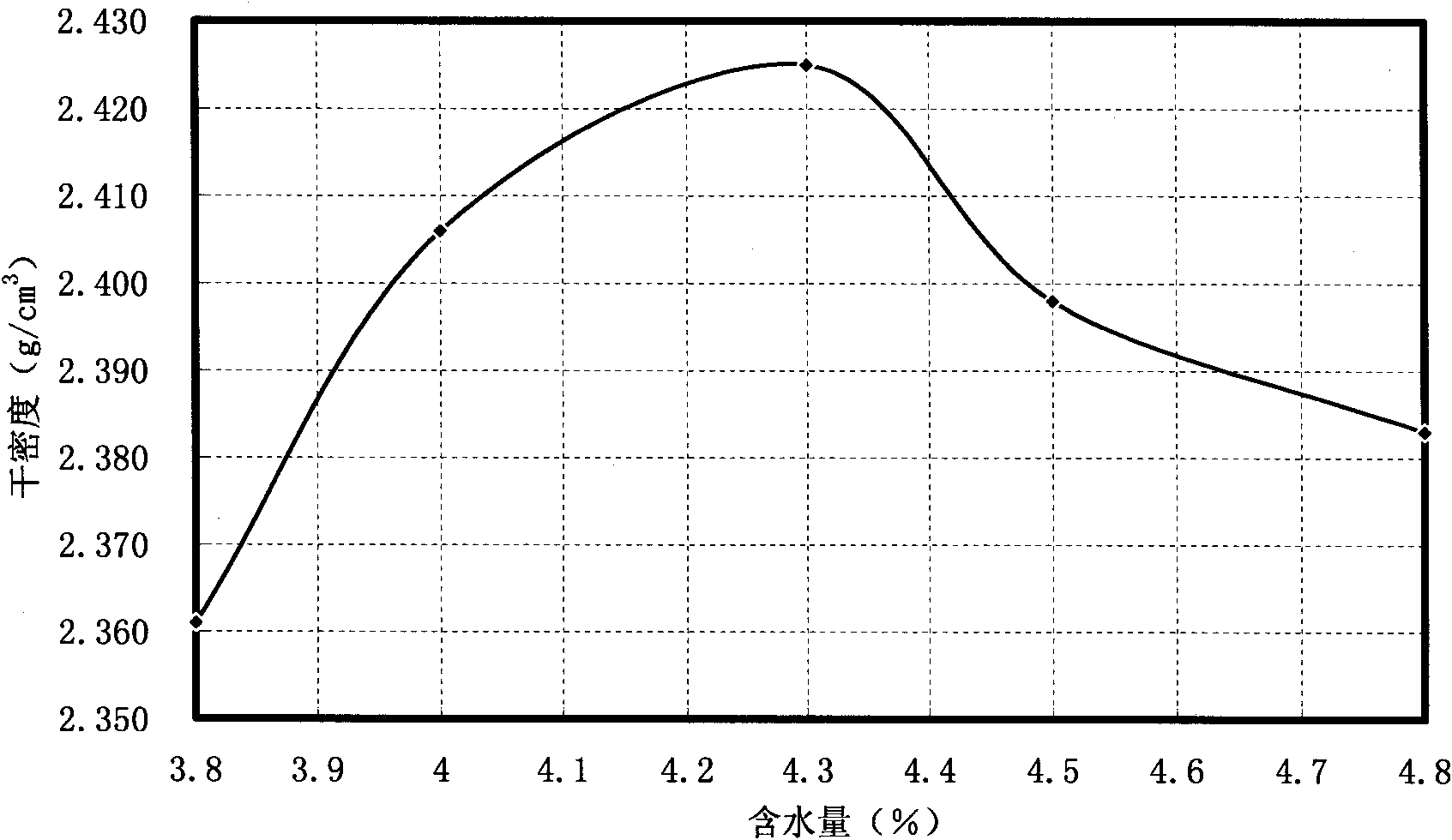

[0082] 1) Vibration compaction test method to determine the maximum dry density ρ dmax and the optimum water content w o

[0083] ① Place the limestone sample used in the test in an oven with a temperature of 105°C for 5 hours.

[0084] ②During the first test, take the dried sample m s =5200g, spread it on a metal plate and stir evenly to obtain a dry mixture;

[0085] ③In the first test, the water content of mixing is 4.0%, that is, add 5200×0.04=208g of water to evenly spray on the dry mixture and mix evenly to obta...

