Electromagnetic heating device of iron finishing roller of iron finishing machine

A technology of electromagnetic heating device and ironing roller, which is applied in the direction of induction heating device, induction heating, textile and paper making, etc., which can solve the problems of difficult maintenance, slow heating speed, and low service life, and achieve the purpose of improving heat utilization rate and heating The effect of fast speed and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

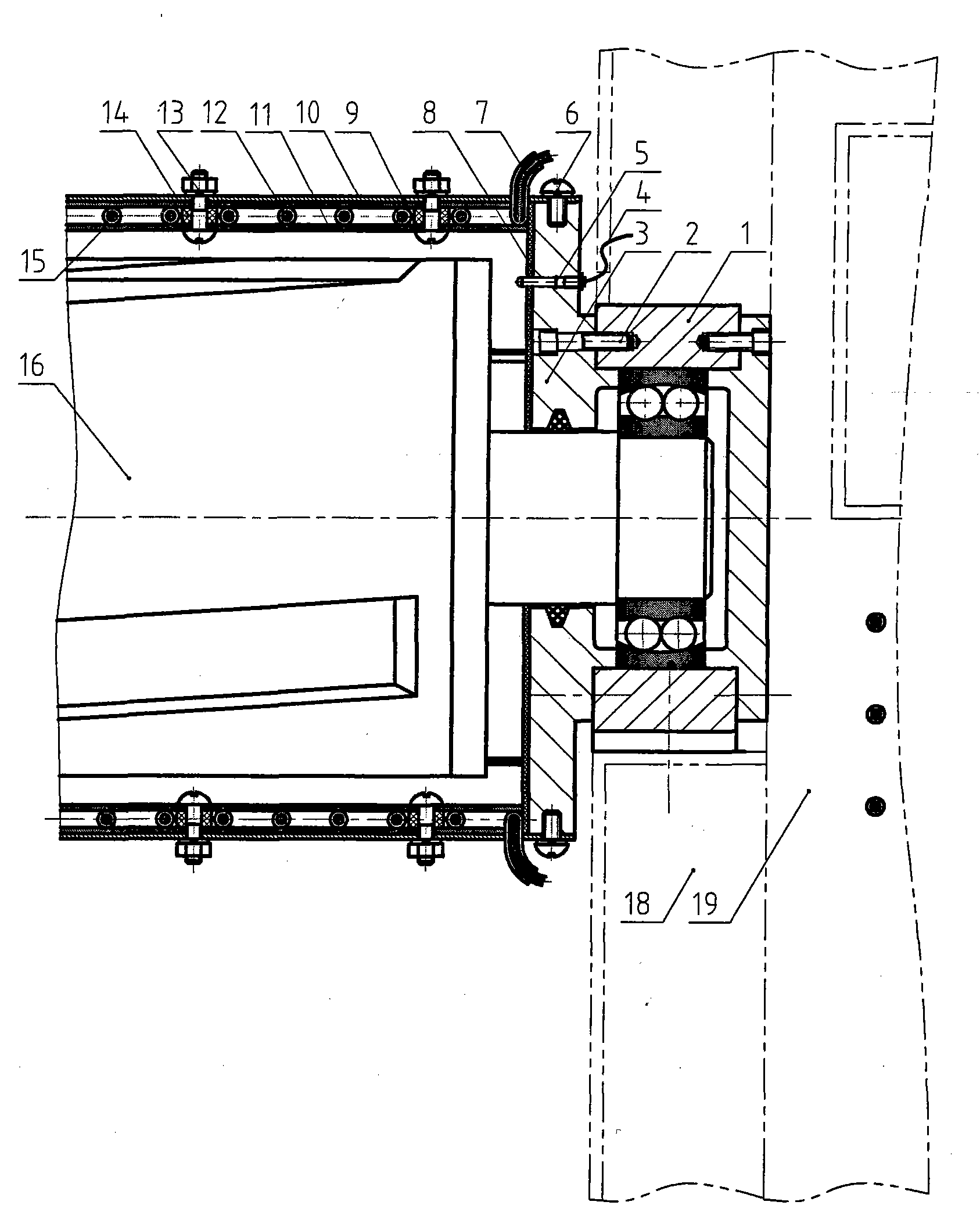

[0020] The ironing roller 16 is installed between the left and right racks 18 by two bearing seats 1. The outer side of the rack 18 is provided with an electric control box 19 containing electrical components such as an electromagnetic heating controller, a digital display screen and a power adjustment switch.

