Vision device of solar cell back silver printing equipment

A technology for solar cells and printing equipment, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as restricting the increase in production capacity and yield of production lines, restricting the improvement of repeated printing accuracy of production lines, and being easily broken. , to achieve the effect of improving repeat printing accuracy, increasing productivity and yield, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

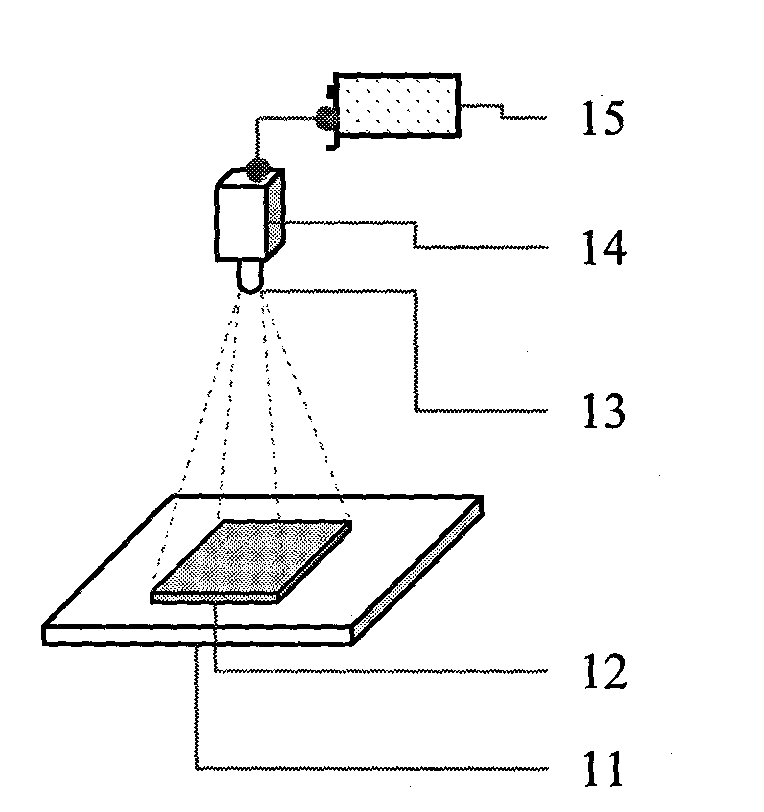

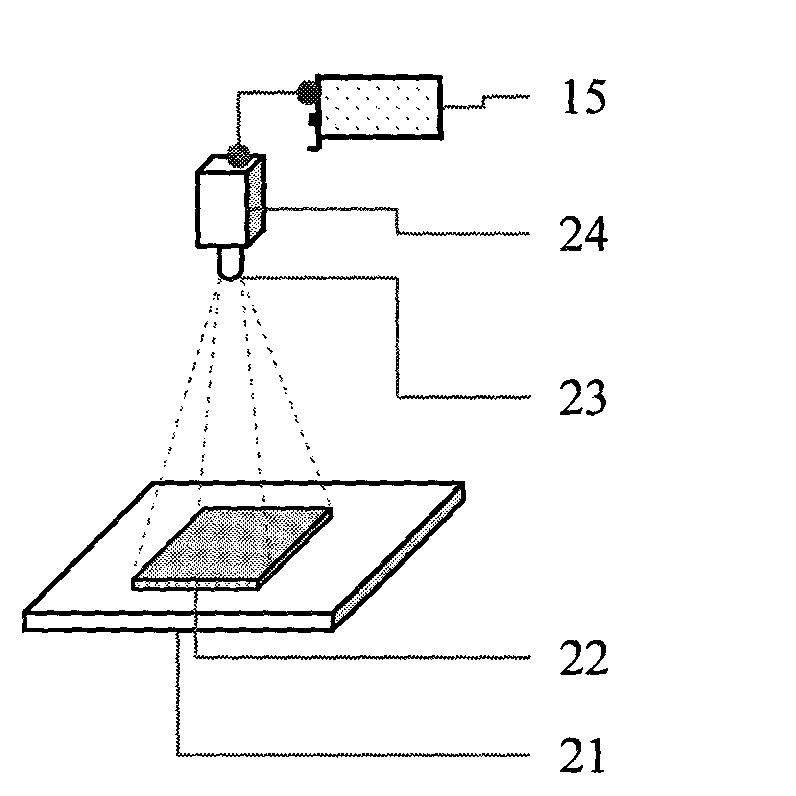

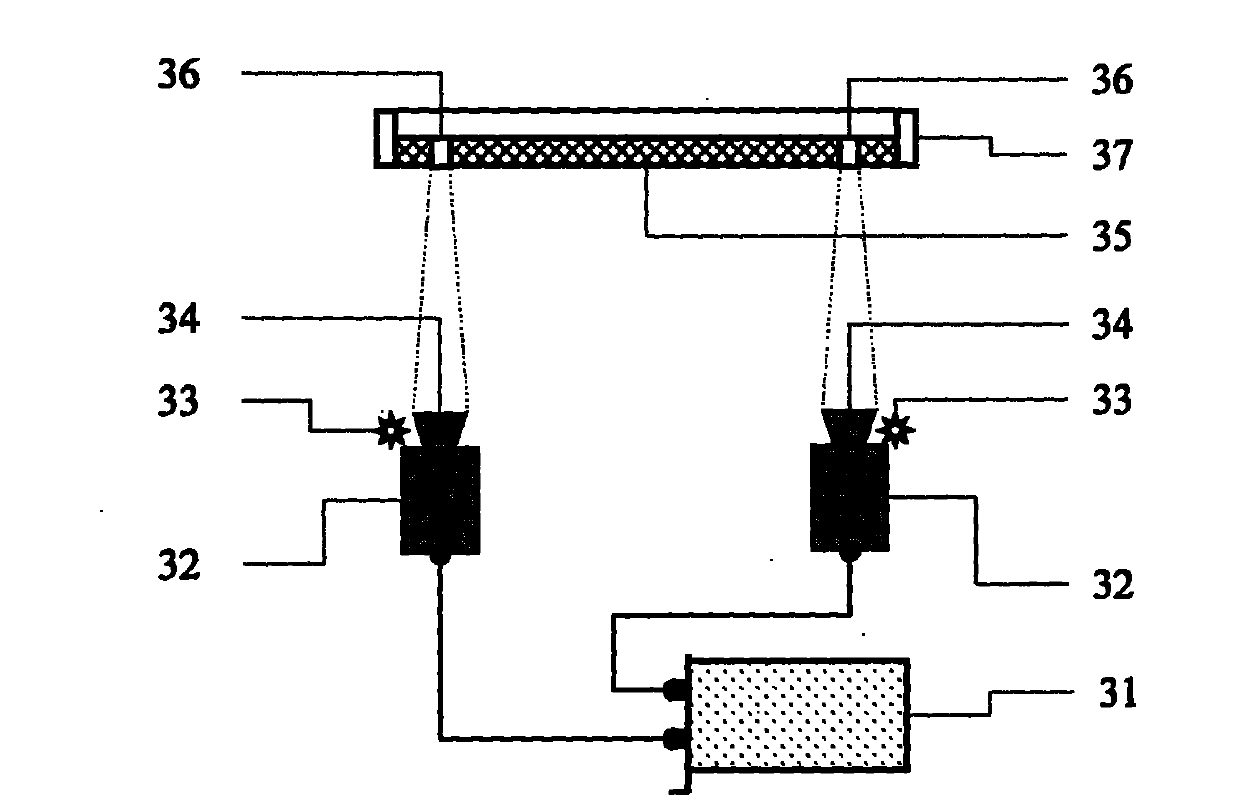

[0024] see Figure 1 to Figure 11 , The visual device of solar cell printing back silver equipment has three mechanisms: pre-press visual imaging and its collection and processing mechanism, post-press visual imaging and its collection and processing mechanism, screen alignment imaging and its collection and processing mechanism. The imaging and its collection and processing mechanism are pre-press visual imaging and its collection and processing mechanism. The first camera 14 of 13 is placed directly above the preprinted cell 12 of the detected object; the first camera 14 is connected with the first video capture card 15; Chip defect detection module and man-machine interface are composed of three parts. The imaging and its collection and processing mechanism are post-press visual imaging and its collection and processing mechanism. The second camera 24 is placed directly above the printed cell 22 of the object to be detected; the second camera 24 is connected to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com