Embodiment 2

[0105] According to the technical scheme of the present invention, the preparation method of the cylinder specimen of the highway (bottom) base material of the simulated on-site rolling effect of the present embodiment takes the inorganic binder as cement as an example, and the cement dosage is 4%, and the prepared cement is stably crushed The degree of compaction of the stone test piece is 99%, and its preparation method is carried out according to the following steps:

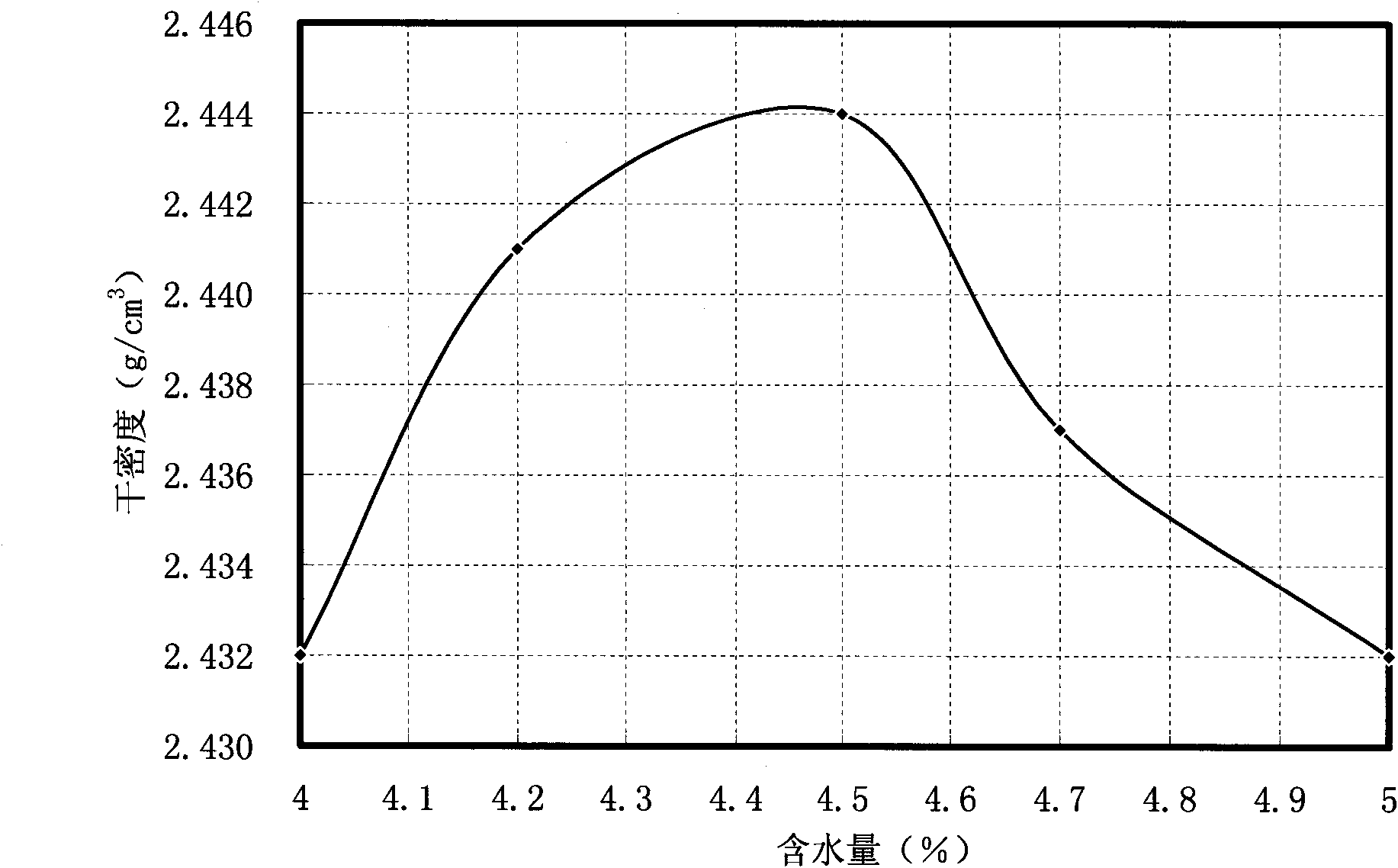

[0106] 1) Vibration compaction test method to determine the maximum dry density ρ dmax and the optimum water content w o

[0107] ① Place the andesite sample used in the test in an oven with a temperature of 105°C for 5 hours.

[0108] ② In the first test, take m s = 1 part of 5000g dried sample, spread it on a metal plate, and add 4.0% cement dosage, that is, the cement dosage is m j = 5000 1 - 0.04 ...