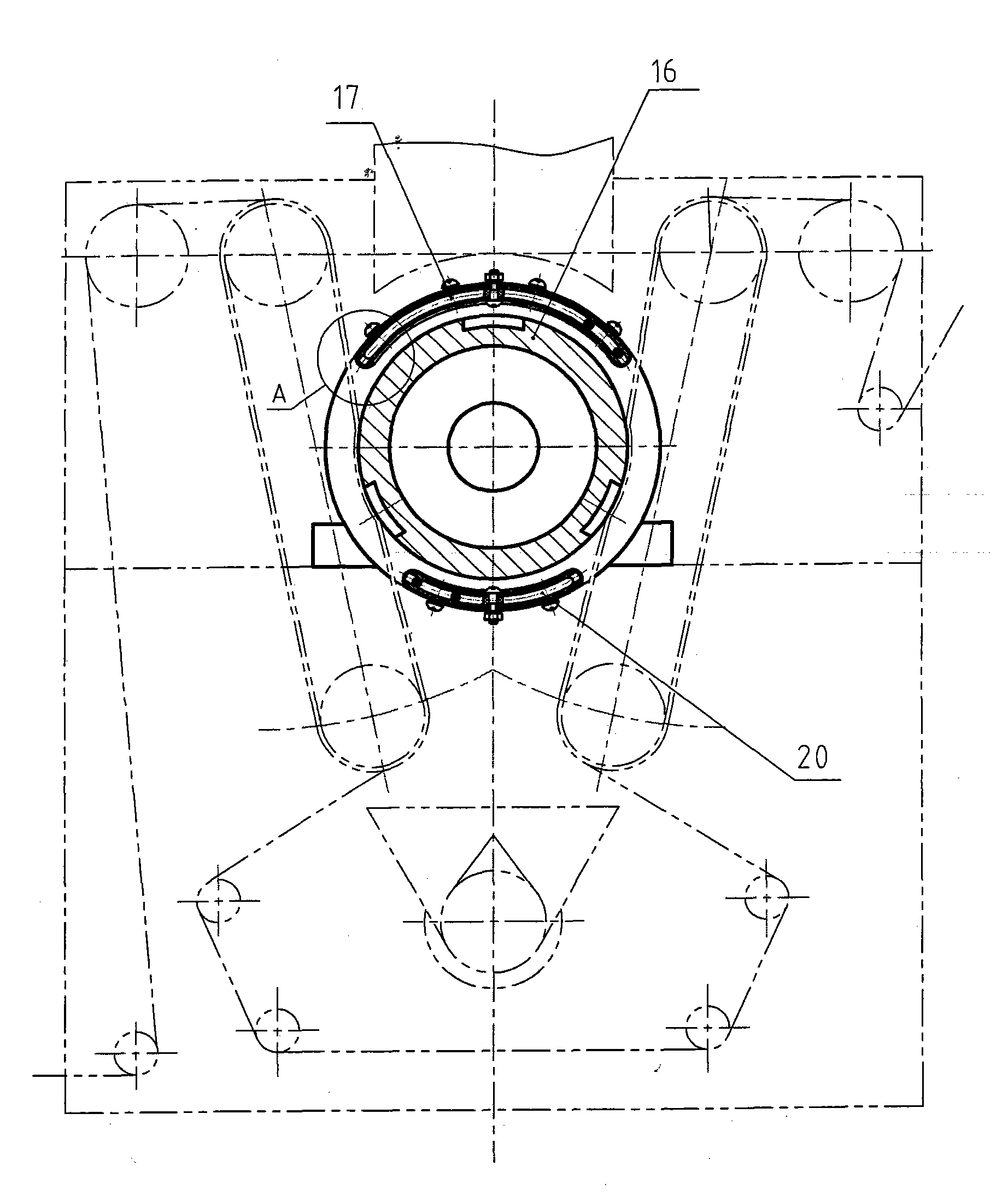

[0021] The present invention mainly includes an upper heating mantle assembly 17 and a lower heating mantle assembly 20. The upper and lower heating mantle assemblies 17 and 20 are arc-shaped, symmetrically arranged on the upper and lower sides of the ironing roller 16, and fixed to the two ends