Optical film with adhesive and optical laminate

A technology of adhesive layer and optical film, which is applied in the field of optical film, can solve the problems of whitening, whitening of the outer periphery, uneven residual stress distribution of optical film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

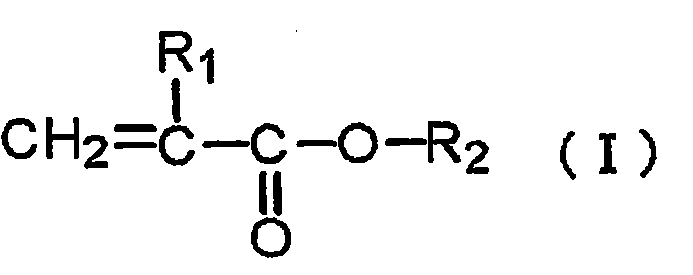

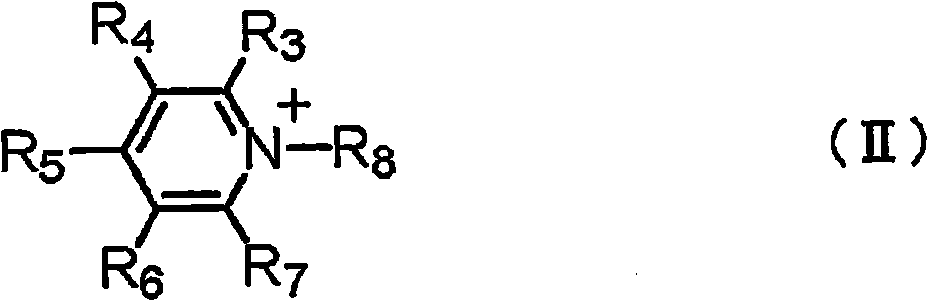

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~3

[0246] (a) Manufacture of adhesive

[0247] The acrylic resins A1 to A4 obtained in Polymerization Examples 1 to 4 were respectively used in an amount of 100 parts in terms of non-volatile components, and the above-mentioned ionic compounds, acrylic resins, and acrylic resins were mixed therein at the ratios shown in Table 1, respectively. A bonding agent and a silane compound are used to prepare an adhesive composition. However, the compounding quantity (part) of a crosslinking agent in Table 1 is the quantity of solid content.

[0248] Table 1

[0249]

[0250] *Meaning of the symbols in the monomer composition column of acrylic resin

[0251] BA: butyl acrylate

[0252] HEA: 2-Hydroxyethyl Acrylate

[0253] HBA: 4-Hydroxybutyl Acrylate

[0254] AA: Acrylic

[0255] The numbers following "HEA", "HBA" and "AA" indicate the content (%) of the monomer unit in the acrylic resin.

[0256] (b) Fabrication of optical film with adhesive

[0257] Each of the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com