Embodiment 3

[0128] According to the technical scheme of the present invention, the method for preparing the cylinder specimen of the highway (bottom) base material cylinder for simulating the on-site rolling effect of the present embodiment, is lime fly ash (abbreviated as fly ash) as an example with the inorganic binder, and the dose of fly ash 25%, the compactness of the prepared fly ash stabilized crushed stone specimen is 97%, and its preparation method is carried out according to the following steps:

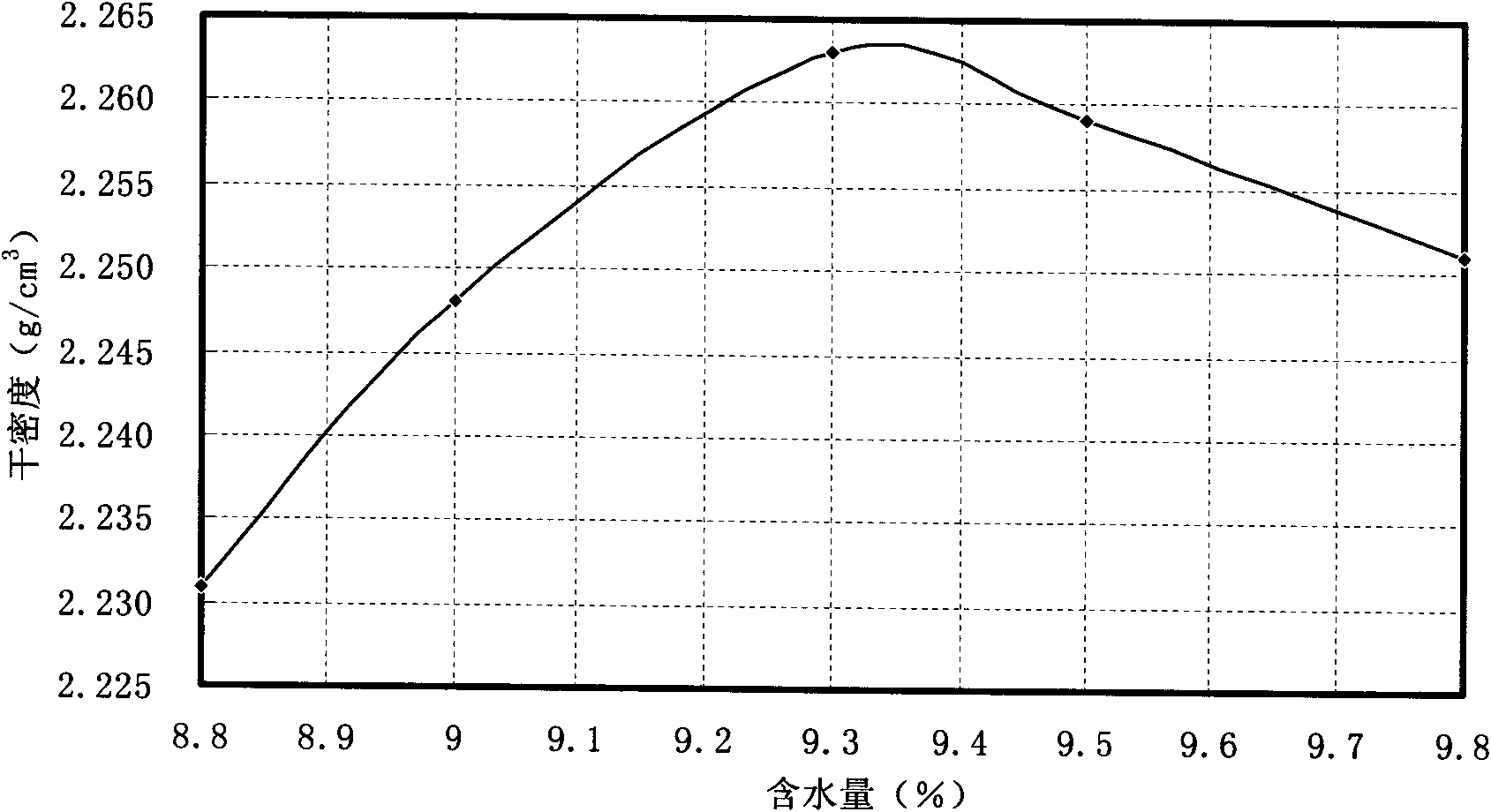

[0129] 1) Vibration compaction test method to determine the maximum dry density ρ dmax and the optimum water content w o

[0130] ① Place the granite sample used in the test in an oven with a temperature of 105°C for 5 hours.

[0131] ② In the first test, take m s = 1 part of 4000g dried test material, lay it flat on a metal plate, and add 25% of lime fly ash, that is, the amount of lime fly ash is 1333g, mix evenly to obtain a dry mixture.

[0132] ③In the first test, take the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com