by screws 6. end cap 3. The end caps 3 are arranged on the inner side of the bearing seats 1 at both ends of the ironing roller 16 , and are fixed on the bearing seats 1 by screws 2 .

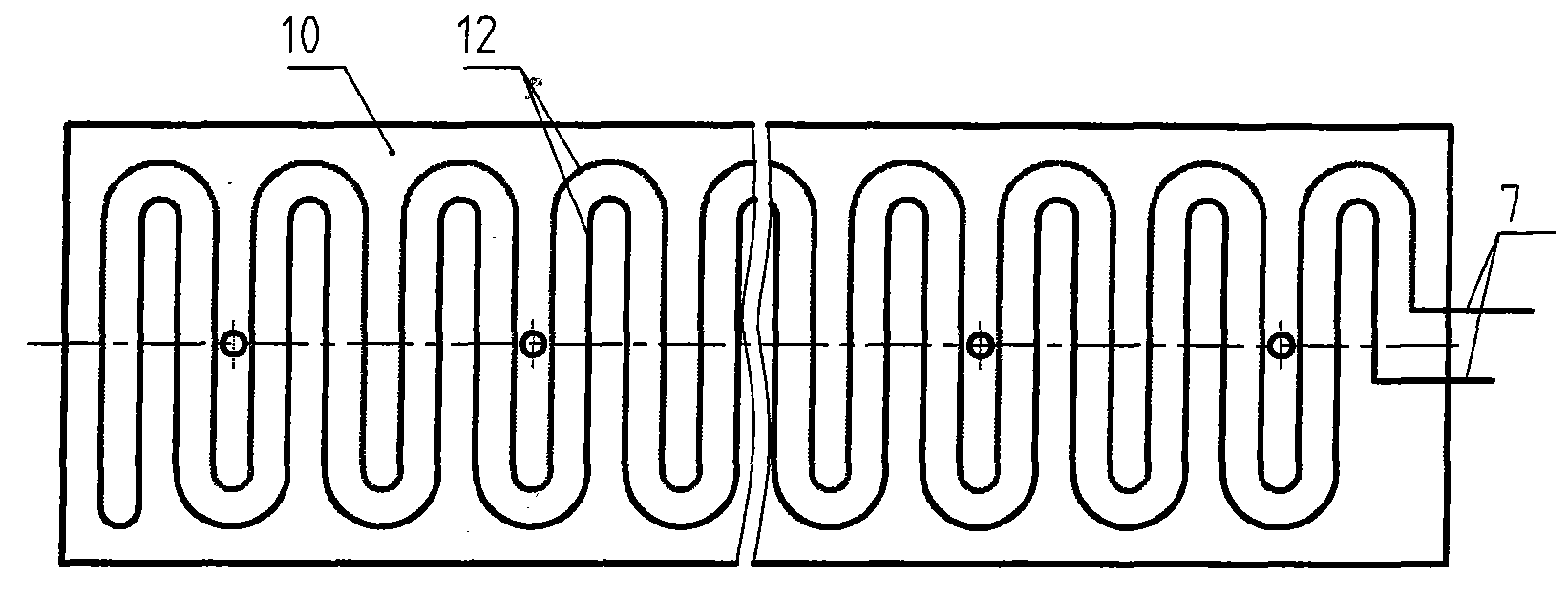

[0022] The upper and lower heating cover assemblies 17 and 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com